Preparation method for polystyrene latex with carboxyl on surface and for immunoassay technology

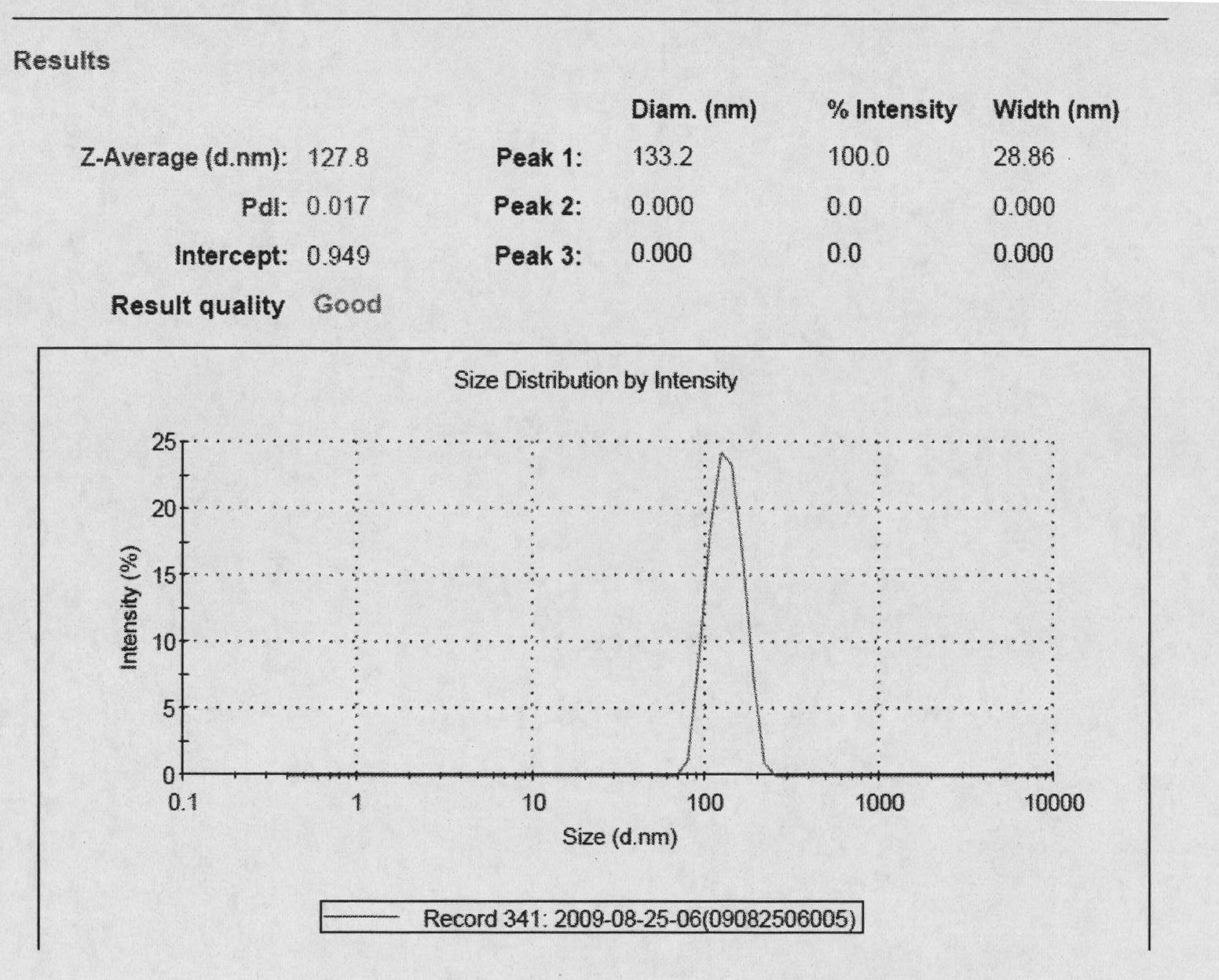

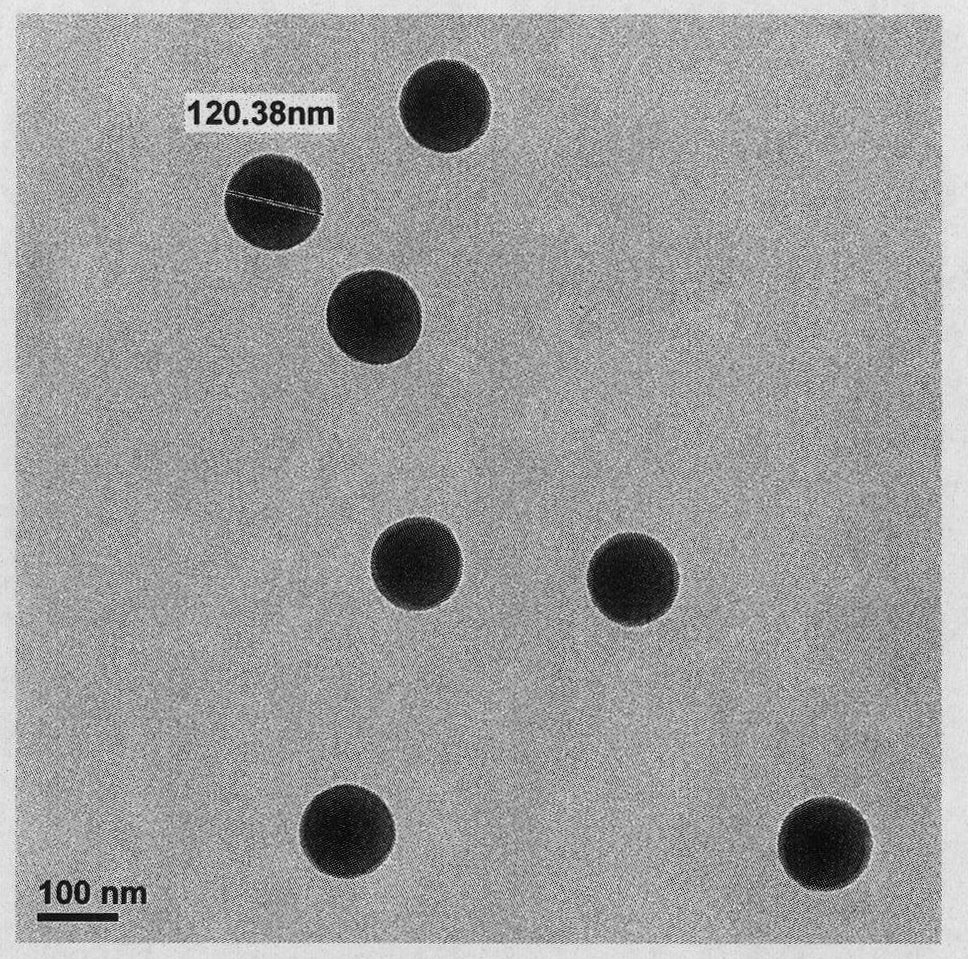

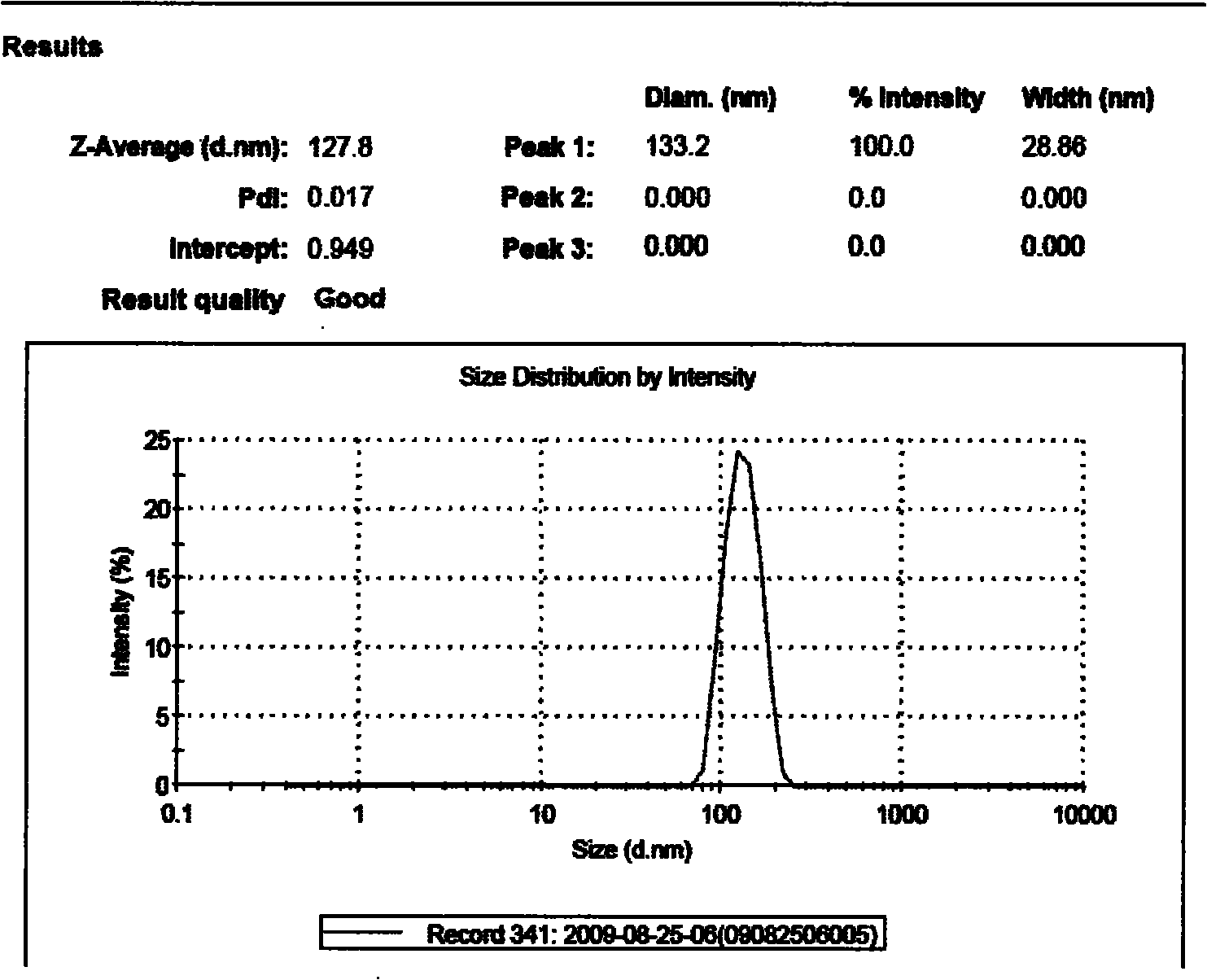

A technology of polystyrene latex and immunoassay, which is applied in the direction of measuring devices, instruments, and analytical materials, etc., can solve the problems of unsatisfactory particle size uniformity of latex particles, affecting the performance of latex, and affecting the accuracy of measurement, etc., to achieve surface Clean, good measurement effect, uniform particle size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Add styrene, methacrylic acid, and water to a three-necked flask and stir for 10 minutes; the above-mentioned styrene is 0.041mol, methacrylic acid is 8.7mmol, and water is 10ml;

[0031] (2) After the reaction system stirring of step (1) gained finishes, in the reaction system, pass into the N of 30min 2 , then about 0.066g of potassium persulfate and about 0.207g of sodium chloride were added to 40ml of water to configure an aqueous solution, and the above-mentioned aqueous solution was added to the reaction system. After the addition, the concentration of NaCl in