Optical resonance composite material in noble metal/titanium dioxide micro-nano structure

A technology of micro-nano structure, titanium dioxide, applied in other chemical processes, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

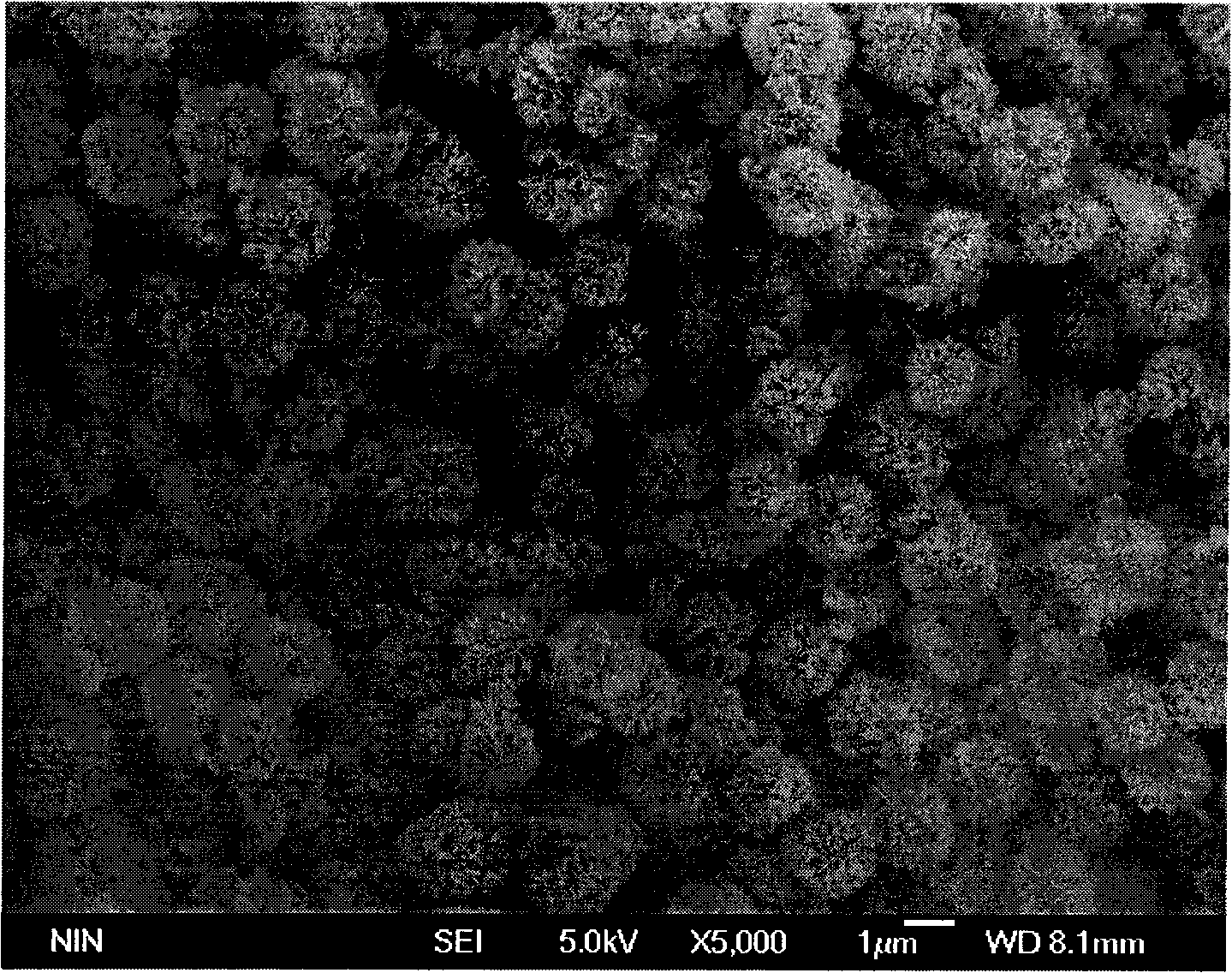

Embodiment 1

[0020] Titanium tetrachloride was added dropwise to deionized water under ice bath conditions to prepare a titanium tetrachloride aqueous solution with a mass fraction of 50 wt%, and the aqueous solution was refrigerated in a refrigerator for subsequent use; 0.2 g of silver nitrate was dissolved in 1 ml of deionized water Prepared into silver nitrate aqueous solution. First, 4 grams of n-butyl titanate was added to 30 ml of toluene, and stirred in an ice bath for 0.5 hours; then all the prepared silver nitrate aqueous solution was added to the toluene aqueous solution of n-butyl titanate and stirred for 0.5 hours; then Add 4ml of titanium tetrachloride aqueous solution with a mass fraction of 50wt%, and magnetically stir for 1 hour; finally move the mixed system into a stainless steel autoclave lined with polytetrafluoroethylene, wherein the volume of the reactant is about 80% of the volume of the autoclave. %, put the reactor into a constant temperature drying oven and react ...

