Low-temperature liquid phase synthesizing method of monodisperse square crystalline phase ferrous selenide square nanometer sheet

A synthesis method and tetragonal crystal phase technology, applied in the field of iron selenide, can solve the problems of unfavorable in-depth research, highly toxic iron pentacarbonyl, expensive reagents, etc., and achieve the effect of controllable particle size and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

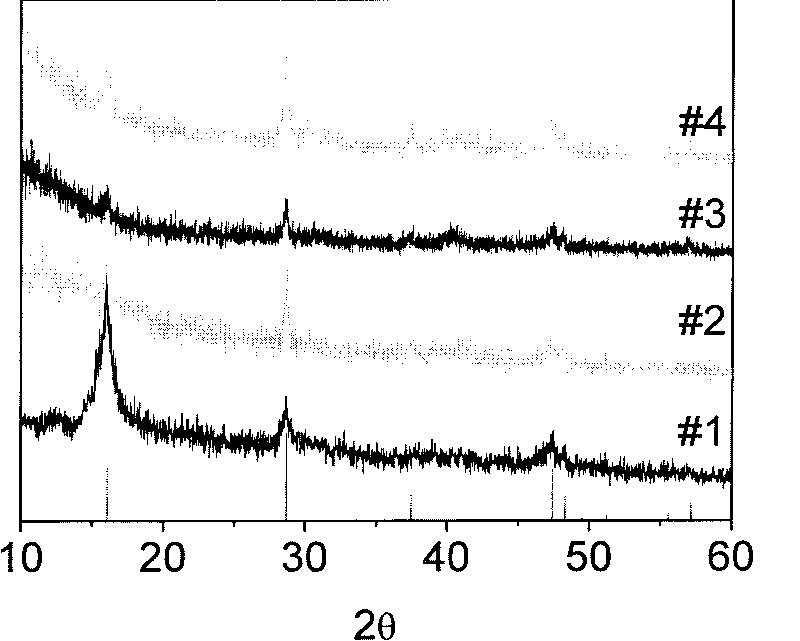

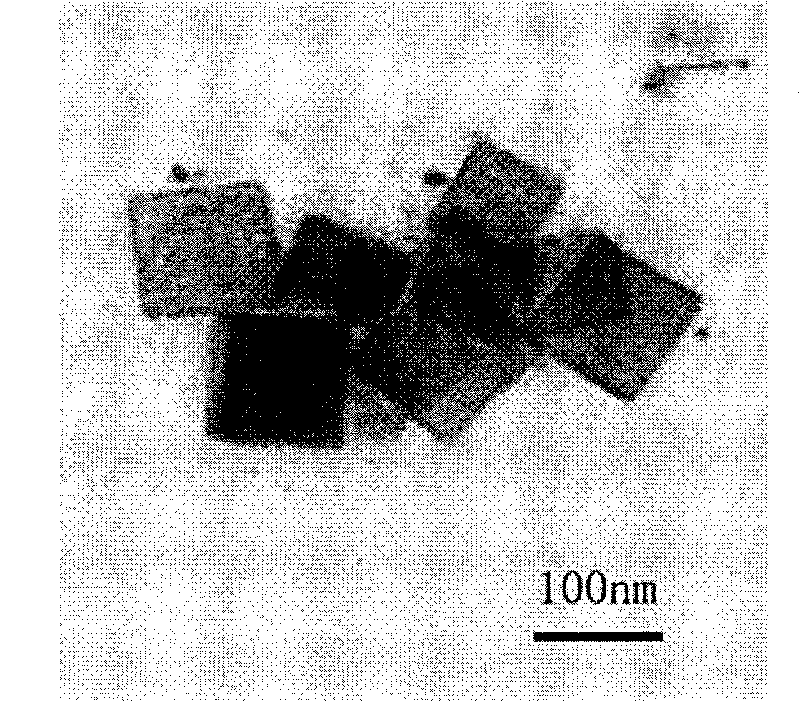

[0020] 0.04M anhydrous ferrous chloride (FeCl 2 ) of oleylamine solution 7.5ml into the three-necked flask, high-purity argon (99.99%) protected heating to 110 ° C until the solid is completely dissolved to obtain a mixed solution; after 0.5ml oleic acid is injected into the flask, Add the prepared selenium-trioctylphosphorus (Se-TOP) at a ratio of 1:1. Se-TOP refers to dissolving Se powder in trioctylphosphorus. In experiments, it is usually prepared as a 1M solution, because selenium is solid, it is usually dissolved in trioctylphosphine. Set the reaction temperature to 320° C., and react for 20 minutes; monodisperse tetragonal iron selenide nanosheets are prepared. The XRD diffraction peaks of the product are as figure 1 As shown in curve 1; the shape is as figure 2 shown. Such as figure 1 As shown in the middle curve 1, all the diffraction peaks can correspond to the standard peak of tetragonal β-FeSe at the bottom (JCPDS No.85-0735), which shows that the obtained pr...

Embodiment 2

[0022] 0.04M anhydrous FeCl 2 Add 7.5ml of oleylamine solution of tetradecyl glycol and 0.4M into a three-necked flask, and heat it to 140°C under the protection of high-purity argon (99.99%) until the solid is completely dissolved to obtain a mixed solution; 0.5ml of oleic acid is injected After arriving in the three-necked flask, add selenium-trioctylphosphorus (Se-TOP) prepared according to the molar ratio of iron ion and selenium 1:1, set the reaction temperature at 330°C, and react for 15 minutes; monodisperse tetragonal crystals are obtained phase iron selenide nanosheets. The XRD diffraction peaks of the product are as figure 1 As shown in #2, all the diffraction peaks can correspond to the standard peak of tetragonal β-FeSe at the bottom (JCPDS No.85-0735), so it can be known that the obtained product is a pure tetragonal β-FeSe structure.

Embodiment 3

[0024] 0.025M anhydrous FeCl 2 Ferrous chloride and 7.5 ml of oleylamine solution of tetradecyl glycol of 0.2M were mixed and added into a three-necked flask, protected and heated to 130° C. until the solid was completely dissolved under high-purity argon (99.99%) to obtain a mixed solution; After 0.3ml of oleic acid was injected into the flask, the prepared selenium-trioctylphosphorus (Se-TOP) was added according to the molar ratio of iron ion and selenium 1:1, the reaction temperature was set to 300°C, and the reaction was carried out for 5 minutes; Dispersed tetragonal iron selenide nanosheets. The XRD diffraction peaks of the product are as figure 1 As shown in #3, all the diffraction peaks correspond to the standard peaks of the tetragonal β-FeSe at the bottom (JCPDS No.85-0735), which shows that the obtained product is a pure tetragonal β-FeSe structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com