the reaction system was 0.064mol / The concentration of L and KPS is 4.38×10 -3 mol / L (total water consumption is the water that step (1) adds and step (2) configures the used water of sodium chloride and potassium persulfate to be 50ml, configures the used water of NaCl and KPS aqueous solution just to ensure that NaCl and KPS Completely dissolve in water, because if NaCl and KPS are added to the reacti...

Embodiment 2

[0038] (1) Add styrene, methacrylic acid, and water to a three-necked flask and stir for 10 minutes; the above-mentioned styrene is 0.041mol, methacrylic acid is 8.7mmol, and water is 10ml;

[0039] (2) After the reaction system stirring of step (1) gained finishes, in the reaction system, pass into the N of 30min 2, then about 0.117g of potassium persulfate and about 0.207g of sodium chloride are added to 40ml of water to configure an aqueous solution, and the above-mentioned aqueous solution is added to the reaction system. After the addition, the concentration of NaCl in the reaction system is 0.064mol / The concentration of L and KPS is 7.88×10 -3 mol / L, and then continue to pass through 20min of N 2 , in the whole reaction system, the total amount of the added water is 50ml, and now the concentration of the methacrylic acid added in step (1) in the total water consumption is 0.174mol / L;

[0040] (3) After the nitrogen feed is completed, the reaction system obtained in st...

Embodiment 3

[0044] (1) Add styrene, methacrylic acid, and water to a three-necked flask and stir for 10 minutes; the above-mentioned styrene is 0.041mol, methacrylic acid is 8.7mmol, and water is 10ml;

[0045] (2) After the reaction system stirring of step (1) gained finishes, in the reaction system, pass into the N of 30min 2 , and then about 0.12g of potassium persulfate and about 0.207g of sodium chloride are added to 40ml of water to configure an aqueous solution, and the above-mentioned aqueous solution is added to the reaction system. After the addition, the concentration of NaCl in the reaction system is 0.064mol / The concentration of L and KPS is 8.14×10 -3 mol / L, and then continue to pass through 20min of N 2 , in the whole reaction system, the amount of water added is 50mL, and now the concentration of the methacrylic acid added in step (1) in the total water consumption is 0.174mol / L;

[0046] (3) After the nitrogen feed is completed, the reaction system obtained in step (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com