Ultraviolet light catalyzing and strong oxidizing treatment method of ship ballast water

A technology for ship ballast water and treatment methods, which is applied in the field of ultraviolet photocatalytic strong oxidation ship ballast water treatment technology, can solve the problems of seawater secondary pollution, incomplete sterilization, poor treatment effect, etc., and achieves wide application range, Small negative impact, effect of improving water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

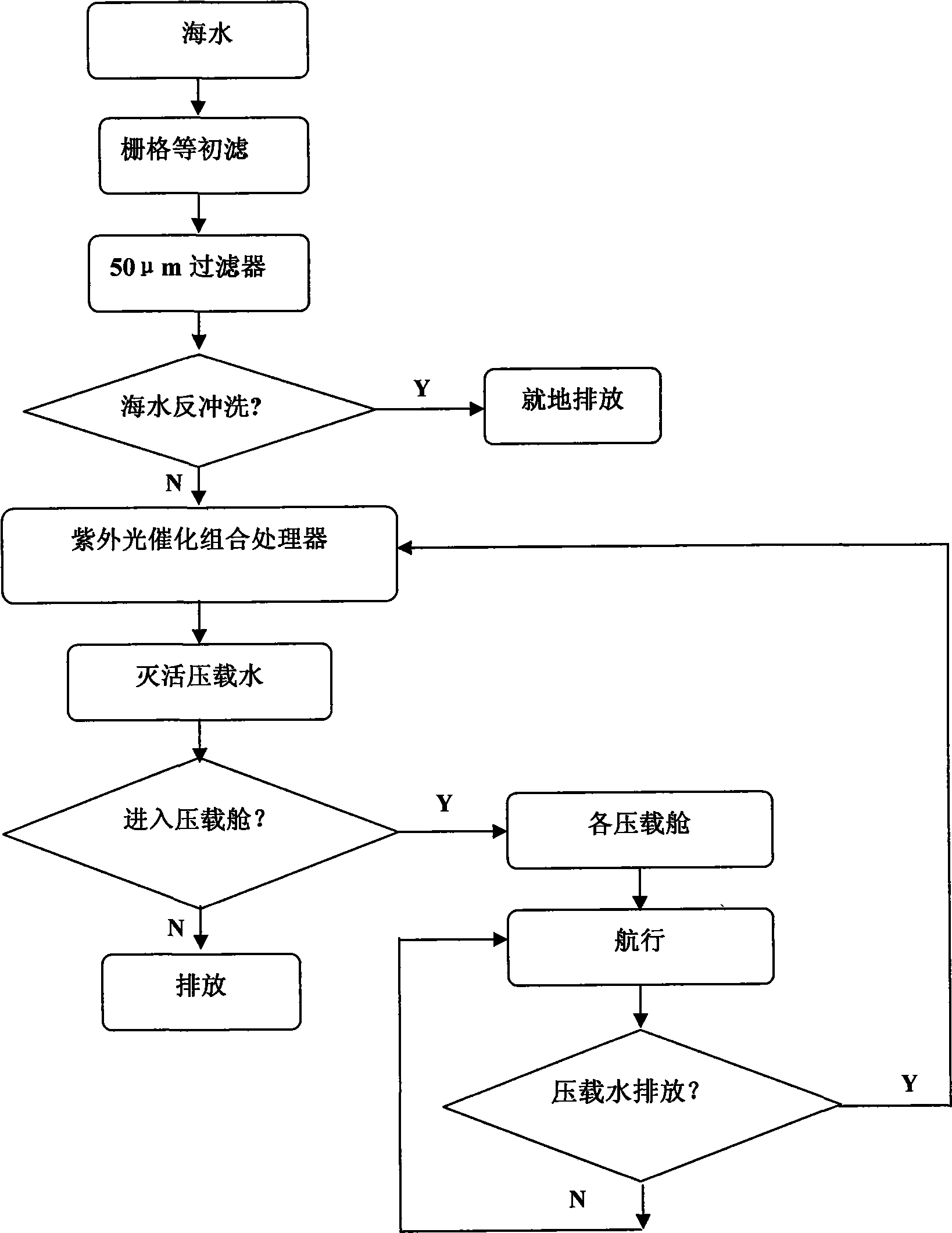

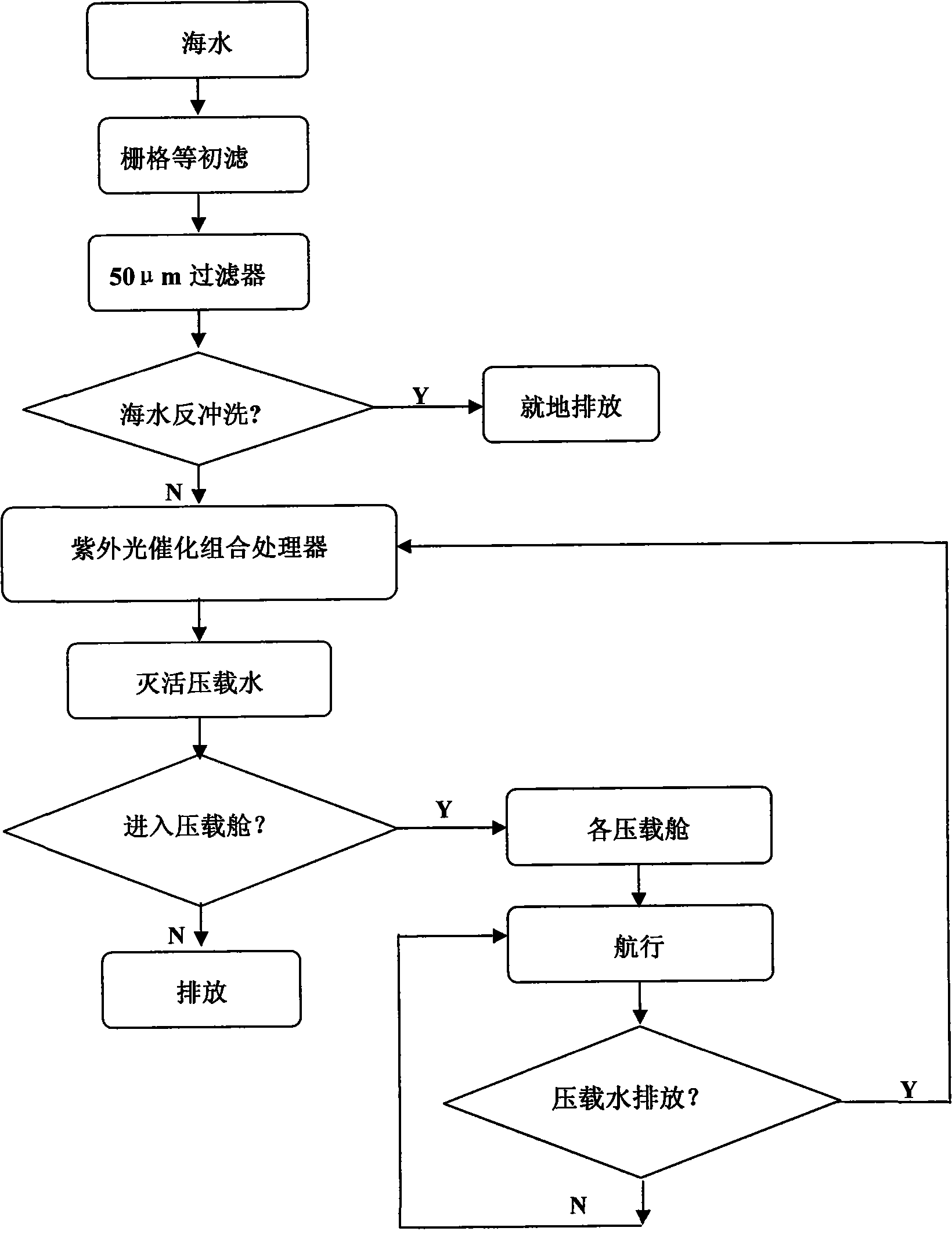

Method used

Image

Examples

Embodiment 1

[0040] The ballast water taken from the Yangshan Deepwater Port was first filtered through a filter with a pore size of 50 μm, and the concentration of algae with a diameter of less than 50 μm was 2.37×10 3 / ml, the bacterial concentration was 8.74×10 2 / ml, through a low-pressure mercury lamp with a dominant emission wavelength of 254nm and a thin-film TiO prepared on an industrially pure titanium sheet as a supporting substrate 2After 3 minutes of treatment in the photocatalytic strong oxidation reactor of the photocatalyst, the number of algae and bacteria was detected by the algae counting method and the ultraviolet-visible spectrometer method, and the algae and bacteria with a diameter of less than 50 μm were not detected, and the killing rate was 100% %, the ballast water treated by the method of the present invention can reach the index stipulated by the International Maritime Organization (IMO).

Embodiment 2

