Liquid cosmetic preparation

A cosmetic and liquid technology, applied in the direction of cosmetics, cosmetic preparations, dressing preparations, etc., can solve problems such as difficulty in ensuring stability and reduced stability, and achieve excellent storage stability and high emollient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10 and comparative example 1~5

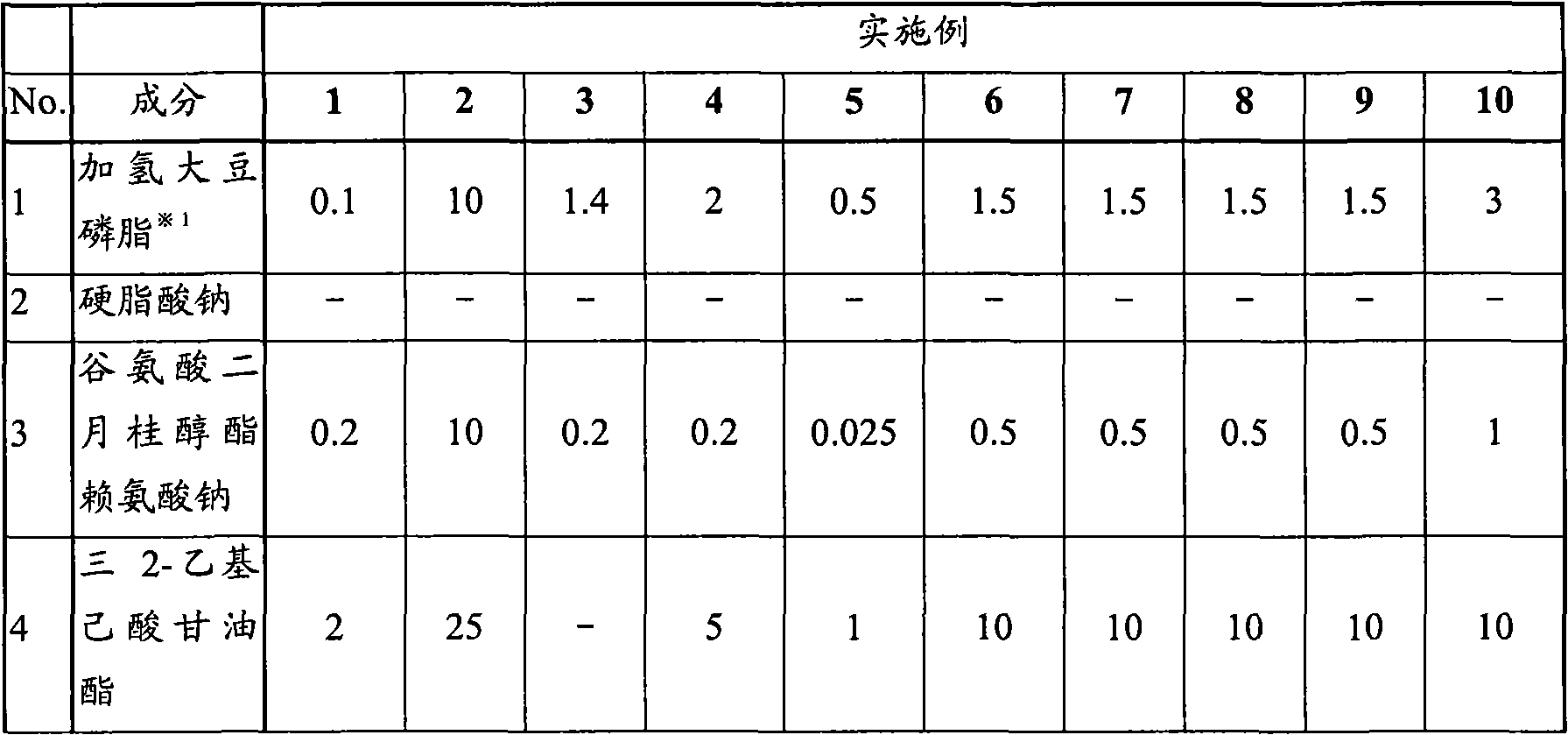

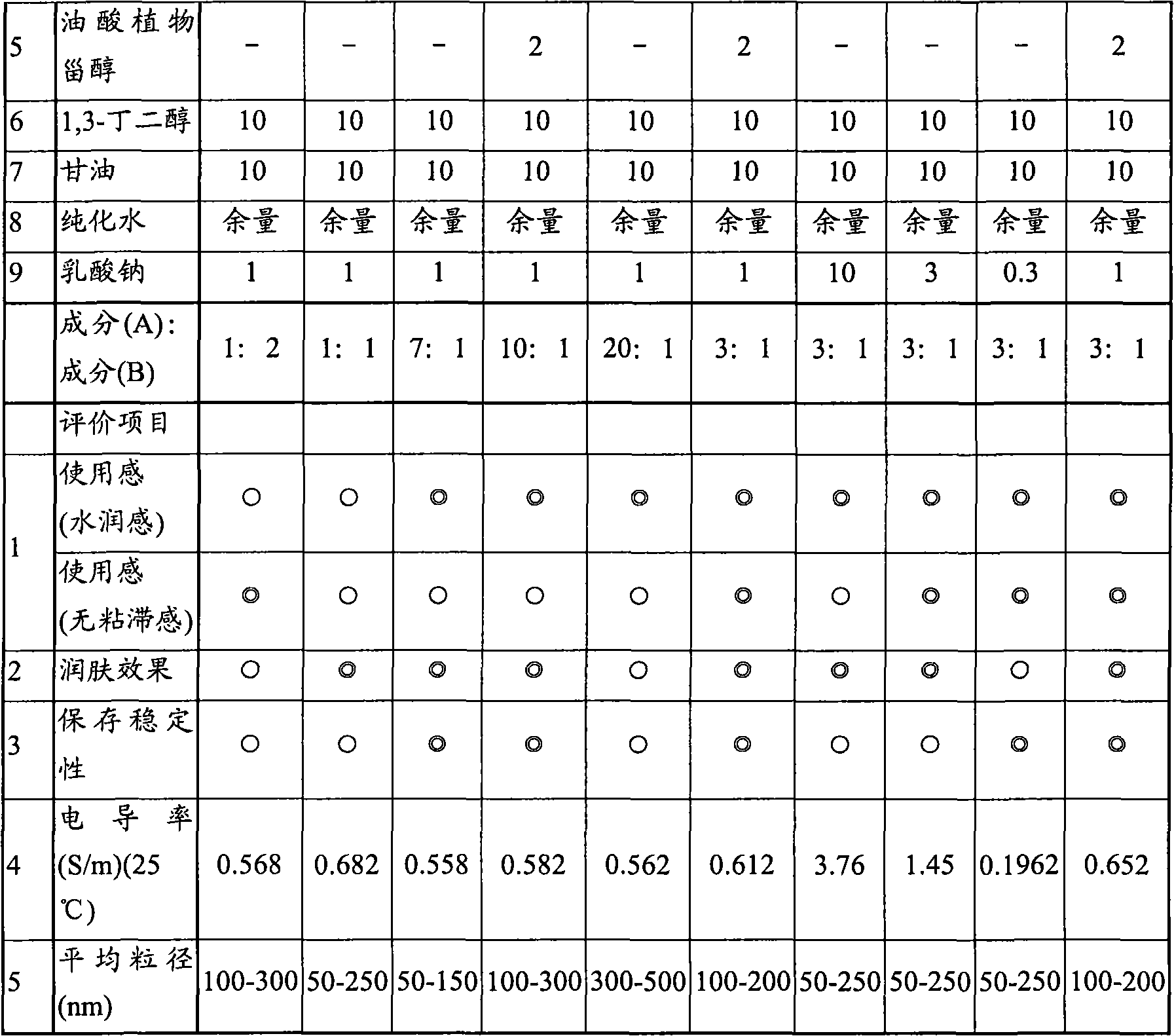

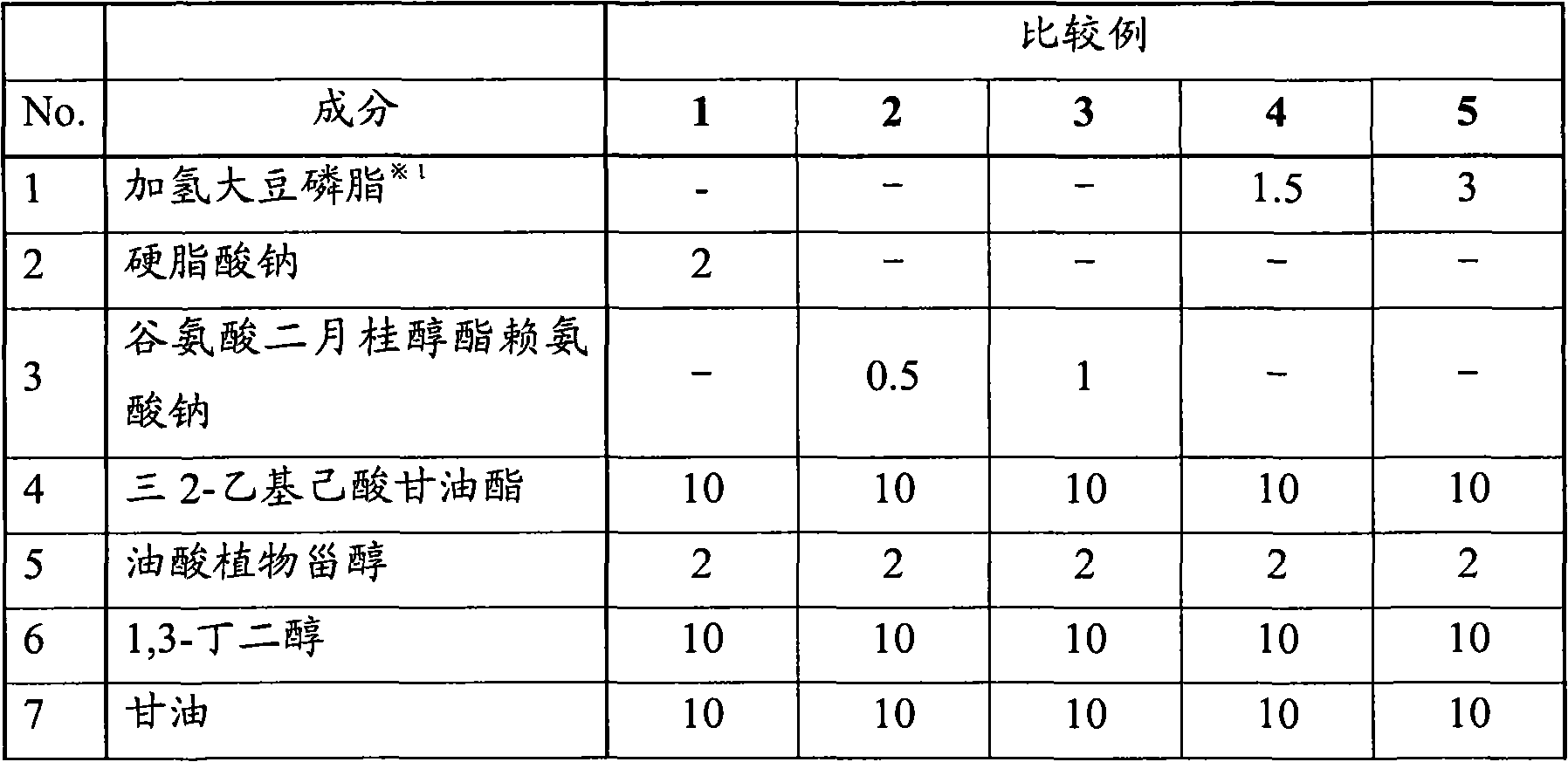

[0037] Examples 1-10 and Comparative Examples 1-5 liquid cosmetics

[0038] The liquid cosmetics with the composition shown in the following Table 1 and Table 2 were prepared according to the following preparation method. Evaluation items related to (1) feeling of use (moisture feeling, non-sticky feeling), (2) emollient