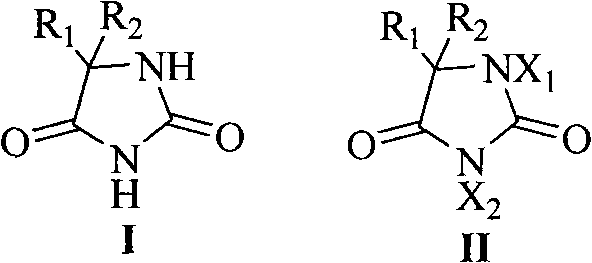

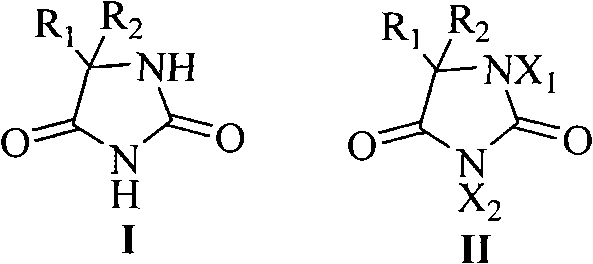

Electrochemical synthesis method for preparing halogenated hydantoin

A technology of dihalogenated hydantoin and a synthesis method, which is applied in the electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of difficult control of liquid bromine or chlorine gas production, obvious decomposition of hydantoin, strong alkalinity of solution, etc. The feeding operation is convenient and simple, the raw materials are cheap and easy to obtain, and the production cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 30mL water, 1.28g (0.01mol) dimethyl hydantoin and 1.90g (0.02mol) magnesium chloride into a 100mL flask, insert an electrode with both cathode and anode Pt, connect the circuit, and conduct electrolysis, keep the current at 0.05A (use Electrode area is 1cm 2 ), while stirring, add dilute hydrochloric acid dropwise during the electrolysis process to make the pH at 2, electrolysis for 21.5 hours (approximately equal to the theoretical time value), filter, wash with water, and dry to obtain the product dichlorodimethylhydantoin 0.49g, yield 25.0%

Embodiment 2

[0031] Add 30mL of 0.2g / mL sodium chloride solution, 1.28g (0.01mol) dimethylhydantoin into a 100mL flask, insert the electrode with Au for anode and C for cathode, connect the circuit, energize and electrolyze, keep the current at 0.5A (the electrode area is 1cm 2 ), while stirring, add dilute hydrochloric acid dropwise during the electrolysis process to make the pH between 4-5, electrolyze for 10.5 hours (approximately 5 times the theoretical time value), filter, wash, and dry to obtain 1.42g of dichlorodimethylhydantoin. The yield was 72.3%

Embodiment 3

[0033] Add 30mL water, 2.80g (0.01mol) dimethylphenylhydantoin and 1.90g (0.02mol) magnesium chloride into a 100mL flask, insert an electrode with Pt both at the cathode and anode, connect the circuit, energize the electrolysis, and keep the current at 0.1 A (The electrode area is 1cm 2 ), while stirring, add dilute hydrochloric acid dropwise during the electrolysis process to make the pH 6-7, electrolyze for 10.5 hours (approximately equal to the theoretical time value), filter, wash, and dry to obtain 2.61g of product dichlorobis-p-methylphenylhydantoin , The yield is 75.0%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com