Method for preparing soil conditioner by carrying out carbonization treatment on lake substrate sludge

The technology of soil conditioner and sediment is applied in the field of resource utilization of lake sediment, which can solve the problems of large amount of engineering, inconvenience and high cost, and achieve the effect of eliminating potential harm and controlling pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

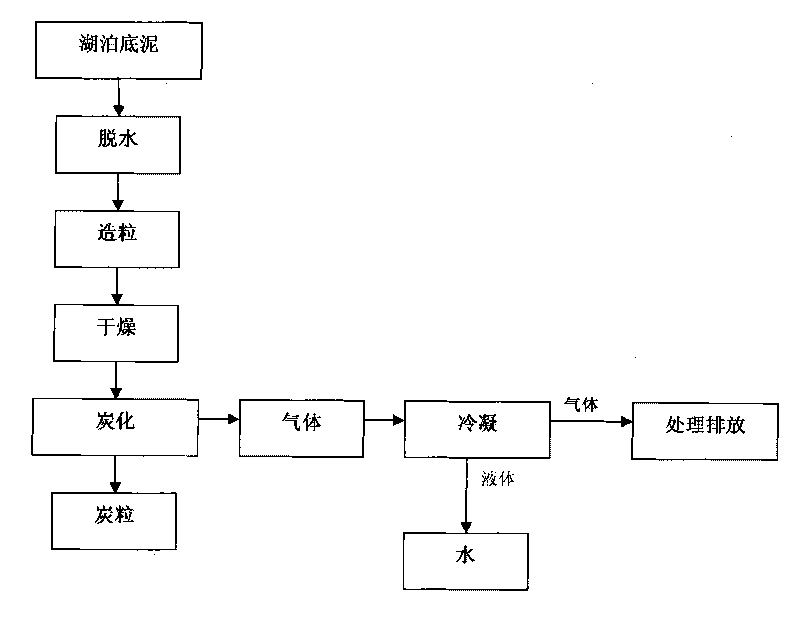

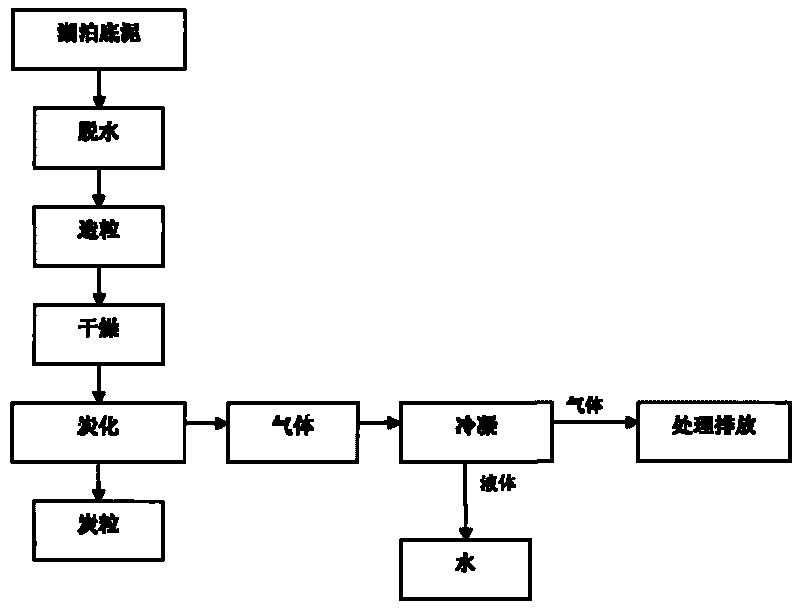

Method used

Image

Examples

Embodiment 1

[0022] Take a certain amount of Dianchi Lake sediment that has been granulated and dried, put it into the carbonization furnace, pass in water steam to displace the air in the furnace and continue to pass in the protective gas, heat up to 400°C at a heating rate of 10°C / min, and carbonize for 60 minutes. Naturally cool to room temperature. The solid charcoal grain organic matter content that makes is 31%, and pH is 7.8, and total nutrient (N+P 2 o 5 +K 2 O) 3.6%, the maximum water holding capacity (Maximum water holding capacity) is 55%, and the heavy metal content does not exceed the standard, which can obviously improve the permeability and water holding capacity of the soil, and can provide certain nutrients.

Embodiment 2

[0024] Take a certain amount of Dianchi Lake bottom sludge that has been granulated and dried, put it into the carbonization furnace, pass in steam to replace the air in the furnace and continue to pass in the protective gas, heat up to 450°C at a heating rate of 15°C / min, and carbonize for 60 minutes. Naturally cool to room temperature. The solid charcoal grain organic matter content that makes is 30.5%, and pH is 7.7, and total nutrient (N+P 2 o 5 +K 2 O) 3.6%, the maximum water retention capacity is 57%, and the heavy metal content does not exceed the standard, which can obviously improve the permeability and water retention capacity of the soil, and can provide certain nutrients.

Embodiment 3

[0026] Take a certain amount of Dianchi Lake sediment that has been granulated and dried, put it into a carbonization furnace, pass in steam to displace the air in the furnace and continue to pass in protective gas, heat up to 500°C at a heating rate of 20°C / min, and carbonize for 60 minutes. Naturally cool to room temperature. The solid charcoal particle organic matter content that makes is 29%, and pH is 7.6, and total nutrient (N+P 2 o 5 +K 2 O) 3.6%, the maximum water retention capacity is 58%, and the heavy metal content does not exceed the standard, which can obviously improve the permeability and water retention capacity of the soil, and can provide certain nutrients.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com