Toner, developer, toner cartridge, process cartridge, and image forming apparatus

A toner and solvent technology, applied in the field of electrostatic latent image development toners, can solve the problems of poor high temperature storage, poor toner blocking resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0163] Examples of catalysts that can be used in the production of crystalline polyester resins include compounds of alkali metals such as sodium or lithium; compounds of alkaline earth metals such as magnesium or calcium; metals such as zinc, manganese, antimony, titanium, tin, zirconium, or germanium compounds; phosphite compounds; phosphate compounds; and amine compounds. Specific examples thereof include sodium acetate, sodium carbonate, lithium acetate, lithium carbonate, calcium acetate, calcium stearate, magnesium acetate, zinc acetate, zinc stearate, zinc naphthenate, zinc chloride, manganese acetate, naphthenic acid Manganese, titanium tetraethoxide, titanium tetrapropoxide, titanium tetraisopropyloxide, titanium tetrabutyloxide, antimony trioxide, triphenylantimony, tributylantimony, tin formate, tin oxalate, tetraphenyl Tin, dibutyltin dichloride, dibutyltin oxide, diphenyltin oxide, zirconium tetrabutoxide, zirconium naphthenate, zirconyl carbonate, zirconyl acetat...

Embodiment 1

[0366] Production of toner particles (1)

[0367] Charge the following ingredients into a 3 L reaction vessel equipped with a thermometer, pH meter and stirrer:

[0368] Ion exchanged water: 400 parts

[0369] Crystalline polyester resin dispersion (1) (20% concentration of crystalline polyester resin): 50 parts

[0370] Non-crystalline polyester resin dispersion (1) (concentration containing non-crystalline polyester resin is 20%): 250 parts

[0371] Anionic surfactant (trade name: NEOGEN RK, manufactured by Dai-ichi Kogyo Seiyaku Co., Ltd., active ingredient content 60%): 2.5 parts

[0372] While stirring the contents of the reaction vessel at 150 rpm and adjusting the temperature from the outside using a mantle heater, the contents were maintained at 30° C. for 30 minutes.

[0373] Afterwards, add the following ingredients to it:

[0374] Colorant dispersion (1) (15% colorant concentration): 47 parts

[0375] Release agent dispersion (release agent concentration is 25%...

Embodiment 2

[0388] Preparation of Toner Particles (2)

[0389] Toner particles (2) were prepared in the same manner as the preparation of toner particles (1) in Example 1, except that the crystalline polyester resin dispersion (2) and the non-crystalline polyester resin dispersion were used. Liquid (2) was used instead of the crystalline polyester resin dispersion liquid (1) and the non-crystalline polyester resin dispersion liquid (1) in Example 1, respectively.

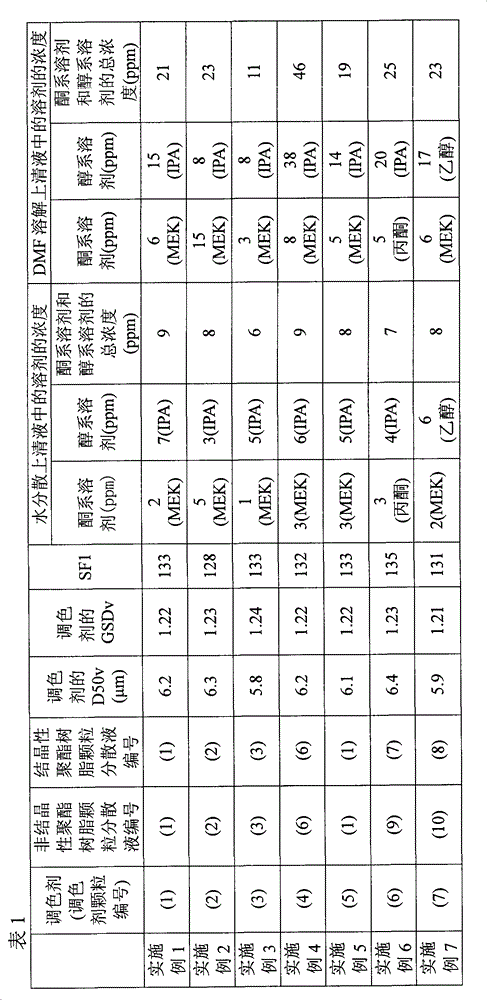

[0390] The obtained toner particles (2) had a volume average particle diameter (D50) of 6.3 μm, a GSD (volume) of 1.23, and a shape factor SF1 determined by observing the particle shape under LUZEX FT (trade name, manufactured by Nireco Corporation) for 128. When the water-dispersed supernatant of the toner was prepared as described above, the concentration of methyl ethyl ketone in the water-dispersed supernatant measured by the above method was 5 ppm, and the concentration of methyl ethyl ketone in the water-dispersed supern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com