In vitro method for the determination of glycemic index of food products

A technology of glycemic index and food, applied in the direction of biological testing, material inspection products, etc., can solve problems such as inability to classify, and achieve the effects of saving time and cost, improving accuracy and precision, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

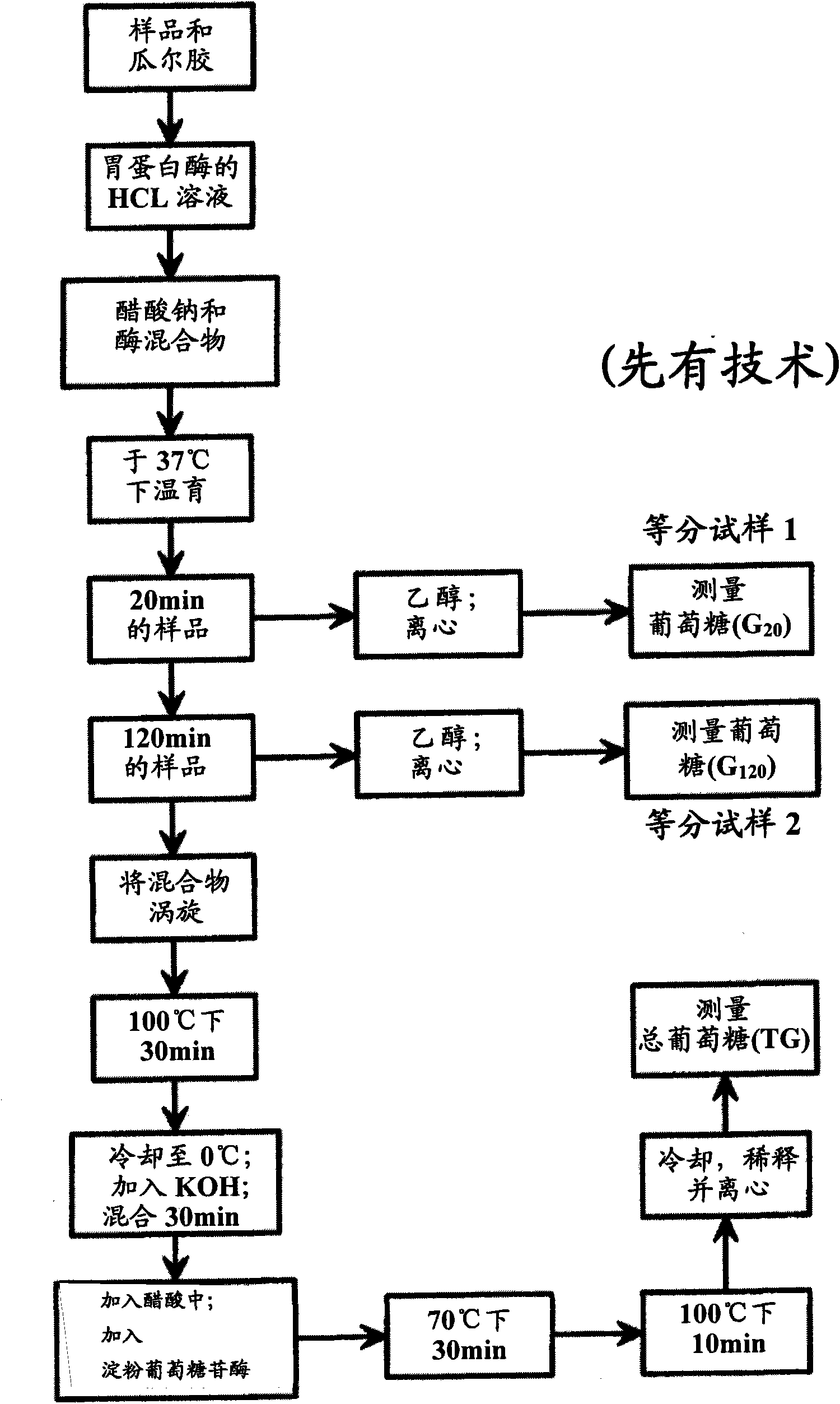

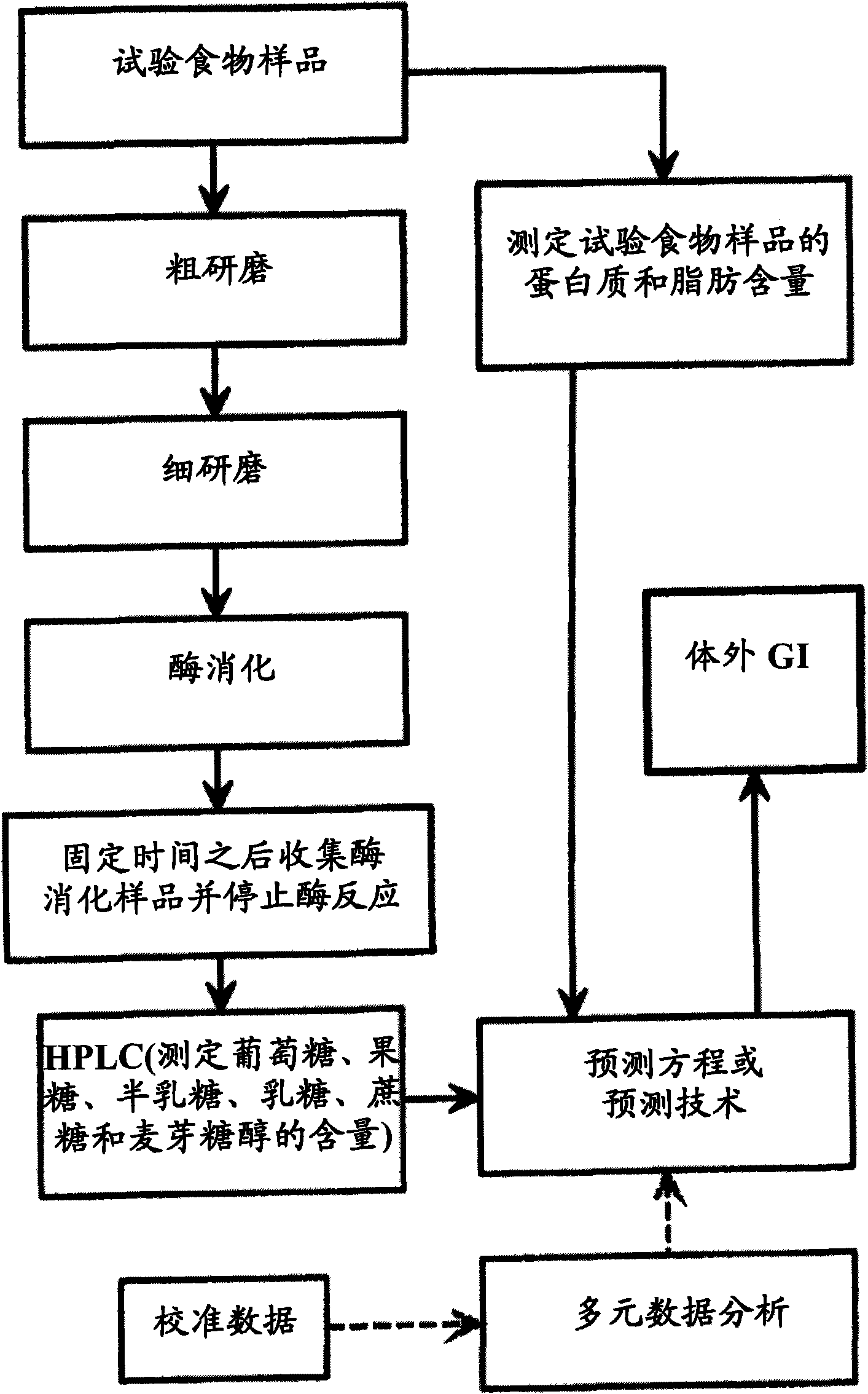

Method used

Image

Examples

Embodiment 1

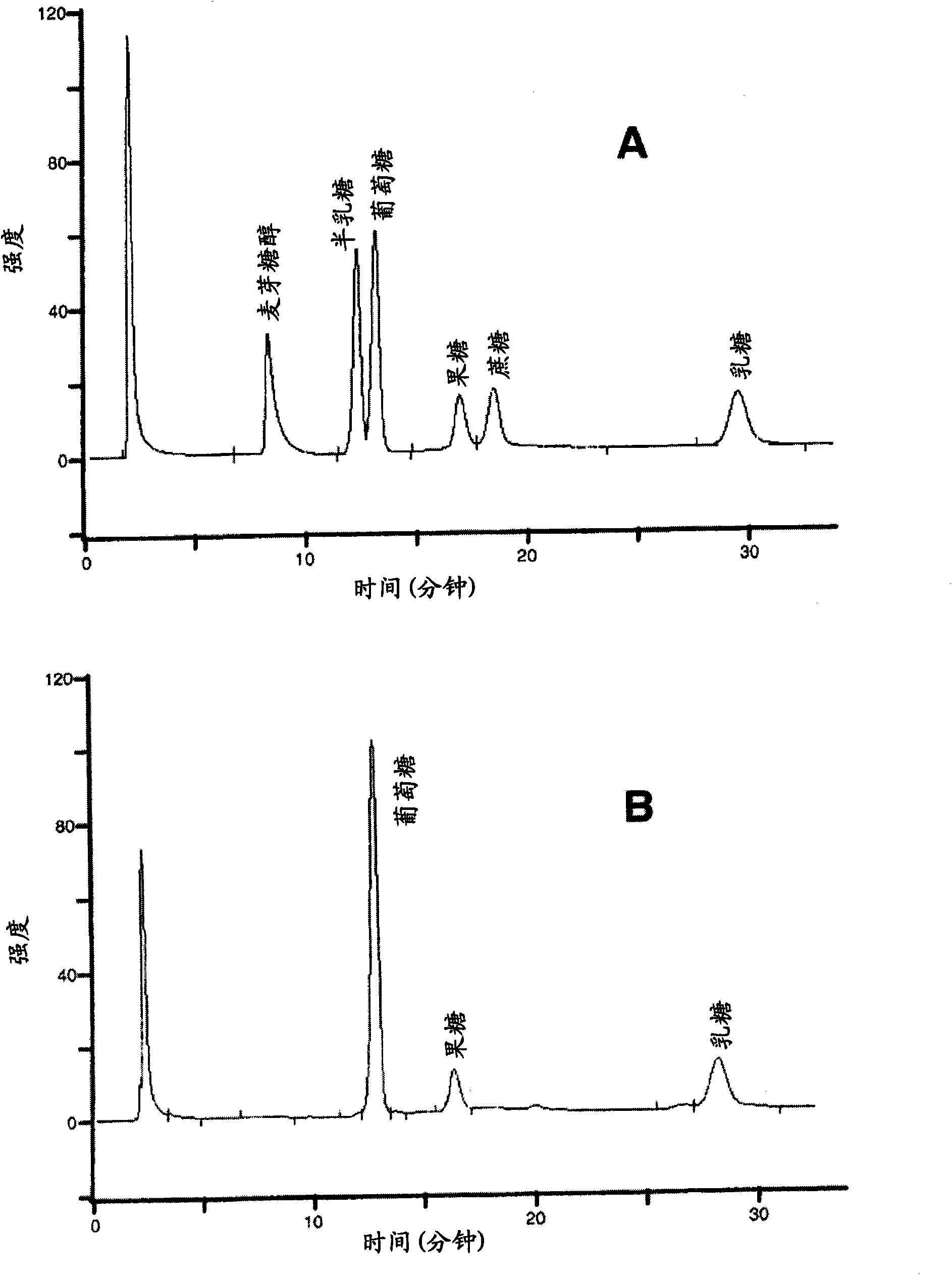

[0045] Example 1 . For the determination of the glycemic index in vitro of the present invention, for the calibration of the method and the determination of unknown samples, this example provides a detailed analysis scheme. In all cases where specific equipment, reagents and / or specific methods and operating parameters are suggested, it will be understood that equivalent equipment, reagents and / or specific methods and operating parameters can be used.

[0046] Instrument: 1. Temperature-controlled oscillating water bath (capable of about 175 strokes / min); 2. Vortex mixer; 3. Analytical balance (accurate to ±0.0001g); 4. Measuring