Heavy-oil cracking catalyst and preparation and application method thereof

A heavy oil cracking and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, molecular sieve catalysts, etc. The effect of strong resistance to heavy metals, high total yield, and strong calcium pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of catalyst, this method comprises:

[0027] Mix and beat retort earth, the first heat-resistant inorganic oxide and / or its precursor, additives and water, raise the temperature to 60°C to 80°C, and stir at 60°C to 80°C for 30 to 120 minutes to obtain The first slurry, the amount of the retort earth, the first heat-resistant inorganic oxide and / or its precursor, additives and water is such that the solid content of the obtained first slurry is 10 to 60% by weight, and the rector earth , the first heat-resistant inorganic oxide and / or its precursor and the amount of auxiliary agent make retort earth: heat-resistant inorganic oxide: the weight ratio of auxiliary agent in terms of elements is 45~94.9:5~50:0.1~20 , the auxiliary agent is one or a mixture of two compounds of Mn, P and Ce;

[0028] Mix the first slurry with modified ultra-stable Y-type zeolite to make a second slurry, or dry the first slurry, and mix the drie...

Embodiment 1

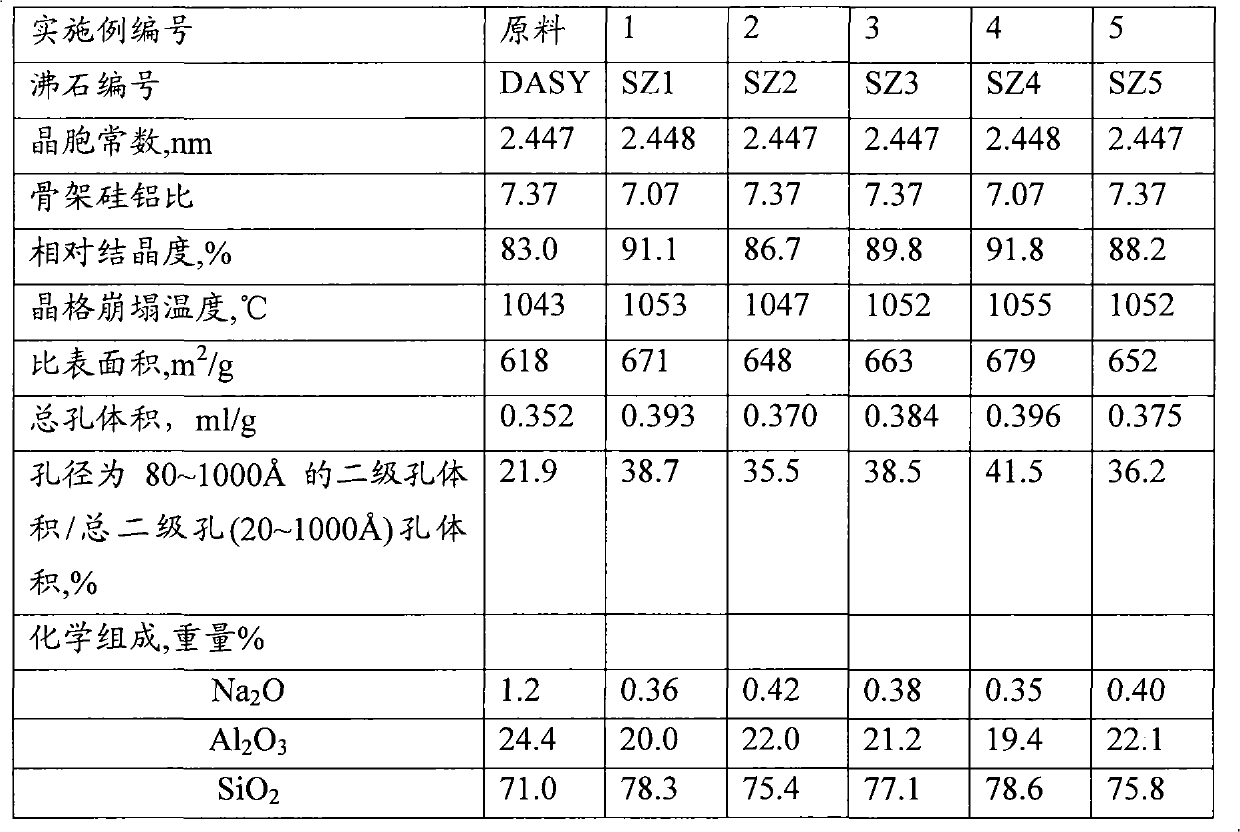

[0044] At room temperature, take 1000 grams (dry basis) of ultra-stable Y-type zeolite DASY, add it to 10 liters of mixed acid aqueous solution with a concentration of 0.2N oxalic acid and a concentration of 0.1N hydrochloric acid, stir to make it evenly mixed, and put it into a closed pressure reactor In, filled with N 2 , keep the pressure of the system at 0.12MPa (gauge pressure), raise the temperature to 100°C at a rate of 10°C / min, keep at this temperature and pressure for 1 hour, filter, wash, and dry at 120°C for 5 hours to obtain the modification The ultra-stable Y-type zeolite sample is denoted as SZ1. Table 1 shows the composition of SZ1, unit cell constant, relative crystallinity, structure collapse temperature, specific surface area and larger pore size (pore size is 80~ ) of secondary pores accounted for the total secondary pores (20~ ) percentage.

Embodiment 2

[0046] At room temperature, take 2000 grams (dry basis) of ultra-stable Y-type zeolite DASY, add it to 20 liters of mixed acid aqueous solution with a concentration of acetic acid of 0.1N and a concentration of hydrochloric acid of 0.15N, stir to make it evenly mixed, and put it into a closed pressure reactor , filled with N 2 , control the pressure of the reactor to 0.3MPa (gauge pressure), raise the temperature to 115°C at a heating rate of 10°C / min, and keep it at this temperature and pressure for 30 minutes, then filter, wash, and dry the filter cake at 120°C for 5 hours , to obtain the modified ultrastable Y-type zeolite sample, denoted as SZ2, table 1 has provided the composition of SZ2, unit cell constant, relative crystallinity, structure collapse temperature, specific surface area and larger pore diameter (pore diameter is 80~ The secondary pores accounted for the total secondary pores (20~ ) percentage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com