SCR ESD protective structure with high maintaining voltage

A high maintenance voltage, electrostatic discharge protection technology, applied in emergency protection circuit devices, emergency protection circuit devices, circuits, etc. for limiting overcurrent/overvoltage, which can solve the problem of increasing device size and reducing secondary thermal shock Through the failure current, increase the maintenance voltage and other problems, to achieve the effect of eliminating the latch-up effect and good ESD protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

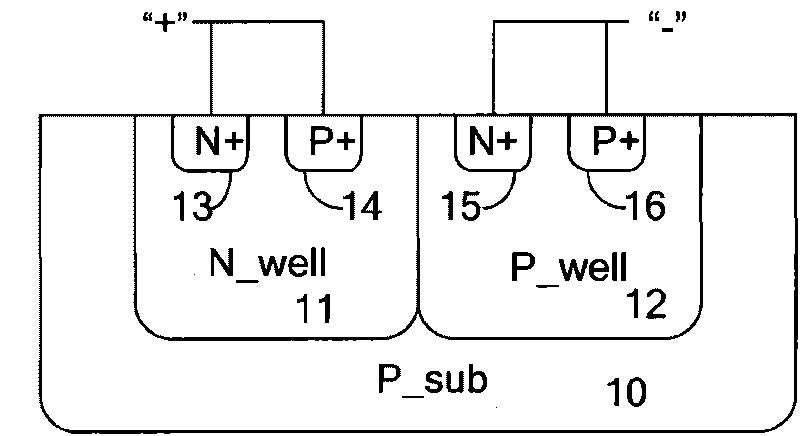

[0022] figure 1 It is a schematic cross-sectional view of a traditional lateral SCR. This is a double-well device manufactured on a P-type substrate 10. On the substrate 10 are an N-type well 11 and a P-type well 12. The N-type well 11 is connected to the P+ doped region 14 through an N+ doped region 13. , as the anode of the SCR, the P-type well 12 is connected to the P+ doped region 16 through the N+ doped region 15, and serves as the cathode of the SCR; the P+ doped region 14, the N-type well 11, the P-type well 12, and the N+ doped region Region 15 constitutes the structure of the PNPN.

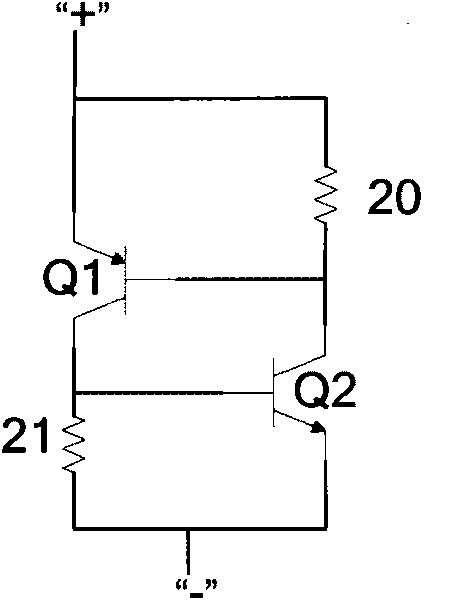

[0023] figure 2 yes figure 1 The equivalent circuit diagram of the structure shown includes a parasitic PNP transistor Q1 and a parasitic NPN transistor Q2, N well resistor 20 and P well resistor 21.

[0024] In a traditional CMOS process, both the PNP transistor Q1 and the NPN transistor Q2 are parasitic devices, and the emitter, collector, and base of the parasitic PNP transistor Q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com