Low temperature microwave medium ceramic materials without glass phase additions

A technology of microwave dielectric ceramics and glass phase, which is applied in the field of adding low-temperature microwave dielectric ceramic materials without glass phase, which can solve the problems of terminal electrode cracking and lower Q value of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

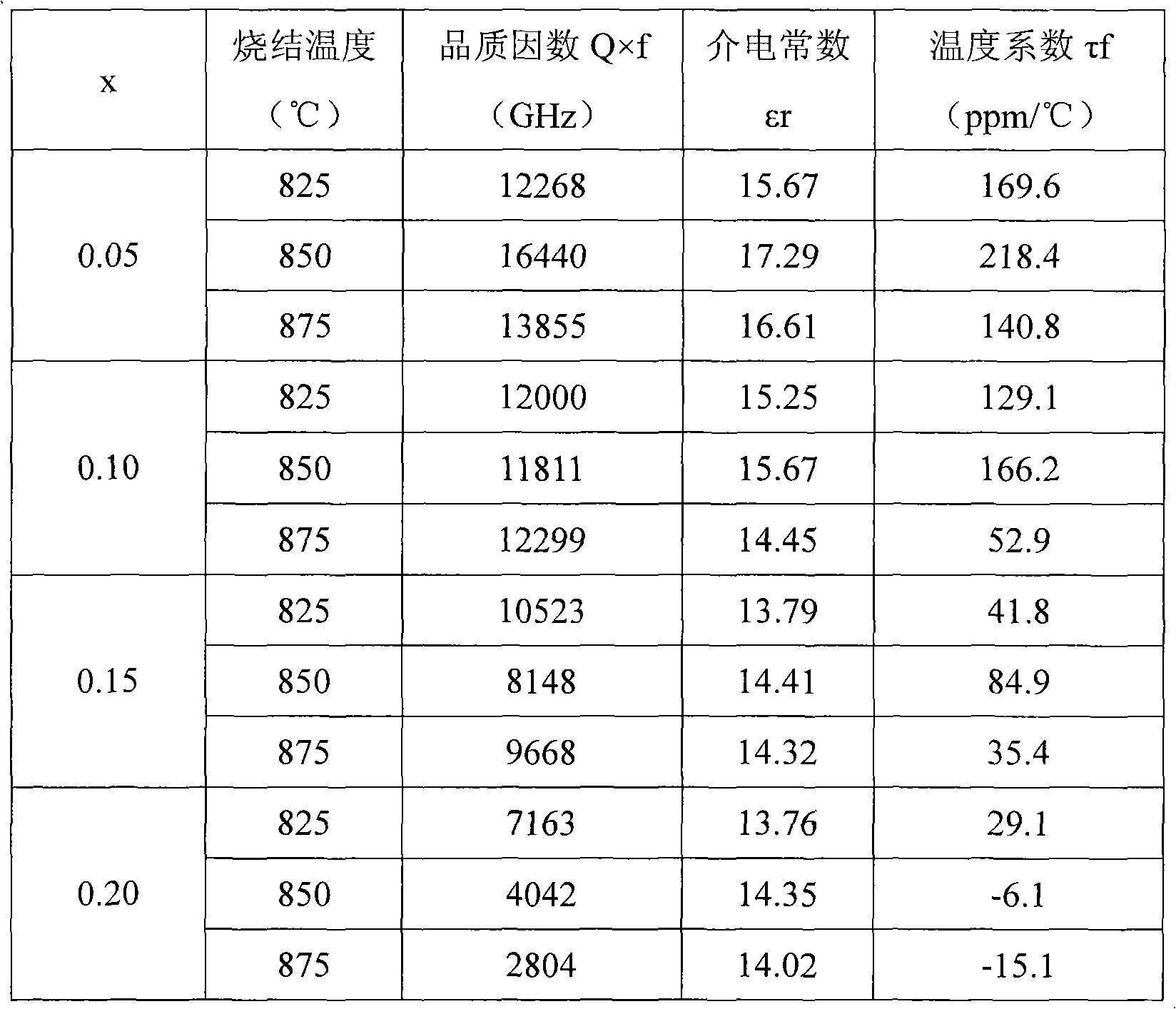

[0023] Embodiment one: according to LiY(W 1-x Te x ) 2 o 8 (x=0.05~0.20) chemical equation, convert the quality of each raw material required, and then accurately weigh each analytical pure raw material: Li 2 CO 3 (99.9%); Y 2 o 3 (99.9%); WO 3 (99%); TeO 2 (99.99%). The weighing quality is as follows: Table 1

[0024] Table 1LiY(W 1-x Te x ) 2 o 8 Ingredients list (unit: g)

[0025] x

Li 2 CO 3

Y 2 o 3

WO 3

TeO 2

0.05

6.3120

19.2897

75.9418

2.7242

0.10

6.3732

19.4766

72.6422

5.5013

0.15

6.4356

19.6672

69.2779

8.3327

[0026] x

Li 2 CO 3

Y 2 o 3

WO 3

TeO 2

0.20

6.4992

19.8616

65.8472

11.2202

[0027] Put the accurately weighed raw materials into the resin ball mill tank, add alcohol and ZrO 2 Grinding balls; the weight ratio of the three is: material: ball: alcoh...

Embodiment 2

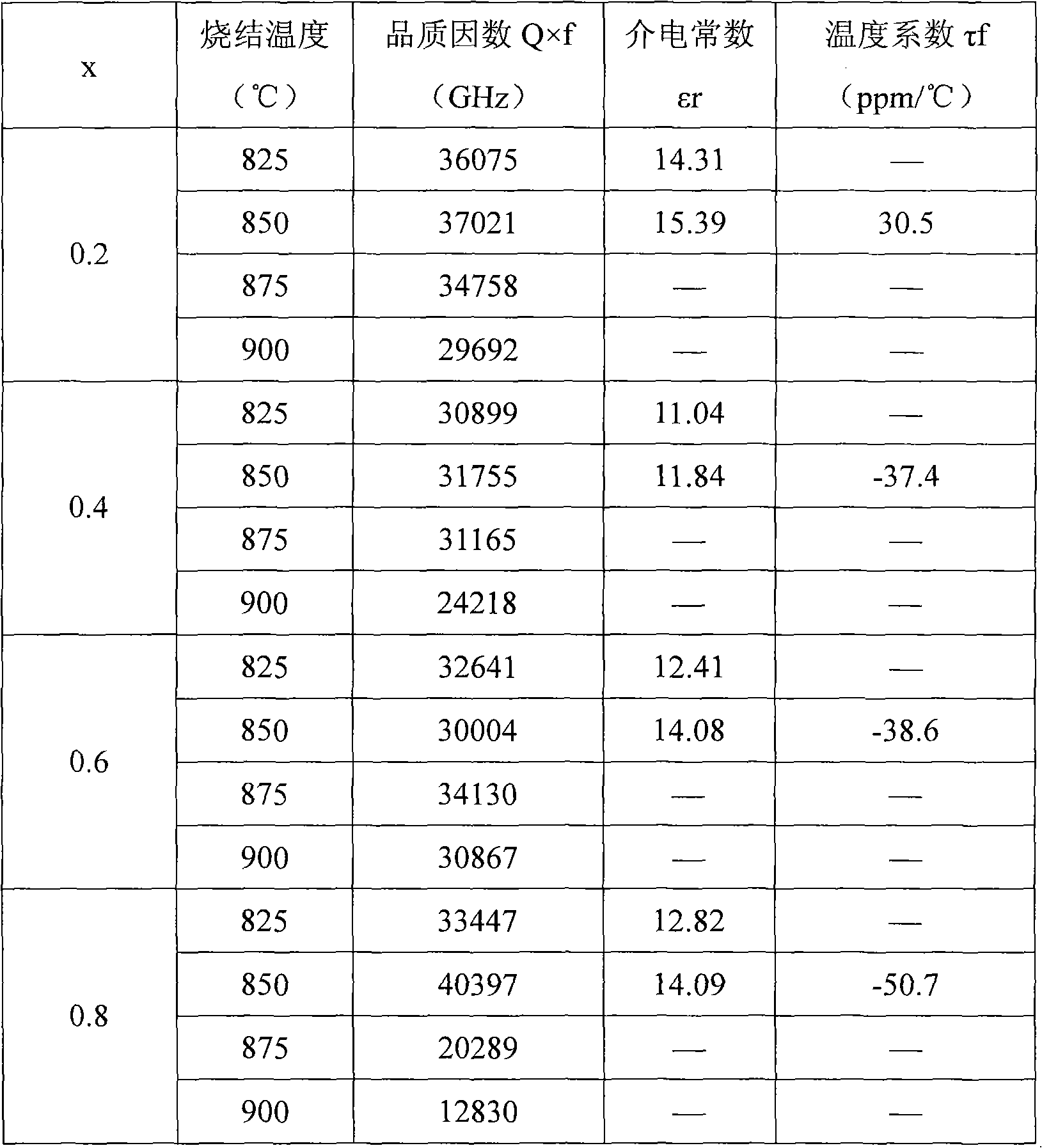

[0031] Embodiment two: according to (1-x) LiYW 2 o 8 -xZnW 0.9 Te 0.1 o 4 (x=0.2~0.8) chemical equation, convert the quality of each raw material required, and then accurately weigh each analytical pure raw material: Li 2 CO 3 (99.9%); Y 2 o 3 (99.9%); WO 3 (99%); ZnO (99.6%) and TeO 2 (99.99%). The weighing quality is as follows: Table 3

[0032] Table 3(1-x)LiYW 2 o 8 -xZnW 0.9 Te 0.1 o 4 Ingredients list (unit: g)

[0033] x

Li 2 CO 3

Y 2 o 3

WO 3

ZnO

TeO 2

0.2

5.5327

16.9081

77.9522

3.0563

0.5969

0.4

4.6425

14.1877

76.4341

6.8388

1.3358

0.6

3.5123

10.7336

74.5068

11.6413

2.2738

0.8

2.0298

6.2031

71.9788

17.9405

3.5042

[0034] The material preparation process and testing method are the same as in Example 1. The results are shown in Table 4:

[0035] Table 4(1-x)LiYW 2 o 8 -xZ...

