Polymer microporous material and preparation method based on organic polymer network structure

A technology of network structure and microporous material, which is applied in the field of polymer microporous materials and preparation methods based on organic polymer network structure, can solve the problems of difficult pore size controllable polymer microporous materials, narrow technical application area, etc. The effect of wide range, flexible preparation process and stable pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

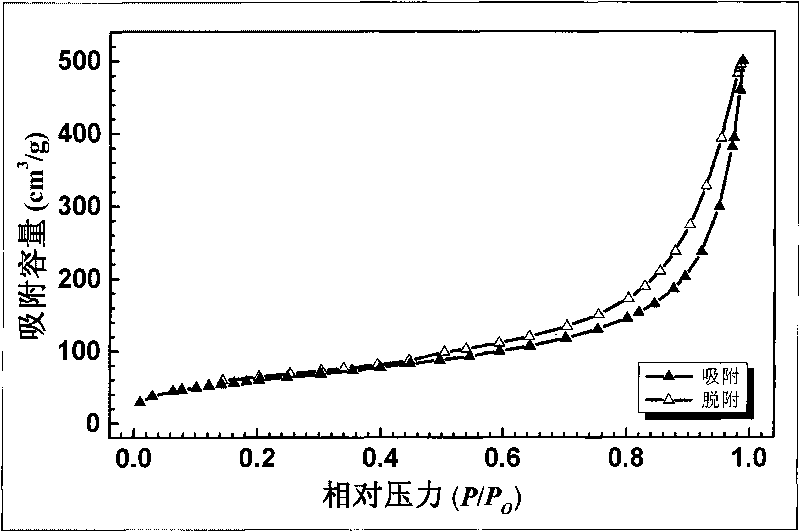

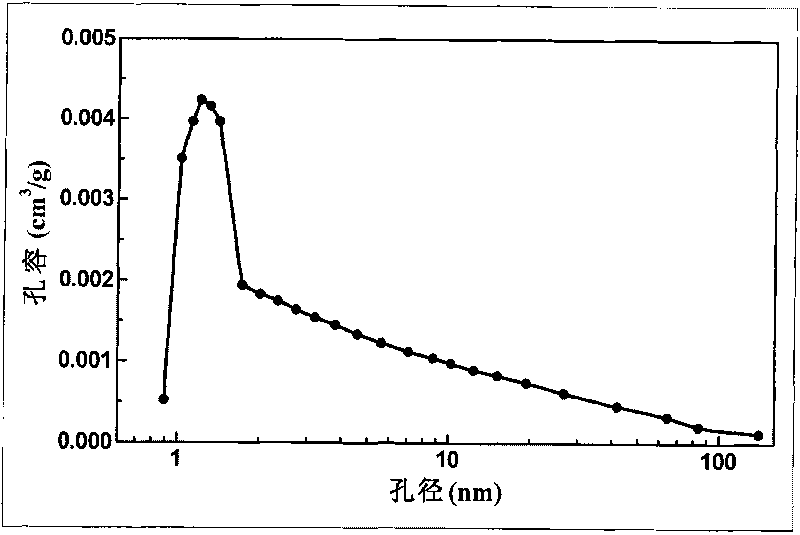

Image

Examples

Embodiment 1

[0018] Add 264.3mg 3,3'-dimethyl-4,4'-diisocyanate biphenyl to a reaction vessel, and protect the reaction vessel with nitrogen gas, then add 4mL of dry treated dimethylformamide to the reaction vessel sulfoxide solvent, stirring to dissolve the solid completely; dissolving 126.2mg melamine in 5mL dry-treated dimethyl sulfoxide solvent to obtain a clear solution, and adding the solution dropwise to 3,3'-dimethylsulfoxide under nitrogen protection -4,4'-diisocyanate biphenyl solution, the resulting reaction solution was stirred at room temperature for three days; after the reaction, the precipitated white solid was centrifuged, and the solid was washed with dimethyl sulfoxide and methanol in sequence After several times, the obtained white solid was sequentially extracted with methanol and chloroform for 48 hours in a Soxhlet extractor to obtain a white block polymer microporous material based on an organic polymer network structure of the present invention. The melamine descri...

Embodiment 2

[0020] Add 160.2 mg of 1,4-diisocyanatobenzene into a reaction vessel, and protect the reaction vessel with nitrogen gas, then add 4 mL of dry-processed dimethyl sulfoxide solvent into the reaction vessel, and stir to allow the solid to dissolve completely; 126.4mg of melamine was dissolved in 4mL of dry treated dimethyl sulfoxide to obtain a clear solution, and the solution was added dropwise to the solution of 1,4-diisocyanobenzene under the protection of nitrogen, and the resulting reaction solution was heated at room temperature Stir for three days; after the reaction, centrifuge the precipitated white solid, wash the solid with dimethyl sulfoxide and methanol several times, and extract the white solid with methanol and chloroform in a Soxhlet extractor for 48 hours , to obtain the white block polymer microporous material based on the organic polymer network structure of the present invention. The melamine described in this embodiment is a stereomolecule, and 1,4-diisocyan...

Embodiment 3

[0022] In a reaction vessel, add 68.4mg hexahydroxytriptycene and 215.3mg 3,3'-dimethyl-4,4'-diisocyanate biphenyl, and the reaction vessel is protected by nitrogen gas; then in the reaction vessel Add 8 mL of dry treated N,N'-dimethylformamide solvent, stir to completely dissolve the solid to obtain a clear solution, then add 0.3 mL of dried triethylamine to the reaction solution, and the solution quickly turns into a gel shape. Heat the gel to 50°C for 48 hours to turn into a powdery mixture, filter the mixture to obtain a brown solid, wash the solid several times with methanol and chloroform successively, and then extract with methanol and chloroform in a Soxhlet extractor for 48 hours , to obtain the light brown polymer microporous material based on the organic polymer network structure of the present invention. The hexahydroxytriptycene described in this example is a stereomolecule, and 3,3'-dimethyl-4,4'-diisocyanatobiphenyl is a fused-ring aromatic hydrocarbon molecule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com