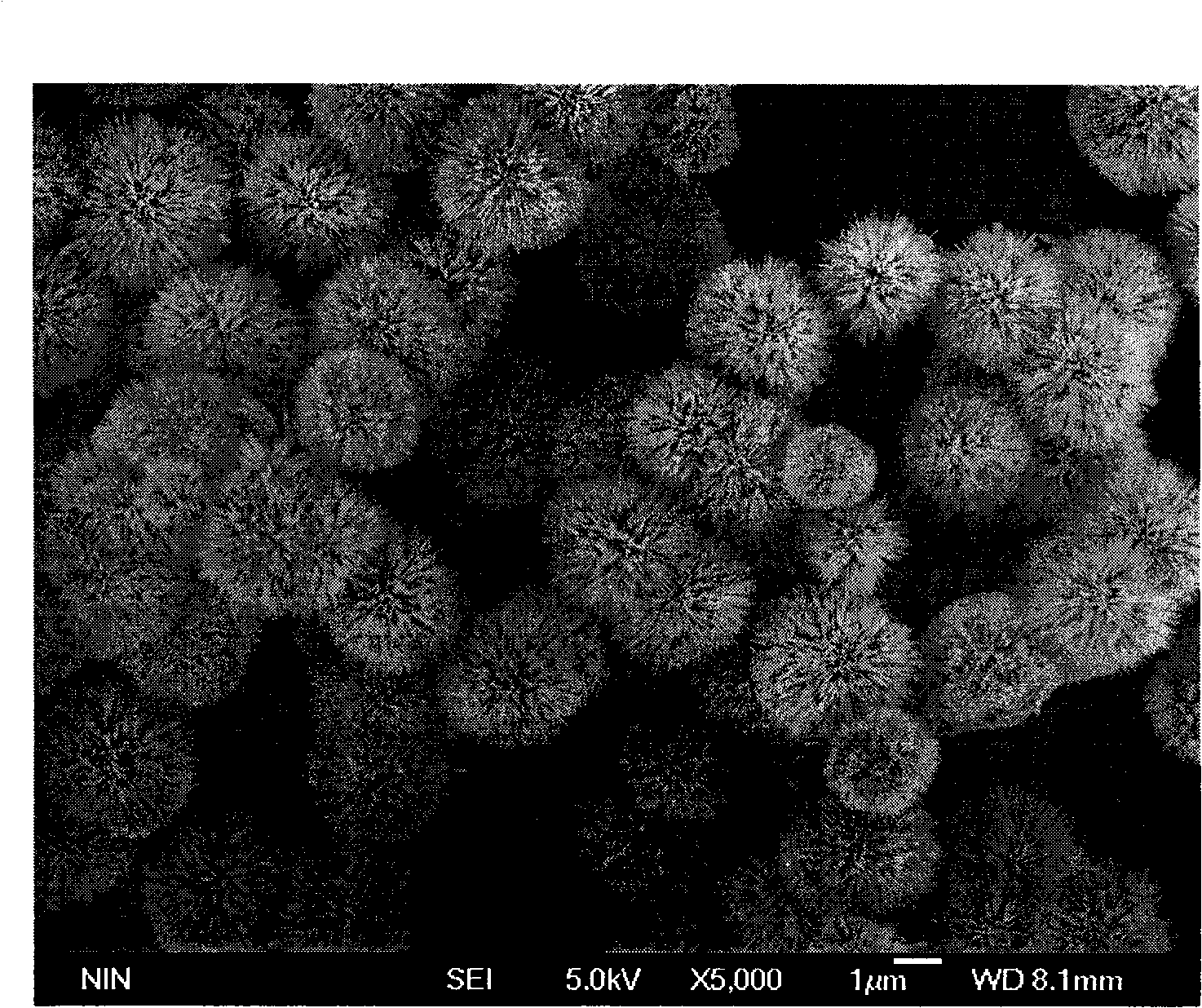

Embodiment 2

[0022] Titanium tetrachloride was added dropwise to deionized water under ice bath conditions to prepare a titanium tetrachloride aqueous solution with a mass fraction of 50 wt%, and the aqueous solution was refrigerated in a refrigerator for subsequent use; 0.5 g of silver nitrate was dissolved in 1 ml of deionized water Prepared into silver nitrate aqueous solution. First, 4 grams of n-butyl titanate was added to 30 ml of toluene, and stirred in an ice bath for 0.5 hours; then all the prepared silver nitrate aqueous solution was added to the toluene aqueous solution of n-butyl titanate and stirred for 0.5 hours; then Add 4ml of titanium tetrachloride aqueous solution with a mass fraction of 50wt%, and magnetically stir for 1 hour; finally move the mixed system into a stainless steel autoclave lined with polytetrafluoroethylene, wherein the volume of the reactant is about 80% of the volume of the autoclave. %, put the reactor into a constant temperature drying oven and react ...

