Oil-in-water solid cosmetic and cosmetic

A technology of oil-in-water type and cosmetics, which is applied in the direction of packaging cosmetics, cosmetics, cosmetics, etc., which can solve the problems of hardening of cosmetics and damage to the sense of use, and achieve the effects of excellent durability, comfortable use, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~24 and comparative example 1~10

[0140] The oil-in-water type solid cosmetics (blush) of the composition (mass %) shown in Tables 1-4 were prepared according to the following manufacturing method, and the said evaluation was performed. The results are shown together in Tables 1-4.

[0141]

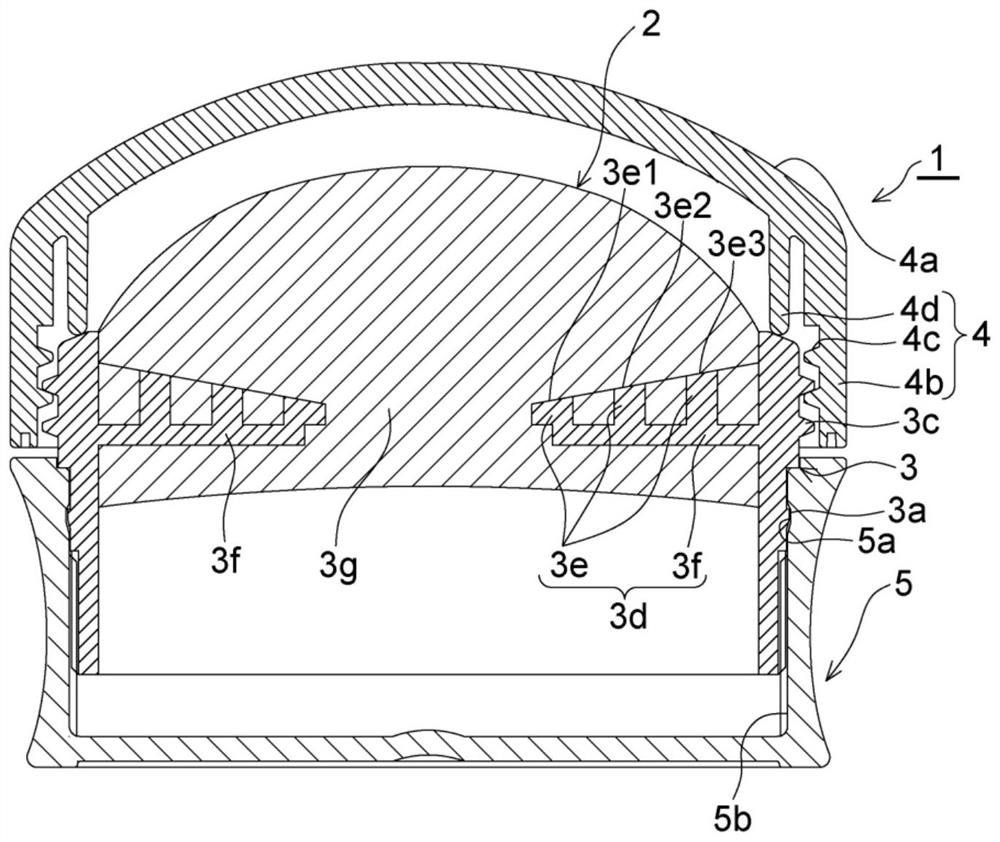

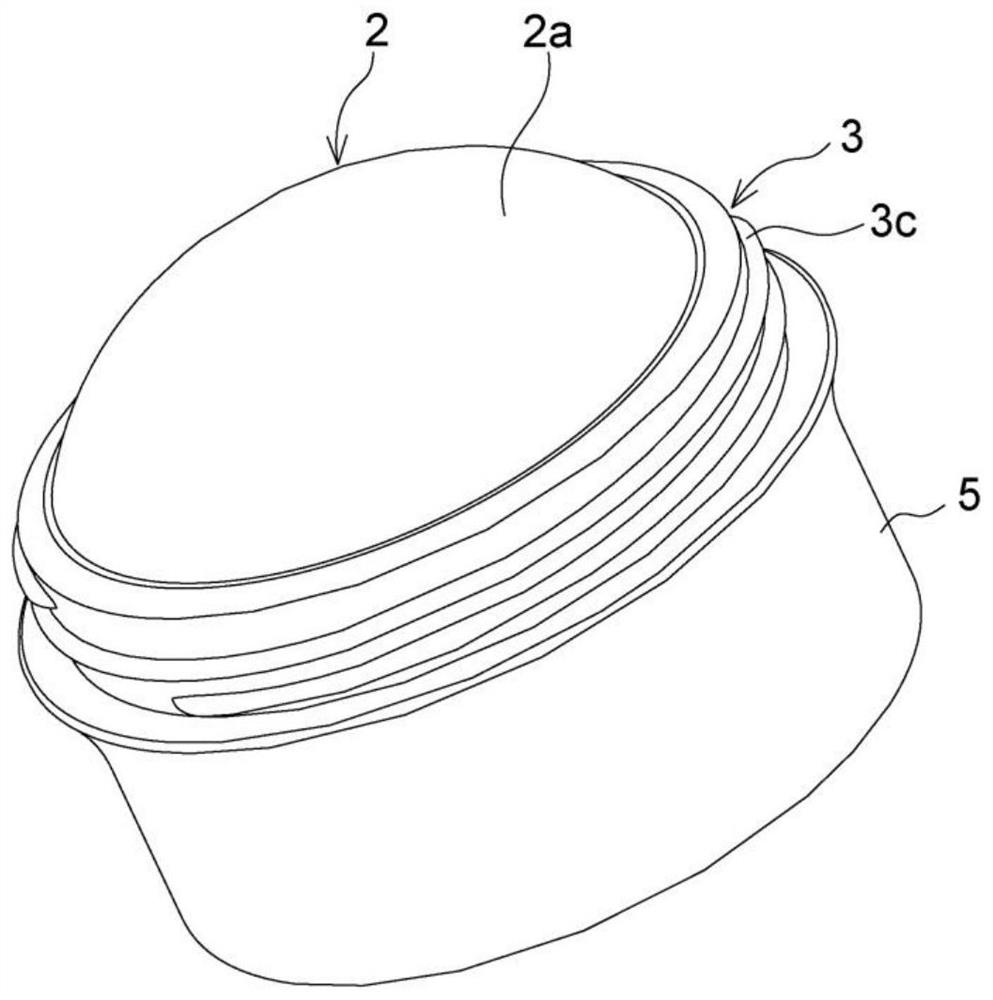

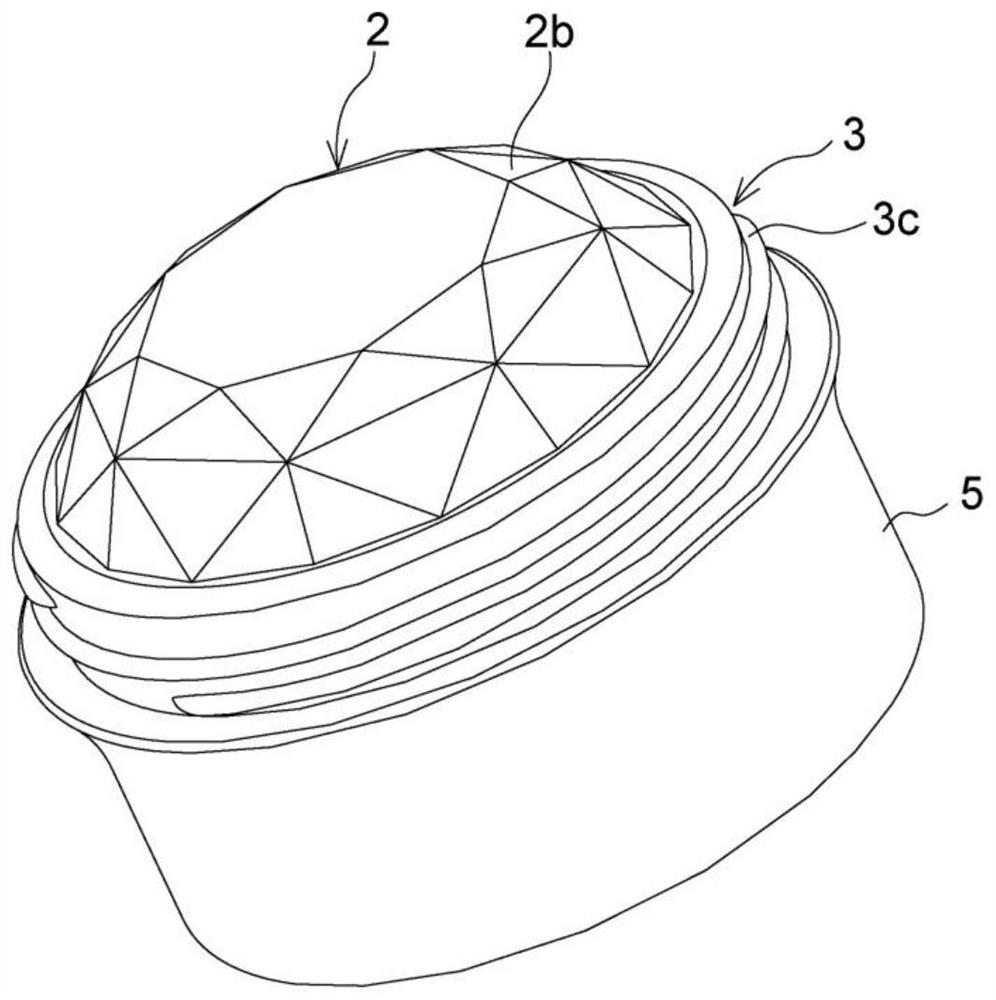

[0142] First, the water phase component is dispersed in purified water, and the above-mentioned dispersion liquid is heated to 90° C. or higher to dissolve, and the water phase portion is obtained. Next, the oil phase part in which the oil phase component was uniformly mixed was added to the water phase part, it stirred sufficiently, and emulsification was performed. The obtained solution is filled in a designated mold at 60°C or higher, and allowed to cool, thereby obtaining a figure 1 An oil-in-water type solid cosmetic of the same shape as the product shown. Then, the obtained solid cosmetic was moved into a designated container where the protrusions of the oil-in-water solid cosmetic could be exposed, and this was...

Embodiment 25

[0170] (Example 25: blush)

[0171]

[0172]

[0173]

[0174]

[0175]

[0176] Except for the components shown below, the details of the above-mentioned components are the same as those described above.

[0177] Polyacrylamide copolymer 2: product name: "SIMULGEL EG" (manufactured by SEPPIC) (mixture containing 40% by mass of (sodium acrylate / sodium acryloyldimethyltaurate) copolymer)

[0178]

[0179] First, the water phase component is dispersed in purified water, and the above-mentioned dispersion liquid is heated to 90° C. or higher to dissolve, and the water phase portion is obtained. Next, the oil phase part in which the oil phase component was uniformly mixed was added to the water phase part, it stirred sufficiently, and emulsification was performed. The obtained solution is filled in a designated mold at 60°C or higher, and allowed to cool, thereby obtaining a figure 1 An oil-in-water type solid cosmetic of the same shape as the product shown. Then...

Embodiment 26

[0182] (Example 26: Highlights)

[0183]

[0184]

[0185]

[0186]

[0187] The details of the above components are the same as those described above.

[0188]

[0189] First, the water phase component is dispersed in purified water, and the above-mentioned dispersion liquid is heated to 90° C. or higher to dissolve, and the water phase portion is obtained. Next, the oil phase part in which the oil phase component was uniformly mixed was added to the water phase part, it stirred sufficiently, and emulsification was performed. The obtained solution is filled in a designated mold at 60°C or higher, and allowed to cool, thereby obtaining a figure 1 An oil-in-water type solid cosmetic of the same shape as the product shown. Then, the obtained solid cosmetic was moved into a designated container where the protrusions of the oil-in-water solid cosmetic could be exposed, and this was used as a sample.

[0190]

[0191] The obtained highlights were evaluated in the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com