Independent tuning microwave electron gun with external cathode

A microwave electron gun and cathode technology, which is applied to circuits, electrical components, phonon exciters, etc., can solve the problems of large size and complex technology of microwave electron guns, and achieve the effects of reduced difficulty and complexity, low technical difficulty, and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

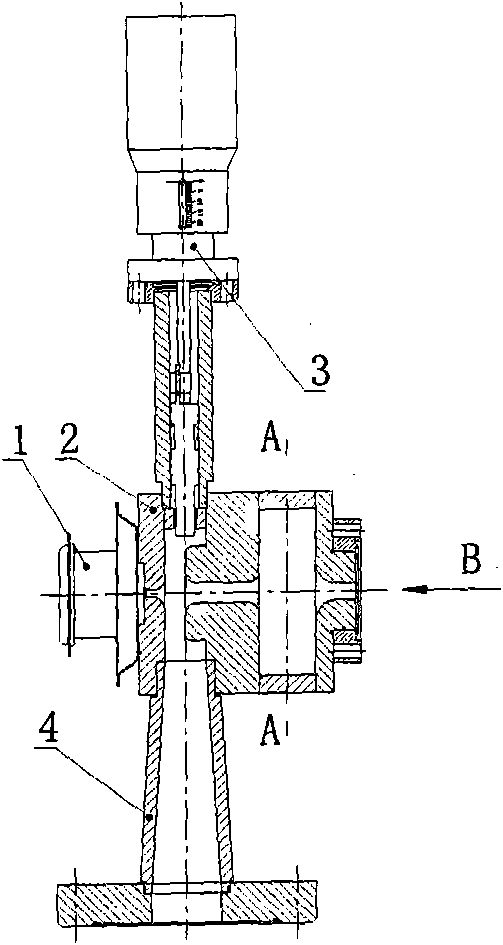

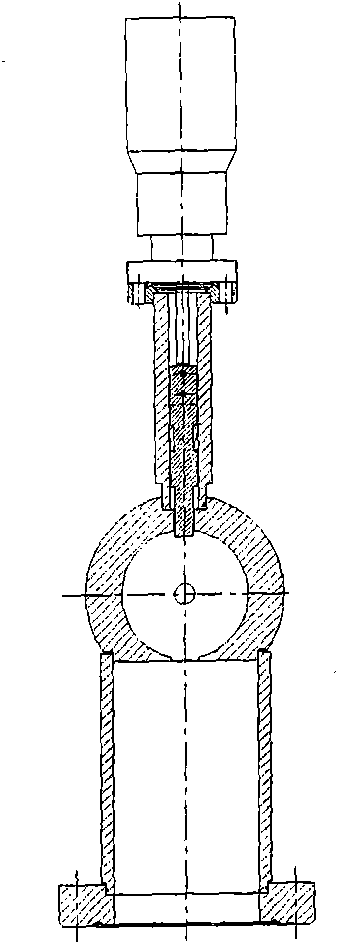

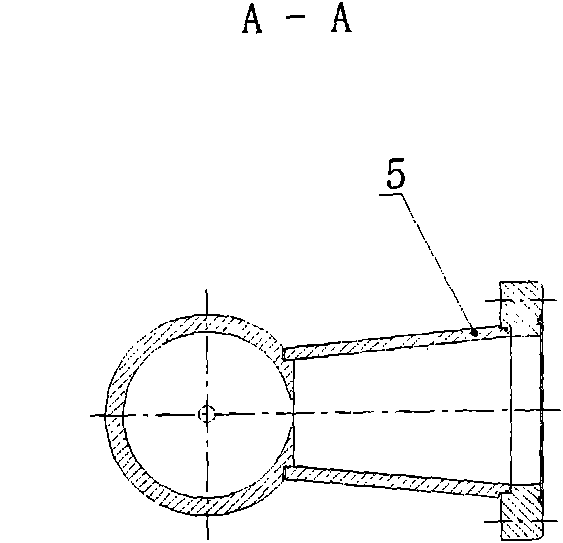

[0017] Such as Figures 1a-1d As shown, the external cathode independent tuning microwave electron gun of the present invention is composed of two closely connected microwave cavities 2 (S-band resonant cavity can be used) and an external thermal cathode 1 that are closely connected and the microwave power is isolated from each other; the external thermal cathode 1 is placed The outside of the microwave cavity 2 is integrated with the microwave cavity 2 through argon-arc welding of the dish-shaped flange 201 . The external hot cathode 1 is a purchased part. It has a hot cathode and an anode. The cathode and the anode of the external hot cathode 1 are insulated from each other by ceramic tubes, so as to add 15kV pulse high voltage to extract the electron beam; the electron beam current generated by the external hot cathode is required The intensity is 2A, the beam waist of the electron beam is in the center of the first cavity of the microwave cavity, the diameter of the beam w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com