Polyacrylonitrile-based hollow carbon fiber precursor and preparation method thereof

A polyacrylonitrile-based, carbon fiber precursor technology, applied in the direction of hollow filament manufacturing, rayon manufacturing, fiber chemical characteristics, etc., can solve the problem of limiting the output of hollow carbon fiber precursor and hollow carbon fiber, not being able to spin bundles, and not suitable Carbon fiber and other problems, to achieve the effect of large hollowness, good stability and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A. According to the mass ratio of 98.8% acrylonitrile and 1.2% itaconic acid, put comonomer into the polymer kettle, then add solvent dimethyl sulfoxide (DMSO), control the mass concentration of monomer acrylonitrile in the polymerization system 22%, add initiator azobisisobutyronitrile (AIBN), the molar ratio of it and itaconic acid is 0.25: 99.75, react at a temperature of 60 ℃ for 24 hours, the polymer obtained is through de-monolysis and degassing, Made into spinning solution.

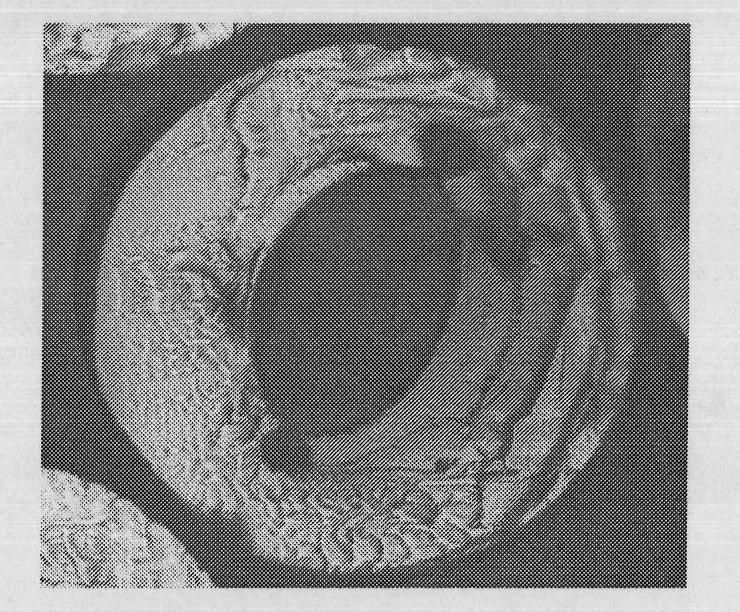

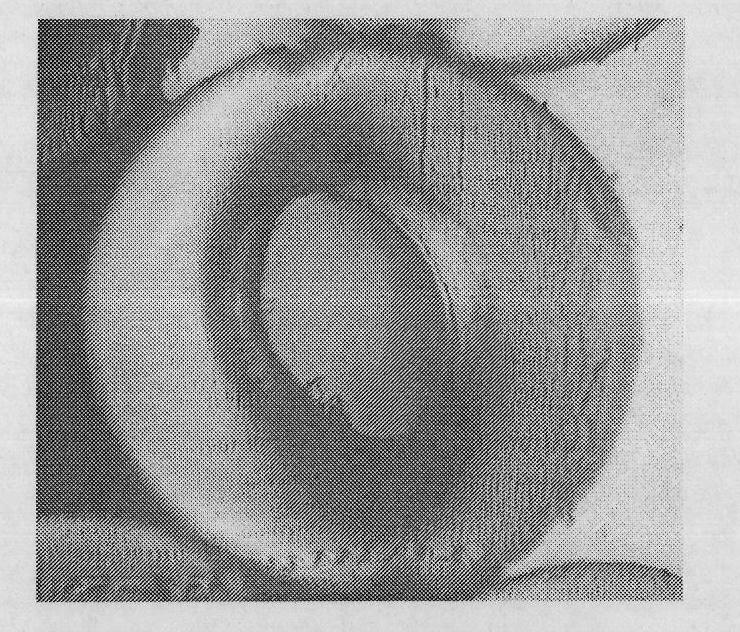

[0042] B. Conventionally extrude the spinning solution at 60°C±2°C, pass through a candle-shaped filter, and pass through a double C-shaped circular arc slit spinneret (the outer diameter of the spinneret hole is 480 μm, and the inner diameter of the spinneret hole is 320 μm) , the width at the center of the slit gap is the same as the width of the slit, and the number of holes is 94), the primary fiber is sprayed out, the coagulation draft is controlled at 0.7 times, and it is solidified in...

Embodiment 2

[0047] A, by mass ratio 94.3% acrylonitrile, 3.2% methyl acrylate and 2.5% itaconic acid, drop into comonomer in polymer still, add solvent dimethyl sulfoxide (DMSO) again, control monomer acrylonitrile The mass concentration of the polymerization system is 22%, adding the initiator azobisisobutyronitrile (AIBN), the molar ratio of it and itaconic acid is 0.25: 99.75, reacting at a temperature of 60° C. for 24 hours, and the polymer obtained by Single-degassing and degassing to make spinning solution.

[0048] B. The spinning solution is routinely extruded at 60°C ± 2°C, through a candle filter, from the double C-shaped circular arc slit spinneret (same as described in Example 1), the as-spun fibers are ejected and solidified The stretching is controlled at 0.8 times, and it enters into a coagulation bath with a temperature of 30°C±2°C for coagulation and molding, and the coagulation bath is the same as in Example 1.

[0049] C. According to step C of Example 1, polyacrylonit...

Embodiment 3

[0053] A, spinning solution preparation is the same as embodiment 1.

[0054] B. Conventionally extrude the spinning solution at 60°C±2°C, pass through a candle-shaped filter, and pass through a single C-shaped circular arc slit spinneret (the outer diameter of the spinneret hole is 480 μm, and the inner diameter of the spinneret hole is 320 μm) , the width at the center of the slit gap is the same as the width of the slit, and the number of holes is 94.), the primary fiber is sprayed out, the coagulation draft is controlled at 0.8 times, and it is coagulated into a coagulation bath with a temperature of 25 ° C ± 2 ° C. The coagulation bath is the same as Example 1.

[0055] C. After pre-drawing with hot water at 100°C, washing with water, drying, and then drawing with water vapor at 120°C, the total drafting of the two times is controlled at 12 times, and the polyacrylonitrile-based hollow carbon fiber precursor is obtained through heat setting.

[0056] The obtained hollow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com