bottle, class A, 100ml, 1000ml; 5 . Pipettes, Class A, 1ml, 2ml, 5ml, 6ml, 10ml; 6. Glass bulbs, 6mm (Fisher #11-312-D or equivalent); 7. Glass sample vials (40ml) with screw caps ( VWR #66014-389 or equivalent); 8. Plastic centrifuge tube (50ml) with screw cap (VWR #21008-730 or equivalent); 9. Centrifuge; 10. Spex CertiPrep 6850 Refrigerated Grind...

Embodiment 2

[0079] Example 2. Examine a large number of commercially available food and other food samples using in vivo and in vitro protocols. The majority (25 / 34) of the in vivo glycemic index values were determined using an in vivo test performed by a reputable, well respected, experienced private laboratory; the remainder of these in vivo glycemic index values were taken from scientific literature. These same samples were also examined using the in vitro method of the invention described in Example 1. These data were then used to calculate the model parameters for the in vitro glycemic index assay described in the text, using the MLR, PLS, and neural network methods available in JMP Statistical Software.

[0080] After the parent application was filed, it was discovered that the HCl solution used to prepare the pepsin / guar solution was 0.5N, not the required 0.05N. Because the pepsin / guar gum solution was used to prepare the enzymatic digestion solution, the pH during enzymat...

Embodiment 3

[0085] Example 3. After the original application was submitted, work continued, adding additional data points, and making some modifications to the method to provide an even more correct and accurate in vitro method. As described above in Example 2, the pH during the enzymatic digestion step in Example 2 was too low. The appropriate pH for the enzymatic digestion step should be around 5; samples were processed in the same manner as in Example 2, except for that modification. Therefore, the 31 samples used in Example 2 were re-run to obtain data at a more optimal enzyme digestion pH. In addition, 34 new samples were added to the rerun samples of Example 2, for a total of 65 samples. This in vitro method (currently at the date of the continuation in part) is based on enzymatically digested samples at an optimal pH and is provided herein. Of course, those skilled in the art will recognize that the accuracy and precision of the method may be increased even further as additiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com