Embodiment 3

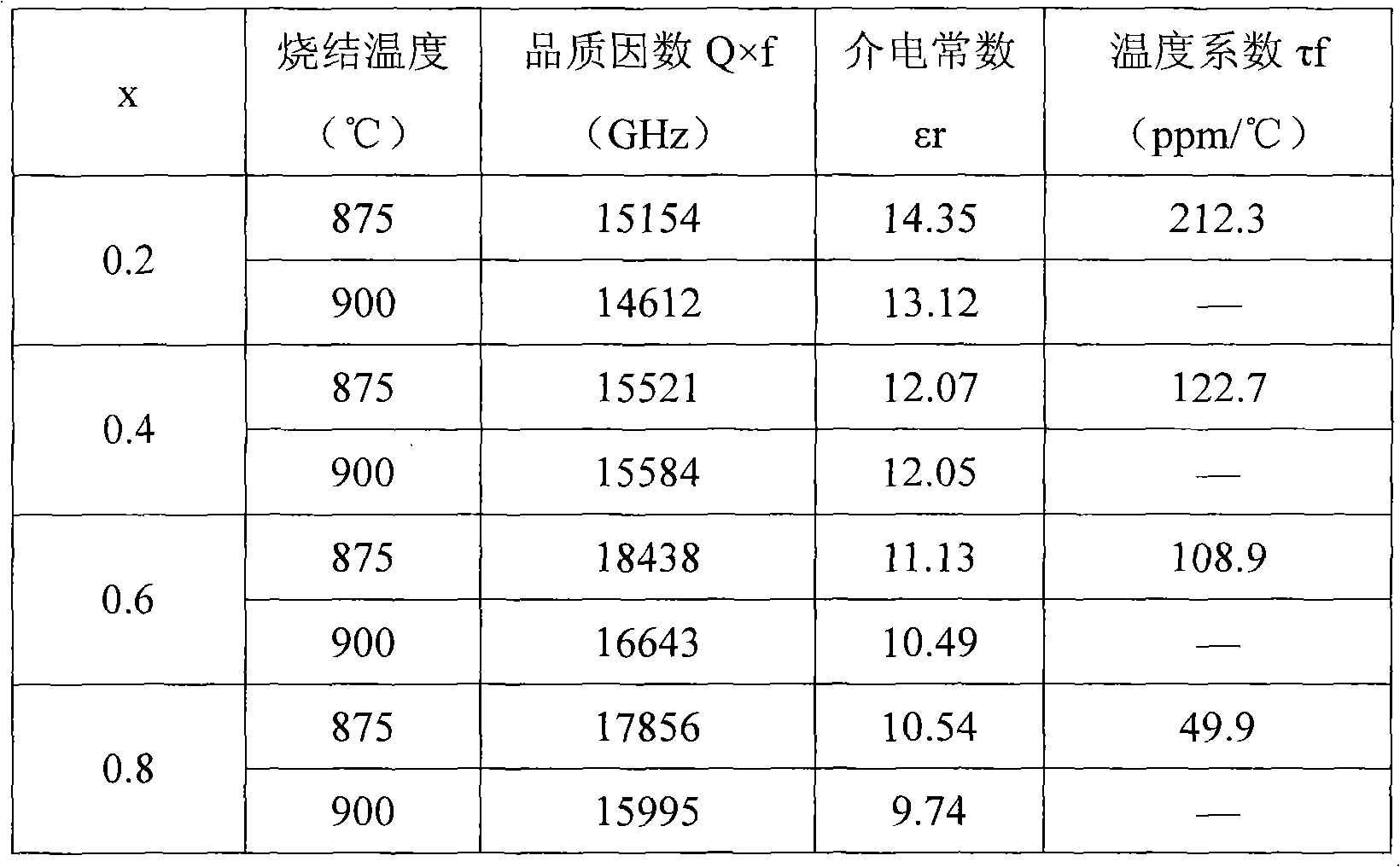

[0037] Embodiment three: according to (1-x)LiYW 2 o 8 -xSrWO 4 (x=0.2~0.8) chemical equation, convert the quality of each raw material required, and then accurately weigh each analytical pure raw material: Li 2 CO 3 (99.9%); Y 2 o 3 (99.9%); WO 3 (99%) and SrCO 3 (99.5%). The weighing quality is as follows: Table 5

[0038] Table 5(1-x)LiYW 2 o 8 -xSrWO 4 Ingredients list (unit: g)

[0039] x

Li 2 CO 3

Y 2 o 3

WO 3

SrCO 3

0.2

5.4757

16.7338

78.0153

5.4920

0.4

4.5368

13.8645

76.6082

12.1343

0.6

3.3783

10.3240

74.8720

20.3301

0.8

1.9128

5.8457

72.6758

30.6971

[0040] The material preparation process and testing method are the same as in Example 1. The results are shown in Table 6:

[0041] Table 6(1-x)LiYW 2 o 8 -xSrWO 4 (x=0.2~0.8)Microwave dielectric properties of materials

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com