Halogenohydrin dehalogenase mutant strain, halogenohydrin dehalogenase mutant and preparation method and application thereof

A technology of halohydrin dehalogenase and mutant, applied in the field of microorganisms, can solve the problem of not finding industrialized production of halohydrin dehalogenase and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

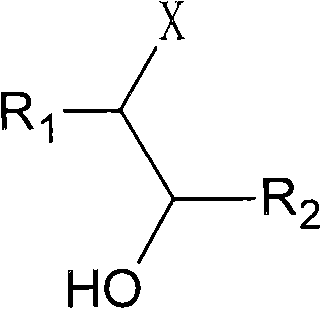

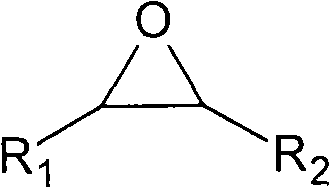

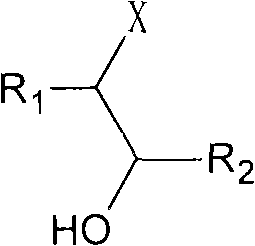

Method used

Image

Examples

preparation example Construction

[0027] The method for preparing a halohydrin dehalogenase mutant according to one embodiment of the present invention comprises the following steps:

[0028] A) carrying out shake flask fermentation according to the strain of the embodiment of the present invention;

[0029] B) seed tank fermentation;

[0030] C) commercial tank fermentation; and

[0031] D) Treating the bacterial cells obtained from commercial tank fermentation to obtain liquid halohydrin dehalogenase mutants.

[0032] The method for preparing a halohydrin dehalogenase mutant according to an embodiment of the present invention may further include:

[0033] E) drying the obtained liquid halohydrin dehalogenase mutant to obtain a solid halohydrin dehalogenase mutant.

[0034] Each step of the present invention is described in detail below.

[0035] 1. Construction process of genetically engineered bacteria:

[0036] 1. Extraction of Agrobacterium radiobacter AD1 genomic DNA:

[0037] 1) 5ml LB culture med...

Embodiment

[0132] I. the construction of genetically engineered bacteria of the present invention

[0133] Relying on large primer PCR technology, mutate the halide ion binding region (Pro175-Tyr187) of halohydrin dehalogenase, construct the mutant and vector pBAD, transform into the host MC1061 to construct a mutant library, and screen the mutant library , found that the effect of P175H and Y177W mutations is relatively ideal, the amino acid sequence of the mutant is SEQID NO.2, and a genetically engineered bacterium capable of producing the mutant was further obtained, and the preservation number of the genetically engineered bacterium is CCTCC NO: M208089.

[0134] II. Fermentation of genetically engineered bacteria

[0135] The bacterial strain of the present invention is fermented according to the following conditions.

[0136] A) Shake flask fermentation: take 5g yeast extract, 10g peptone, 10gNaCl, dissolve in 800ml distilled water, adjust the pH to 7, use distilled water to set ...

example 1

[0151] Example 1: Catalytic synthesis of (R)-4-cyano-3-hydroxybutyric acid ethyl ester

[0152] The reaction buffer (50mM Tris·H 2 SO 4 , pH: 8) heated to a constant temperature of 30°C; the substrate [(S)-4-chloro-3-hydroxybutyric acid ethyl ester] was added to the reaction buffer, and the content of the substrate in the aqueous solution was controlled to be 10g / l, Stir well. First dilute the 30% NaCN solution by 10-20 times, then adjust the pH of the NaCN solution to 8.0 with dilute sulfuric acid, add the diluted NaCN according to the molar ratio of the substrate and NaCN in a ratio of 1:2, and stir evenly; add the haloalcohol for dehalogenation The enzyme mutant (halohydrin dehalogenase mutant: (S)-4-chloro-3-hydroxybutyrate ethyl ester = 1:100 (w / w)) catalyzes the reaction, and the reaction is regulated by adding NaCN during the reaction Liquid pH. After reacting at 30°C for 24 hours, the catalytic efficiency reaches 97%, and the optical purity (ee) value of the target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com