Process for producing insulating rectangular stay of transformer

A production process and transformer technology, which is applied in transformer/inductor parts, inductance/transformer/magnet manufacturing, textiles and papermaking, etc. It can solve the problems of affecting the withstand voltage performance of transformers, reducing the purity of insulating parts, and complex processing technology. Achieve the effect of improving the quality and safety guarantee factor, reducing the processing procedures, and high fiber purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

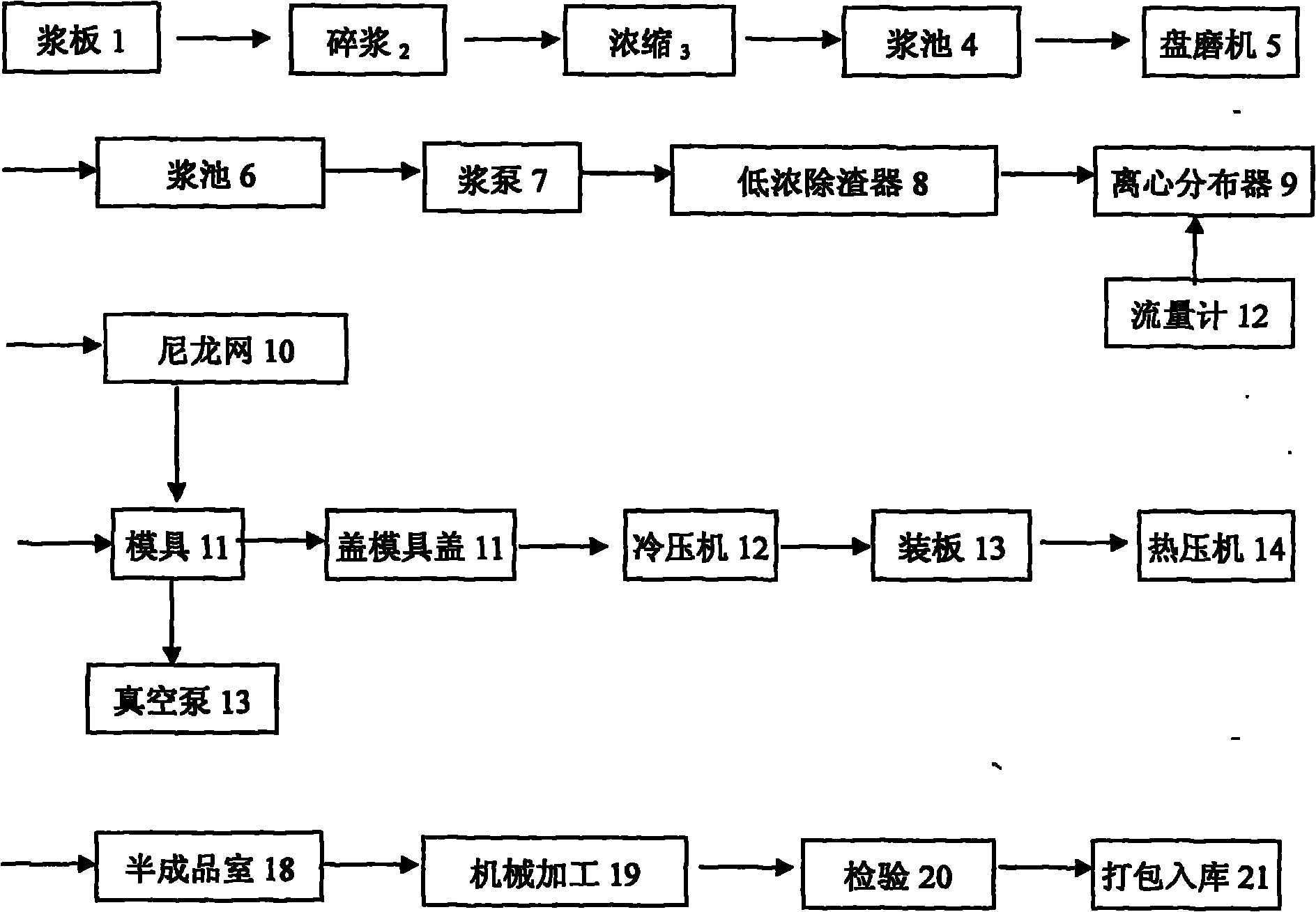

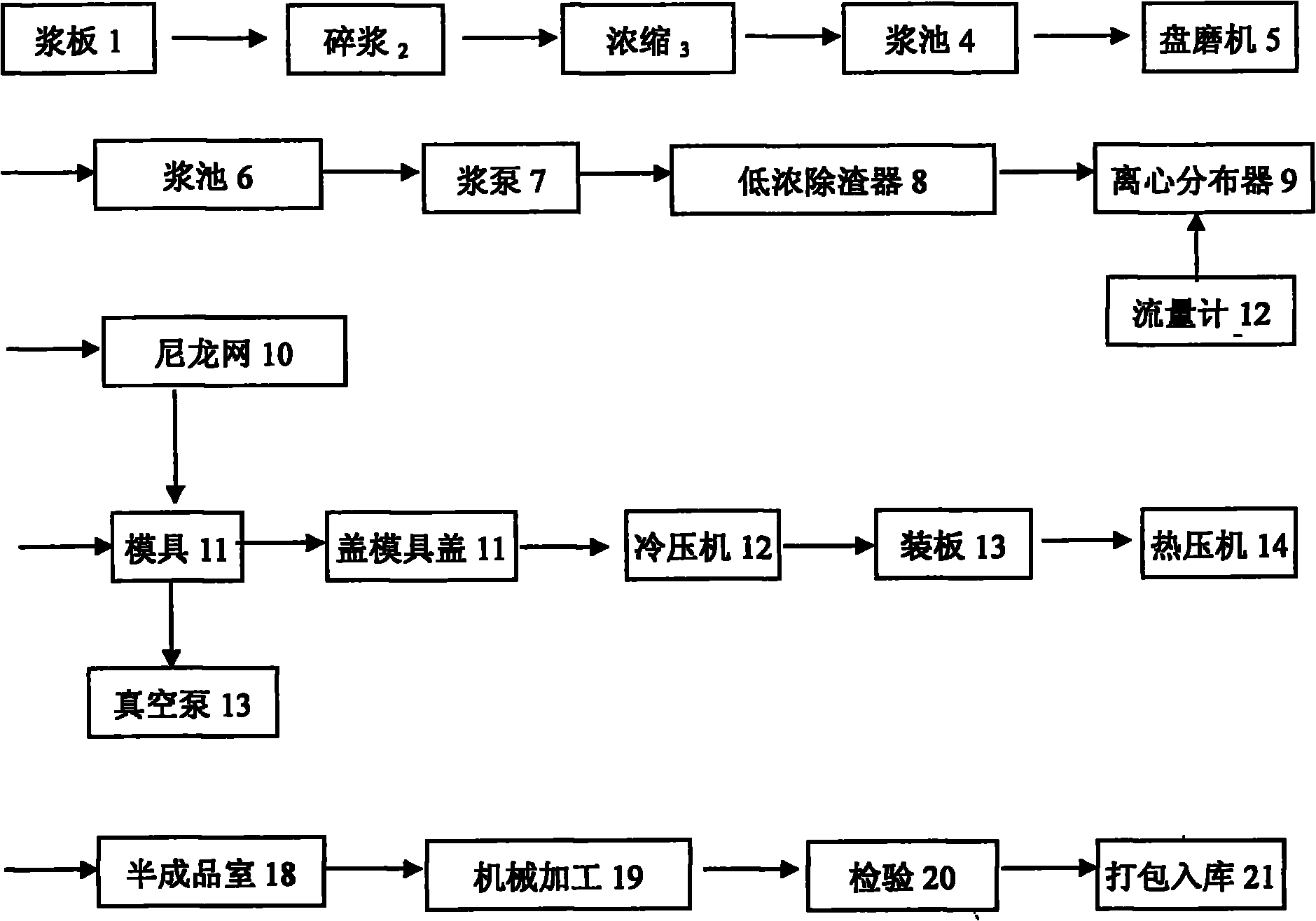

[0012] Crumble the pulp plate (1) into pulp (2) concentrate (3) put it into the pulp tank (4), and disc refiner (5) grind the pulp to a degree of knocking of 34±1°SR and a wet weight of 14±1g to the pulp tank (6), use the pump (7) to dilute the ground slurry to a concentration of 0.3 ± 0.05%, and then go to the centrifugal distributor (9) after the low-concentration slag remover (8) removes the slag, and the centrifugal distributor removes the slurry Distribute in the mold (11) that adjusts dividing plate size, mold bottom plate, dividing plate and inner wall all lining good 40-50 mesh nylon mesh (10). When the amount of material displayed by the flowmeter (12) on the centrifugal distributor reaches the requirement, the slurry pump stops automatically. When the centrifugal distributor works, the vacuum pump (13) starts to vacuumize. When the slurry pump stops, the vacuum pump continues to vacuumize for 10-15 minutes and then stops. Cover ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap