Alloying treatment method for surface of spheroidal graphite cast iron roll

A roll surface, nodular cast iron technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as block loss and roll scrapping, reduce driving force, reduce high temperature temper softening, and have good temper softening resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

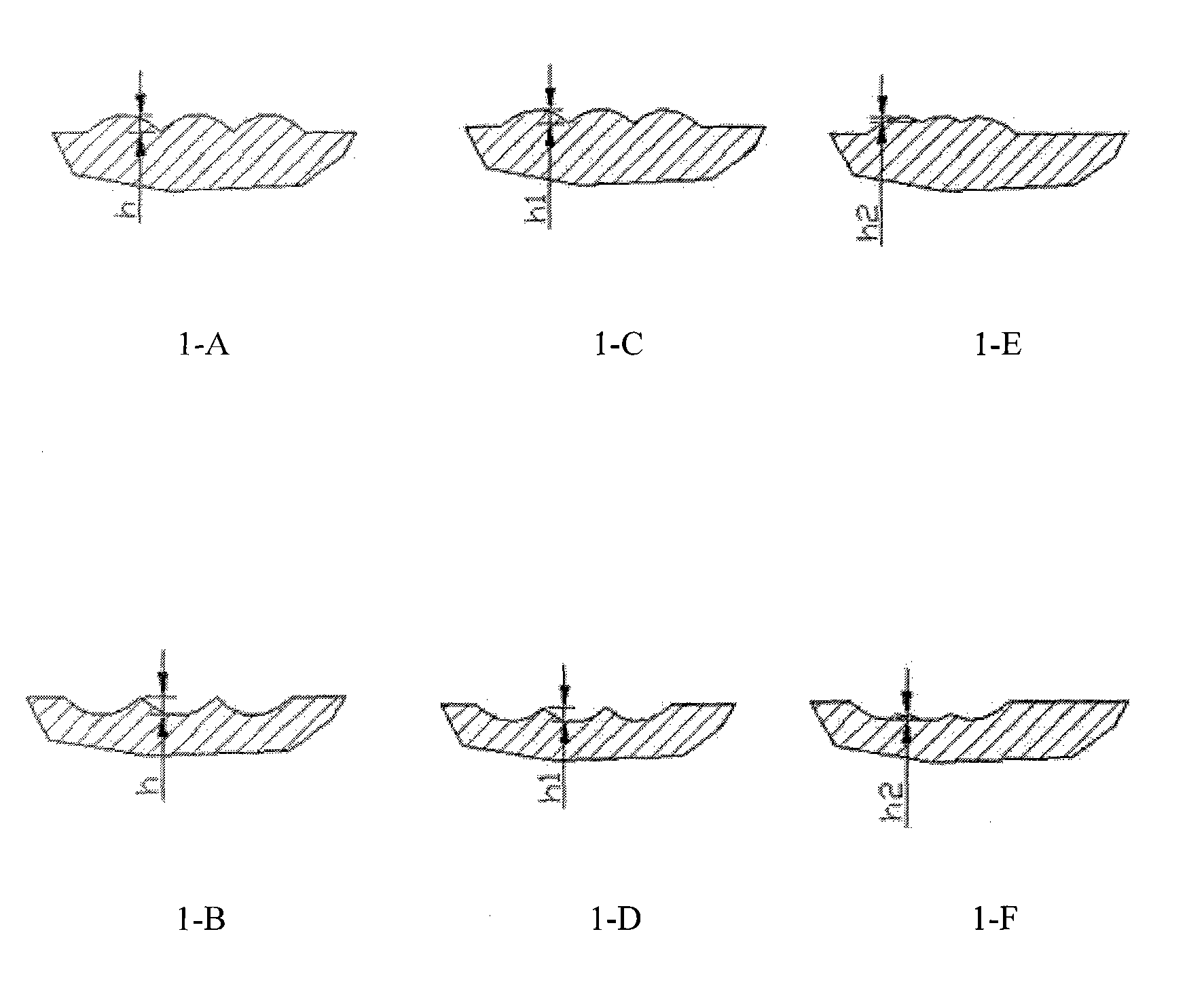

Image

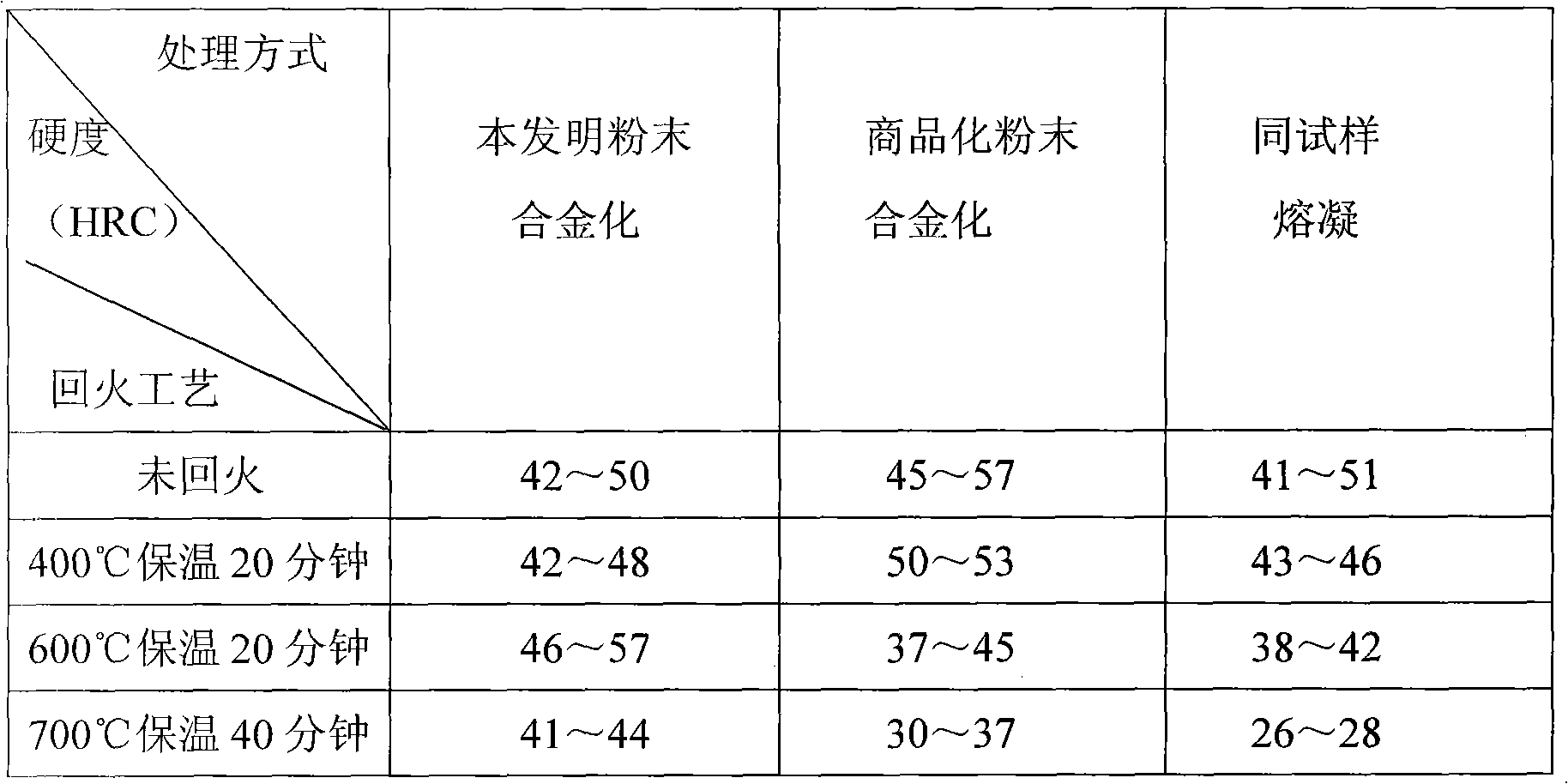

Examples

Embodiment 1

[0043] The inventive method is used for strengthening the method step of angle steel ductile iron finishing roll as follows:

[0044] (1) Install the roll on the machine tool, its axis is along the horizontal direction and can rotate around the axis;

[0045] (2) Derusting with sandpaper or grinding wheel;

[0046] (3) Clean the working surface of the roll with alcohol or acetone until the surface is free of oil and smooth;

[0047] (4) Use absolute alcohol to adjust 94wt% alloy powder and 6wt% phenolic resin, or 97wt% alloy powder and 3wt% phenolic resin into a paste-like alloyed coating, and evenly coat it on the working surface. Layer thickness 0.1 or 0.12mm, and dry or blow dry;