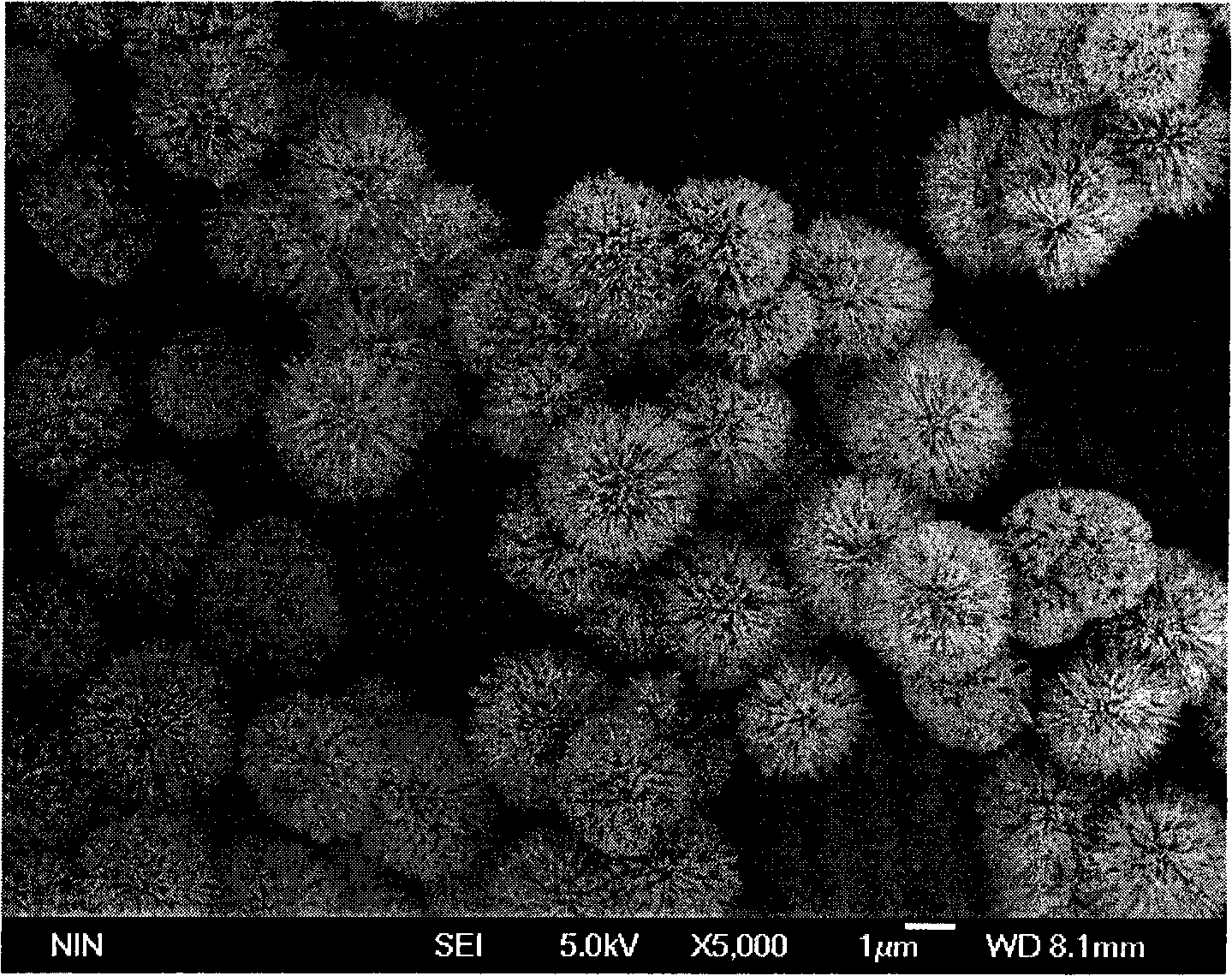

Embodiment 3

[0024] Titanium tetrachloride was added dropwise to deionized water under ice bath conditions to prepare a titanium tetrachloride aqueous solution with a mass fraction of 50 wt%, and the aqueous solution was refrigerated in a refrigerator for subsequent use; 1.0 g of silver nitrate was dissolved in 1 ml of deionized water Prepared into silver nitrate aqueous solution. First, 4 grams of n-butyl titanate was added to 30 ml of toluene, and stirred in an ice bath for 0.5 hours; then all the prepared silver nitrate aqueous solution was added to the toluene aqueous solution of n-butyl titanate and stirred for 0.5 hours; then Add 4ml of titanium tetrachloride aqueous solution with a mass fraction of 50wt%, and magnetically stir for 1 hour; finally move the mixed system into a stainless steel autoclave lined with polytetrafluoroethylene, wherein the volume of the reactant is about 80% of the volume of the autoclave. %, put the reactor into a constant temperature drying oven and react ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com