Method for laminating on surface of cement-based material by using sodium alginate-supported bacterial strain

A technology of cement-based materials and sodium alginate, which is applied in the field of solidification, can solve the problems of insufficient strength and pollution, and achieve the effects of low cost, excellent performance, and improved impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

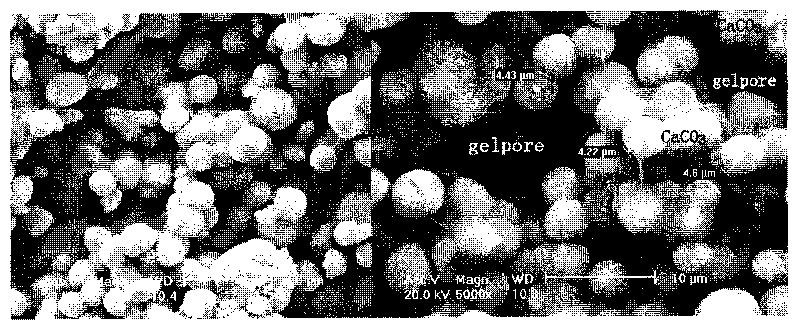

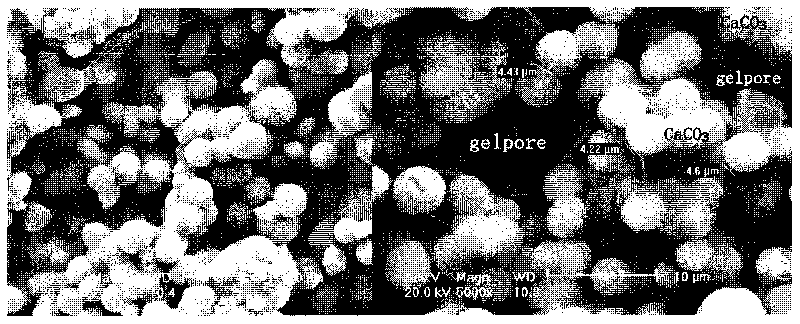

Image

Examples

Embodiment 1

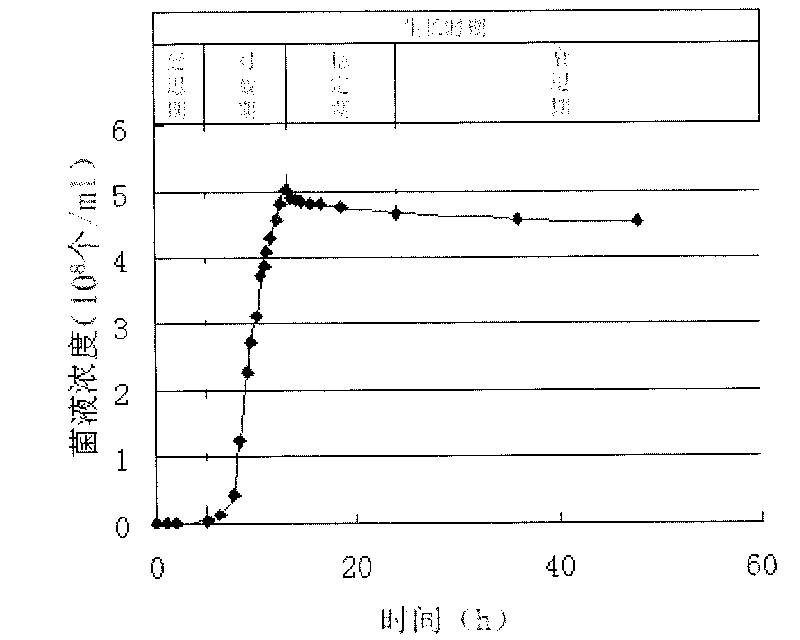

[0028] Inoculate the strain Bacillus pasteurii into the Erlenmeyer flask containing the culture medium: the composition of the culture medium is shown in Table 1, shake culture in a constant temperature shaking incubator at 25-37°C, control the initial pH condition at 6.0-8.0, and cultivate for 24-36 The strains that had grown to the stationary phase were taken out within hours. Centrifuge the obtained bacterial liquid with a certain concentration at 5000rpm for 6min, and wash out the centrifuged bacterial cells with 200-500μl trace of newly prepared culture medium to obtain a concentration of 1.0×10 9 ~1.0×10 10 cell / mL highly concentrated bacterial solution, use a paintbrush (0.8-1cm wide) to gently smear the bacterial solution on the surface of a 3cm×3cm×3cm cement stone substrate, wait for the surface to dry, and then use another paintbrush to paint the sodium alginate The mass volume concentration of the viscous solution is 10g / L and spread on the surface of the substrat...

Embodiment 2

[0034] The strain Bacillus pasteurii was inoculated into a Erlenmeyer flask containing medium (the medium composition is shown in Table 2), and cultured in a constant temperature shaking incubator at 25-37°C, with the initial pH controlled at 6.0-8.0, and cultured for 24-37°C. 36 hours to remove. The next steps are the same as those in Example 1. The resulting treated cement stone will be removed from the composite film to measure its capillary water absorption coefficient K is 0.0004 ~ 0.0008g.cm -2 .s -1 / 2 .

[0035] Medium composition used in the embodiment 2 of table 2

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com