Process method for simultaneously extracting soybean function factor and therapeutic factor from bean pulp

A process method and soybean meal technology are applied in the field of deep processing of soybean by-products, which can solve the problem of not extracting the process method, and achieve the effects of low cost, improved utilization value and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

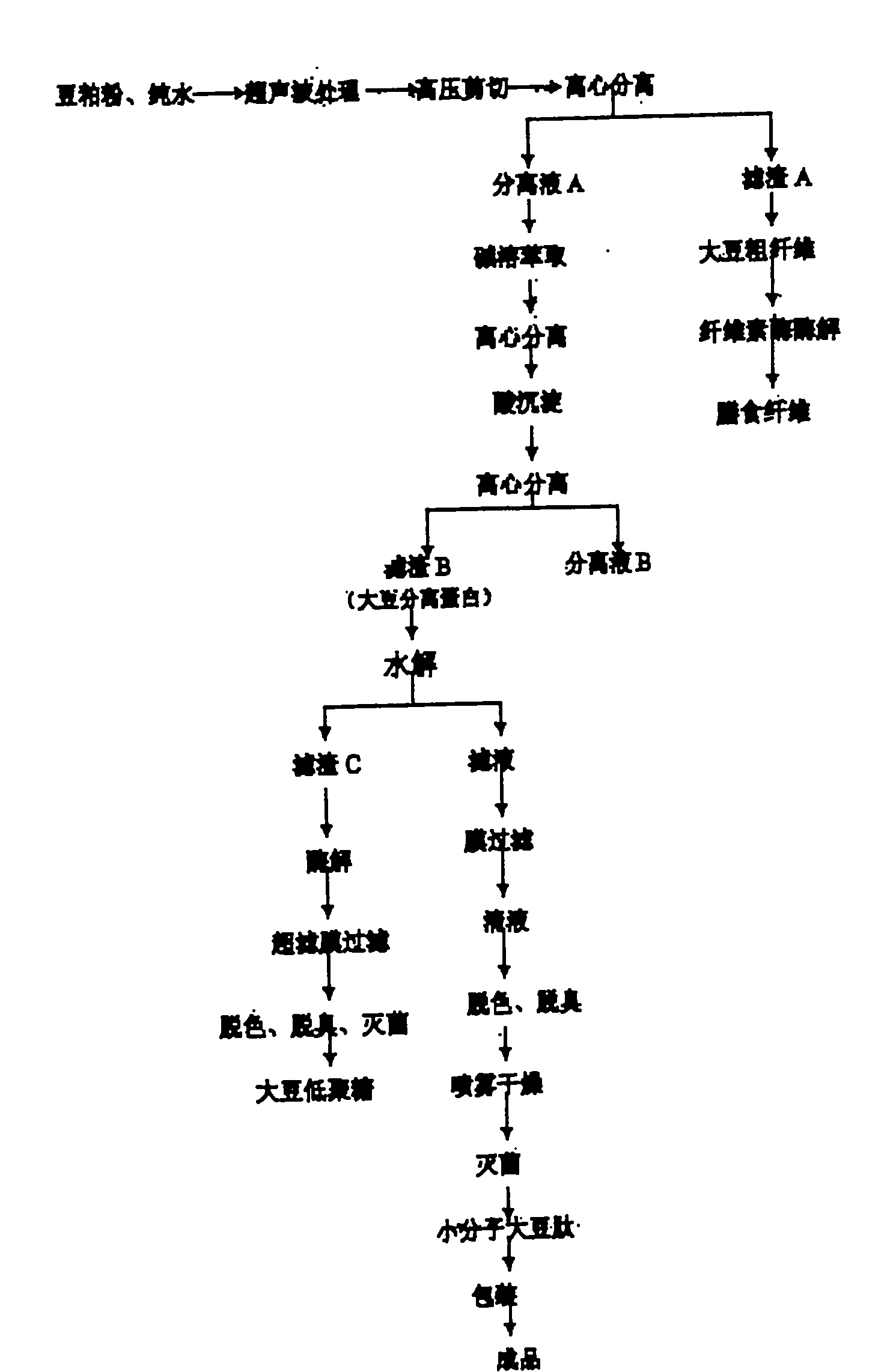

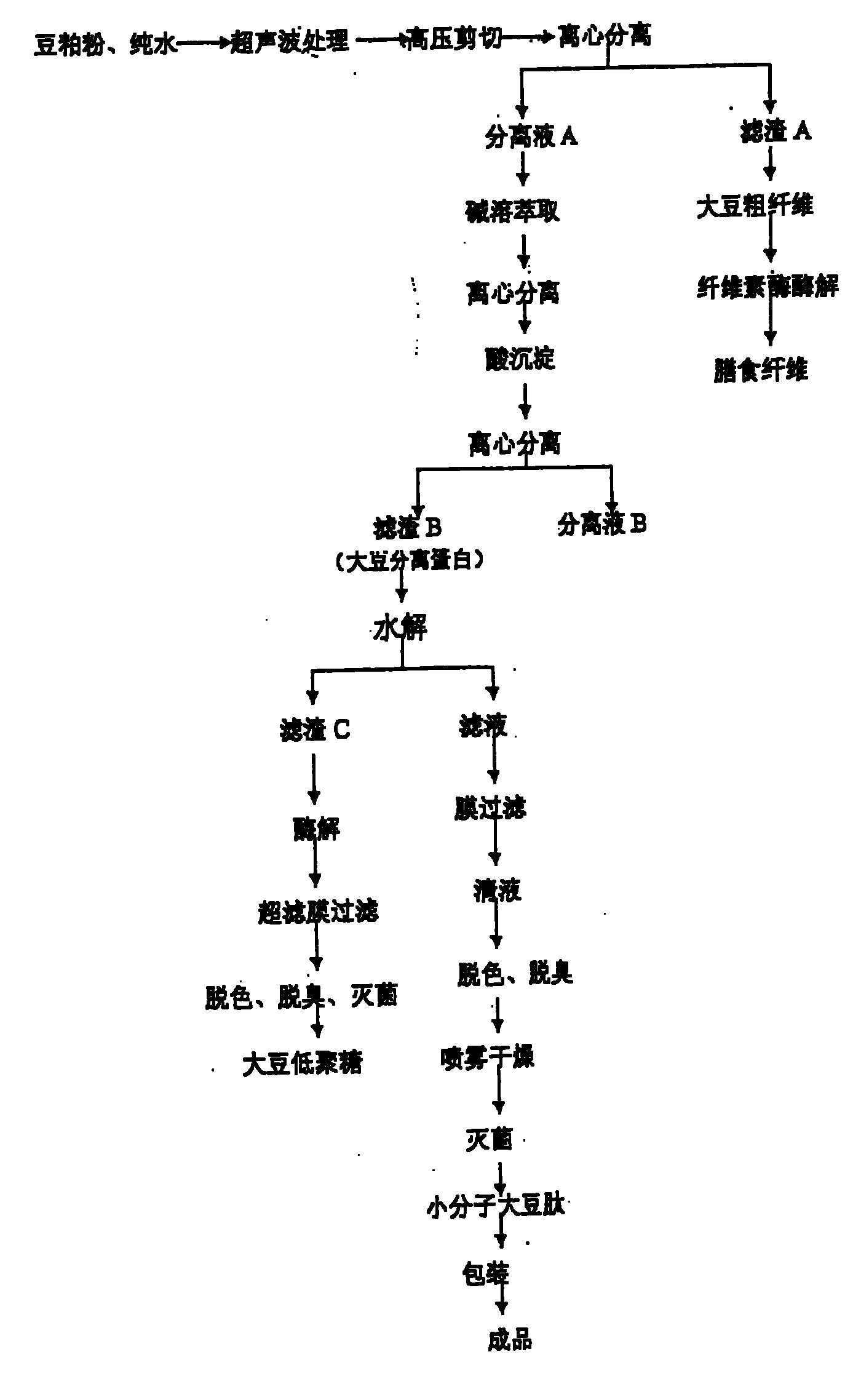

Image

Examples

Embodiment Construction

[0016] As shown in the figure: a process for simultaneously extracting soybean function and therapeutic factors from soybean meal, including the following steps:

[0017] 1. The high-temperature or low-temperature soybean meal is sequentially subjected to ultrasonic treatment, high-pressure shearing and centrifugation to obtain the separation liquid A and filter residue A respectively, and the separation liquid A is sequentially subjected to alkali-solution extraction, centrifugation, protein precipitation and re-centrifugation to retain Precipitate and finally dry to obtain soybean protein isolate. Soybean dietary fiber was obtained by enzymatic hydrolysis of filter residue. Among them, NaOH solution is used for alkali-solution extraction, and the extraction process conditions are: the substrate concentration is 5%, the NaOH solution is 0.1%, the extraction temperature is 50° C., and the extraction time is 1 h. The technological conditions for obtaining soybean dietary fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com