Blast-furnace slag processing system

A treatment system and technology for blast furnace slag, which is applied in the field of metallurgical ironmaking equipment, can solve the problems of high energy consumption for long-distance transportation of slag-water mixture, difficulties in maintenance of bottom filter tanks, large floor area of advection tanks, etc., and achieve equipment and facilities Simplicity, improved system reliability, and high slag flushing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

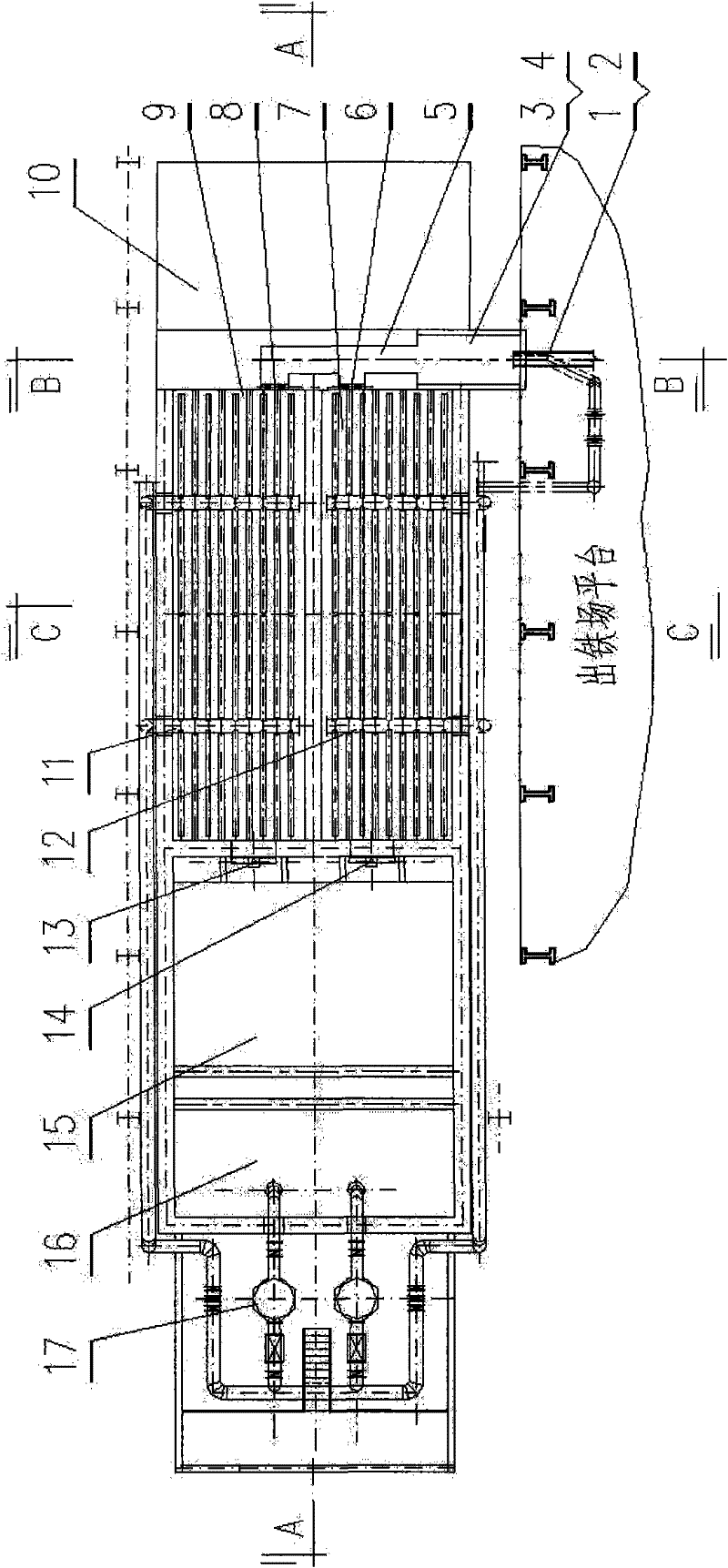

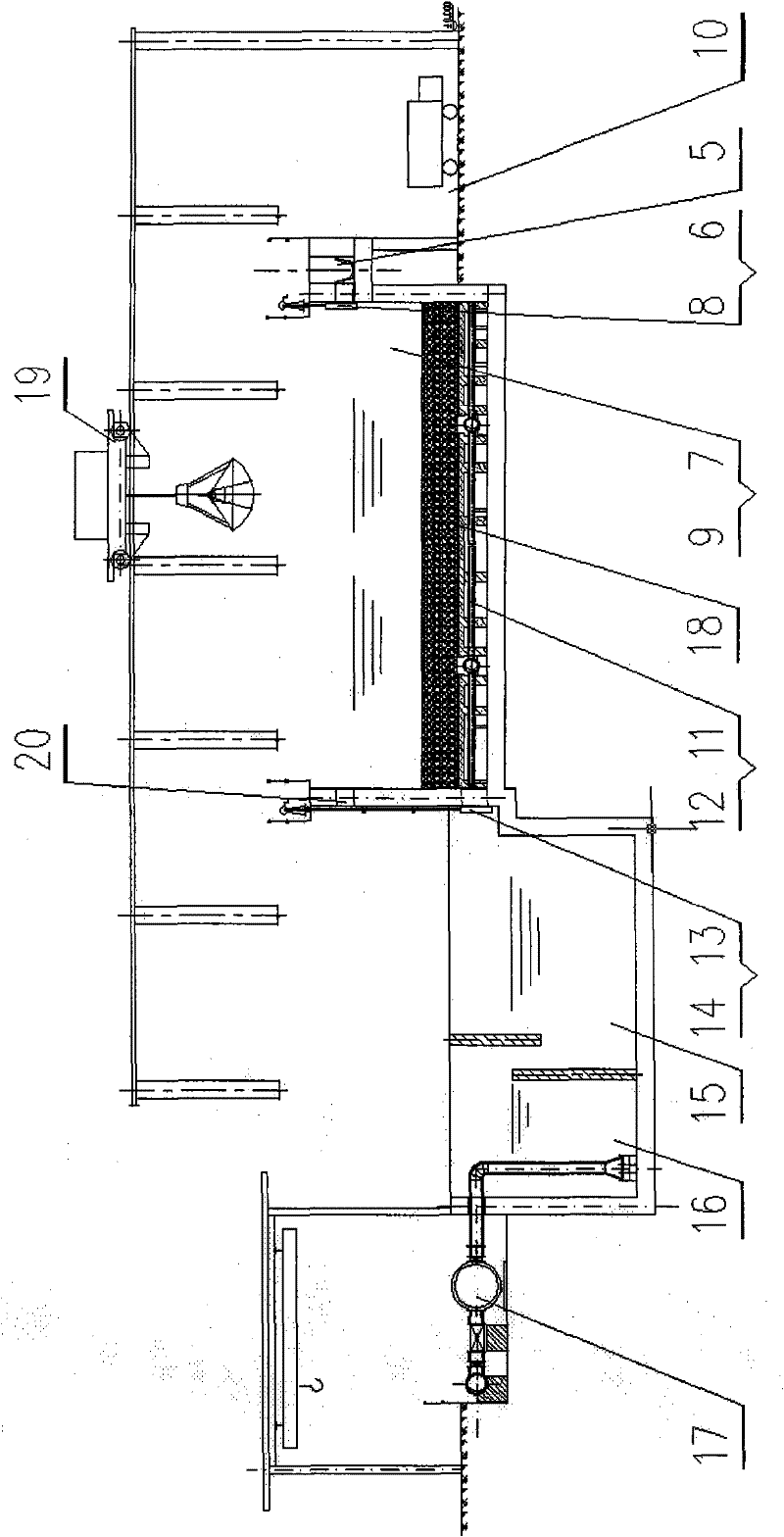

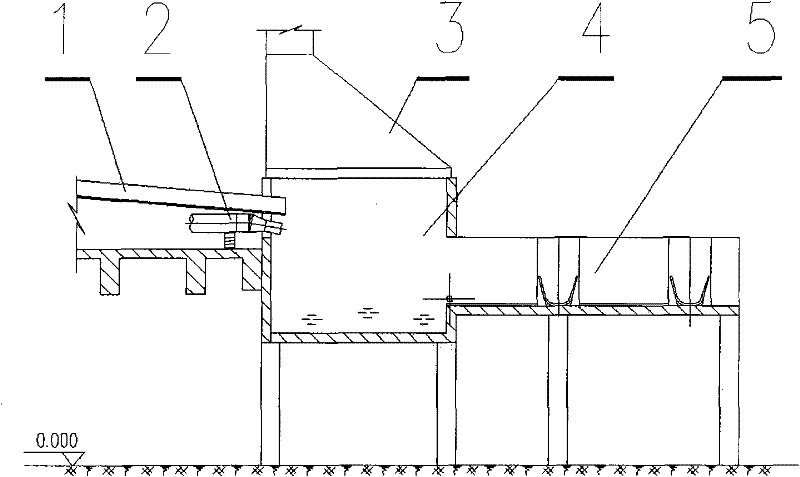

[0030] Attached below Figure 1~4 The specific embodiment of the present invention is described in further detail:

[0031] In the present invention, in the narrow and long free space on the side of the casthouse, the bottom filter group is arranged close to the casthouse and above the ground level, and an advection pool and a circulation pool are arranged in series behind the bottom filter group, and the advection pool and circulating pools are located below ground level.

[0032] The slag ditch 1 and the punching box 2 of the blast furnace slag treatment system are connected with the slag flushing tank 4, the slag flushing tank 4 is connected with the steam chimney 3, and the water slag ditch 5, and the water slag ditch 5 passes through the slurry valve 6, the slurry valve 8, They are respectively connected with the bottom filter tanks 7 and 9; the bottom side of the bottom filter tanks 7 and 9 are provided with outlet holes, and are connected with the advection tank 15 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com