Energy-saving ceramic tunnel kiln

A tunnel kiln and energy-saving technology, which is applied in the field of ceramic kilns, can solve the problems of uneven temperature in the firing zone section, prolong the firing time, and affect the combustion efficiency, so as to improve product quality and save electricity, temperature stability, and energy saving. fuel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

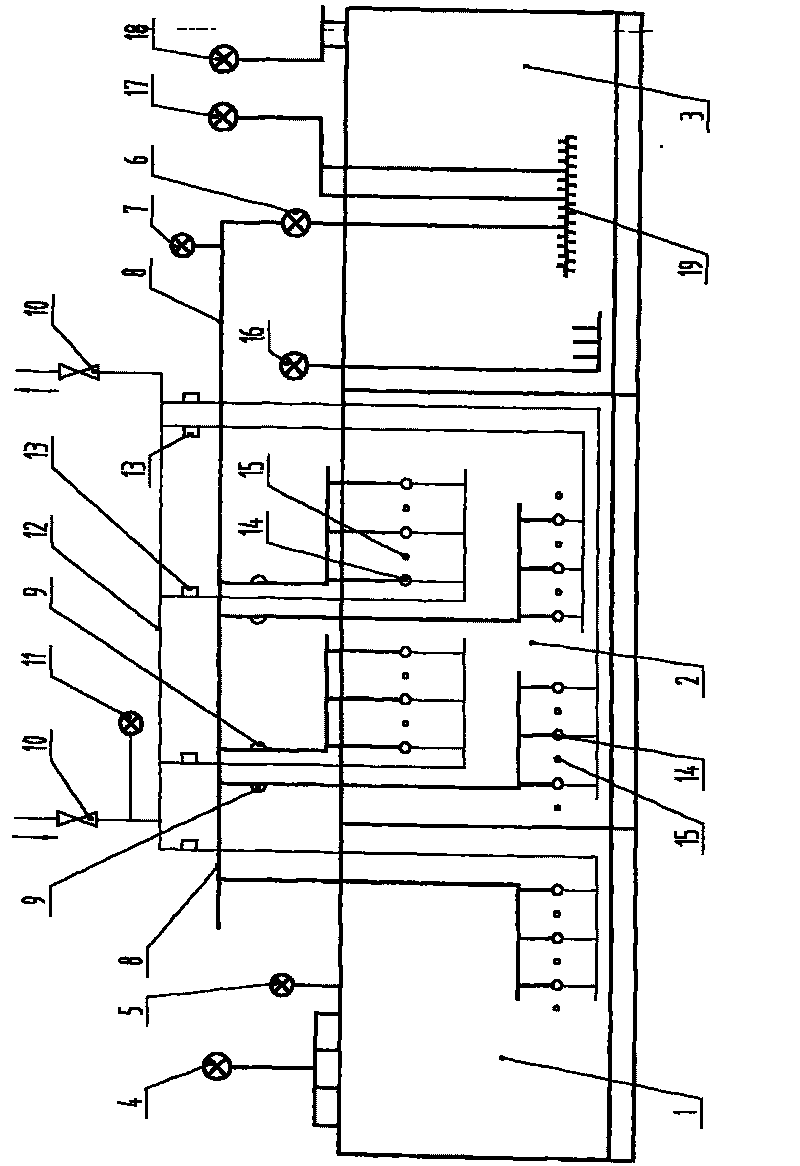

[0025] Hereinafter, a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

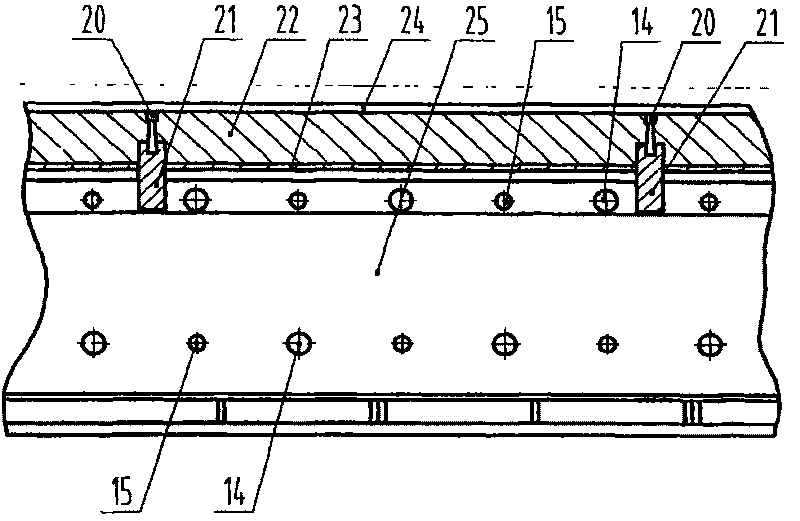

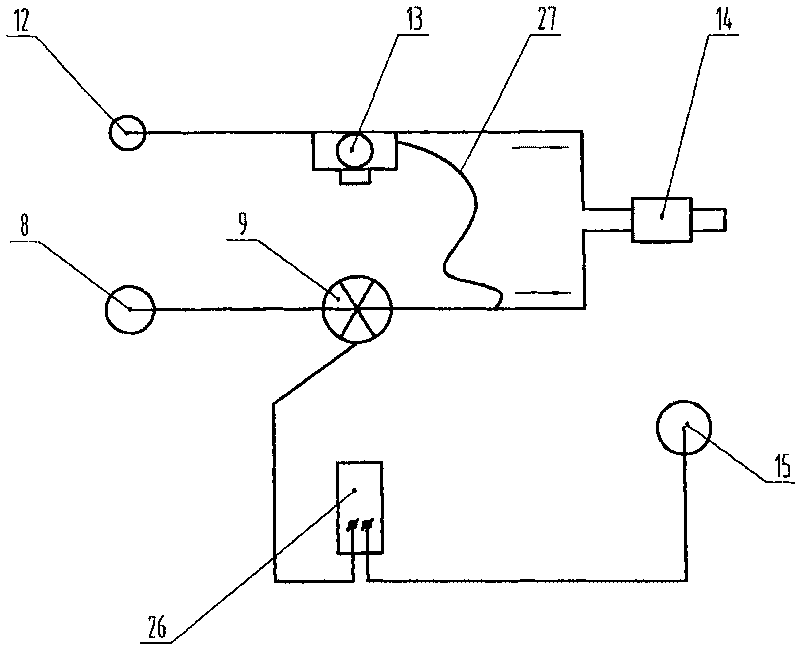

[0026] Such as figure 1 and figure 2 As shown, the energy-saving tunnel kiln of the present invention is composed of a kiln body, a combustion system, a fan system and the like. The kiln body is 80 meters long and has a preheating zone 1, a firing zone 2 and a cooling zone 3. The preheating zone 1, firing zone 2 and cooling zone 3 are all provided with kiln passages 25. The firing zone 2 is vertically provided with two firewalls 21 at both ends of the 1300-1380°C high temperature zone to separate the upper part of the high temperature zone from the upper parts of other temperature zones. The fire-retaining wall 21 is a cuboid, made of light mullite bricks, and the hanger 20 made of stainless steel is fixed on the kiln roof 24; the width of the wall is the same as that of the passage 25 in the kiln, and the thickness is 23cm. The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com