effect, (3) storage stability, (4) electrical conductivity, (5) average particle size of emulsified droplets The following methods were used for evaluation, and all the results are shown in Table 1 and Table 2.

[0039] Table 1

[0040]

[0041]

[0042] ※1: Lecinol S-10EX (manufactured by NIKKO CHEMICALS); PC purity 75-85%, iodine value 6.6

[0043] Table 2

[0044]

[0045]

[0046] (Preparation)

[0047] A: Mix and dissolve 1-7. (70°C)

[0048] B: Heat 8. (70°C)

[0049] C: Add B to A to emulsify. (70°C)

[0050] D: Cool C to 40°C.

[0051] E: Disperse D using a microfluidizer.

[0052] F: Add 9 to E.

[0053] [Evaluation method...

Embodiment 11

[0076] Embodiment 11 whitening lotion

[0077] (Element) (%)

[0078] (1) Hydrogenated soybean lecithin ※1 0.5

[0079] (2) Sodium Dilauryl Glutamate Lysine 0.1

[0080] (3) Cetyl 2-ethylhexanoate 2.0

[0081] (4) 12-Hydroxy fatty acid / stearic acid / citronellic acid dipentaerythritol ester 0.05

[0082] (5) Stearic acid 0.05

[0083] (6) Dipropylene glycol 2.0

[0084] (7) Glycerin 3.0

[0085] (8) Purified water 10.0

[0086] (9) Magnesium L-Ascorbyl-2-phosphate 3.0

[0087] (10) Sodium citrate 1.0

[0088] (11) Methyl p-hydroxybenzoate appropriate amount

[0089] (12) Appropriate amount of spices

[0090] (13) Ethanol 10.0

[0091] (14) Purified water balance

[0092] (Preparation)

[0093] A: Mix and dissolve 1-7. (70°C)

[0094] B: Heat 8. (70°C)

[0095] C: Add B to A to emulsify. (70°C)

[0096] D: Cool C to 40°C.

[0097] E: Disperse D using a high-pressure homogenizer.

[0098] F:...

Embodiment 12

[0100] Embodiment 12 Emollient beauty lotion

[0101] (Element) (%)

[0102] (1) Hydrogenated soybean lecithin ※1 1.0

[0103] (2) Sodium Dilauryl Glutamate Lysine 0.2

[0104] (3) Sodium stearyl methyl taurate 0.05

[0105] (4) Cetyl 2-ethylhexanoate 2.0

[0106] (5) Cholesteryl Hydroxystearate 0.5

[0107] (6) Propylene Glycol 3.0

[0108] (7) Glycerin 3.0

[0109] (8) Purified water 20.0

[0110] (9) Sodium Lactate 2.0

[0111] (10) Sodium pyrrolidone carboxylate 2.0

[0112] (11) Methyl p-hydroxybenzoate appropriate amount

[0113] (12) Appropriate amount of spices

[0114] (13) Ethanol 5.0

[0115] (14) Purified water balance

[0116] (Preparation)

[0117] A: Mix and dissolve 1-7. (70°C)

[0118] B: Heat 8. (70°C)

[0119] C: Add B to A to emulsify. (70°C)

[0120] D: Cool C to 40°C.

[0121] E: D is dispersed using a high-pressure emulsifier.

[0122] F: Add 9-14 to E.

[0123] Example 12 is an emollient be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com