Preparation method of millet bran dietary fiber

A technology of dietary fiber and production method, applied in the field of grain processing, to achieve the effects of wide sources, improvement of sensory quality, change of molecular structure and palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

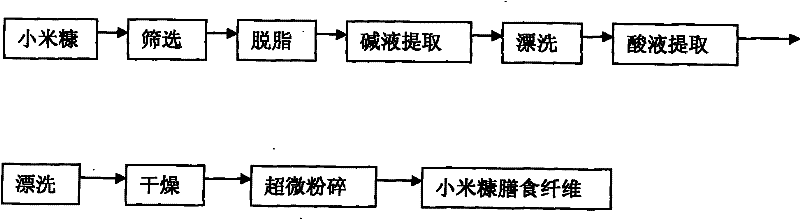

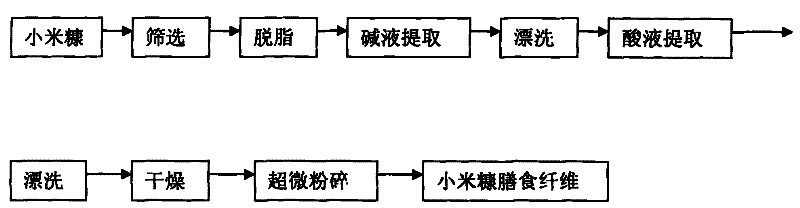

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, the making of millet bran dietary fiber

[0035] (1) Screen 100Kg of millet bran to remove impurities, transfer it to a degreasing tank, add 3L (that is: millet bran:petroleum ether=1kg:3L) of petroleum ether, soak for 24 hours, remove the petroleum ether, take it out and let it air in the air Remove residual petroleum ether.

[0036] (2) Put the degreased millet bran in the above step (1) into an extraction tank, add 500Kg of 2.5mol / L NaOH, stir and extract at 40°C for 3 hours, rinse the alkali-extracted millet bran with tap water to pH The value was 8; then drench to remove the water.

[0037] (3) Next, add 1500 Kg of 0.2 mol / L HCl to the extraction tank, stir and extract at 60° C. for 0.5 h, and wash the acid-extracted millet bran with tap water until the pH value is 6. After leaching off the water, dry the millet bran under hot air at 80° C. until the water content is 8% (mass percentage), take it out and cool it naturally to obtain the dried millet ...

Embodiment 2

[0039] Embodiment 2, the making of millet bran dietary fiber

[0040] (1) Filter 100Kg of millet bran to remove impurities, transfer it to a degreasing tank, add 5L (that is: millet bran: petroleum ether = 1kg: 5L) petroleum ether, soak for 12 hours, remove the petroleum ether, and take it out for natural ventilation Dry to remove residual petroleum ether.

[0041] (2) Transfer the degreased millet bran into an extraction tank, add 1000Kg of 1.0mol / L NaOH, stir and extract at 50°C for 1.5h, rinse the alkali-extracted millet bran with tap water until the pH value is 8; Drain off the water.

[0042] (3) Next, add 1000 Kg of 1.0 mol / L HCl to the extraction tank, stir and extract at 50° C. for 1.5 h, and wash the acid-extracted millet bran with tap water until the pH value is 7. After leaching off the water, dry the millet bran with hot air at 100° C. until the water content is 7% (mass percentage), take it out and cool it naturally to obtain the dried millet bran.

[0043] (4)...

Embodiment 3

[0044] Embodiment 3, the making of millet bran dietary fiber

[0045](1) Screen 100Kg of millet bran to remove impurities, transfer it to a degreasing tank, add 6L (that is: millet bran:petroleum ether=1kg:6L) and soak in petroleum ether for 8h, after rinsing off the petroleum ether, take it out and remove it in the air with natural ventilation residual petroleum ether.

[0046] (2) Transfer the degreased millet bran into an extraction tank, add 1500Kg of 0.5mol / L NaOH, stir and extract at 60°C for 0.5h, rinse the alkali-extracted millet bran with tap water until the pH value is 7; Drain off the water.

[0047] (3) Next, add 500 Kg of 2.5 mol / L HCl to the extraction tank, stir and extract at 40°C for 3 hours, and wash the acid-extracted millet bran with tap water until the pH value is 7. After leaching off the water, dry the millet bran under hot air at 120° C. until the water content is 6% (mass percentage), take it out and cool it naturally to obtain the dried millet bran....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com