[0042] After the ballast water taken from Xiangshan Port in Ningbo is filtered through a filter with a pore size of 50 μm, the concentration of aquatic organisms with a diameter of less than 50 μm such as protozoa, algae, bacteria, and spores exceeds 3.5×10 4 / ml, and the COD of the ballast water is 0.62mg / L, through the low-pressure mercury lamp with the main emission wavelength of 185nm and the film-type TiO2 prepared on the support substrate of sponge-like porous ceramics 2 After 5 minutes of treatment in the photocatalytic strong oxidation reactor of the photocatalyst, protozoa, algae and bacteria were detected, and the results were not detected, and the killing rate reached 100%. No bacteria with a thickness of 50 μm has been detected, which proves that the method of the present invention can completely kill the spores; meanwhile, the COD of ballasted seawater is reduced to 0.11 mg / L, and the removal rate reaches more than 82%. The ballast water treated by the method of t...

Embodiment 3

[0044] After the ballast water taken from Xiangshan Port in Ningbo was filtered through a filter with a pore size of 50 μm, the concentration of aquatic organisms with a diameter of less than 50 μm such as protozoa, algae, bacteria, and spores exceeded 3.5×10 4 / ml, and the COD of the ballast water is 0.62mg / L, the film-type TiO2 prepared on the low-pressure mercury lamp with the emission dominant wavelength of 254nm and the glass ball with a diameter of 5mm as the supporting substrate 2 After 3 minutes of treatment in the photocatalytic strong oxidation reactor of the photocatalyst, protozoa, algae and bacteria were detected, and the results were not detected, and the killing rate reached 100%. The ballast water treated by the 3-day bacterial culture method was less than No bacteria with a thickness of 50 μm has been detected, which proves that the method of the present invention can completely kill the spores; meanwhile, the COD of ballasted seawater is reduced to 0.08 mg / L, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com