Refractory material slag resistance test device

A technology of refractory materials and experimental devices, applied in measuring devices, analytical materials, weather resistance/light resistance/corrosion resistance, etc., can solve problems such as relative rotation without consideration, achieve high degree of automation, accurate temperature control, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

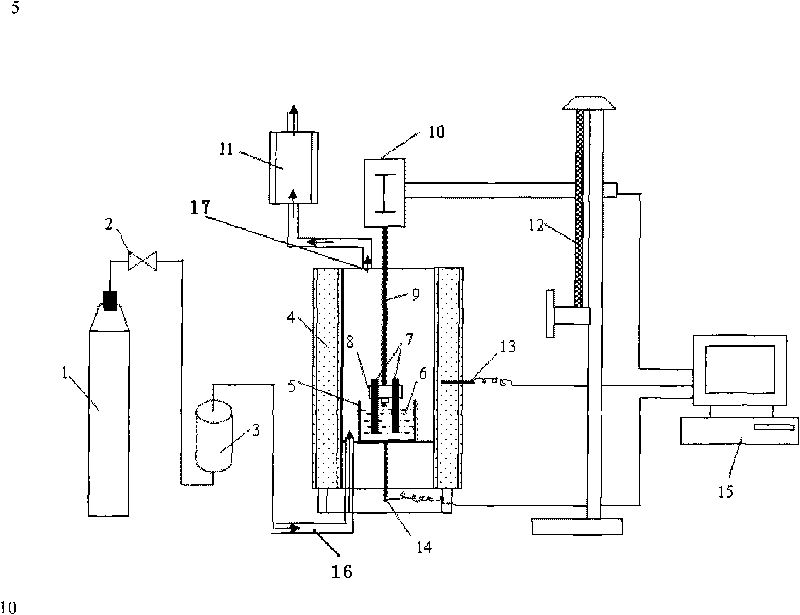

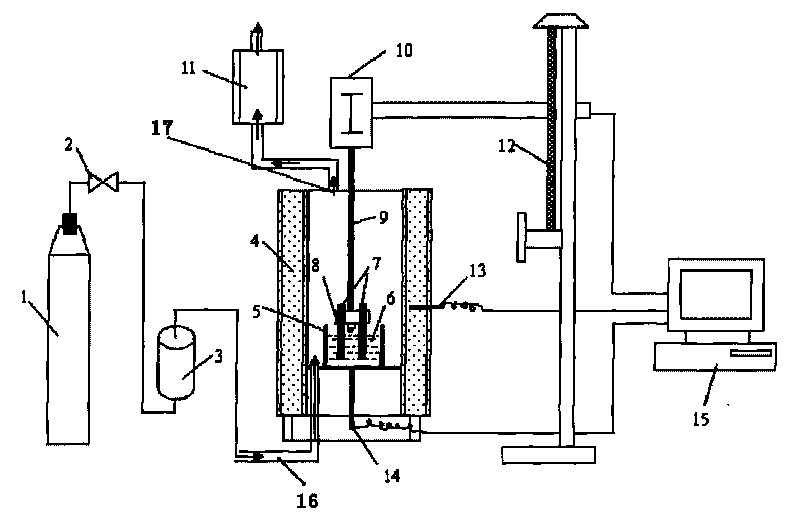

[0013] Such as figure 1 As shown, the heating furnace 4 used in the experiment is a molybdenum wire furnace, the refractory material used in the experiment is a blast furnace refractory material, and the slag 6 is taken from the blast furnace site. Cut the refractory material to a certain size according to the experimental requirements, fix the prepared refractory material sample 7 on the disc-shaped sample tray 8, put the blast furnace slag 6 in the crucible 5, and then place the crucible 5 in the furnace, And turn on the computer 15, open the temperature rise program, control the temperature rise of the heating furnace body through the temperature control thermocouple 13, open the gas valve 2 at the same time, the protective gas enters the furnace from the bottom of the furnace through the gas valve and the gas purification device from the gas cylinder, and passes through the temperature measurement thermoelectric The couple 14 monitors the temperature in the furnace in real...

Embodiment 2

[0015] The operation steps are the same as in Example 1, wherein the refractory sample is a refractory material for steelmaking electric furnace, and the slag is steelmaking slag.

Embodiment 3

[0017] The operation steps are the same as in Example 1, wherein the refractory material is high-alumina refractory material for torpedo tank cars, and the slag is blast furnace slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com