[0048] (5) Turn on CO 2 Cross-flow laser, the laser output power is 3.5 or 4.0KW, the spot is adjusted to Ф2.8mm or Ф3.5mm, aligned with the scanning start point, the scanning speed is 1.8m / min or 2.2m / min, and blowing argon or helium protection at the same time , the protective gas output pr...

Embodiment 2

[0054] The inventive method is used for strengthening ductile iron I-beam finishing roll method step as follows:

[0055] (1) derusting the surface of the roll to be treated with sandpaper or emery wheel;

[0056] (2) Clean the working surface of the roll with alcohol or acetone until the surface is free of oil and smooth;

[0057] (3) Use anhydrous alcohol to adjust 98wt% alloy powder and 2wt% phenolic resin into a paste-like alloyed coating, and evenly coat the working surface with a coating thickness of 0.13 or 0.15mm, and dry or blow dry ;

[0058] (4) Turn on CO 2 Cross-flow laser, laser output power 4.5KW, adjust the spot to Ф3.8mm, scan speed 2.1m / min, blow nitrogen protection at the same time, the output pressure of the protection gas is 0.2Mpa, and align with the scanning starting point;

[0059] (5) The scanning trajectory of the laser beam is a spiral continuous overlapping method, and the overlapping rate is 47% or 48%;

[0060] (6) Repeat steps (4) and (5) unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap