A thermal analysis control method for preparing magnesium oxide crystal electric arc furnace

A control method and electric arc furnace technology, applied in chemical instruments and methods, crystal growth, adaptive control, etc., can solve the problems of poor controllability of crystallization process, restricted crystal yield and quality, temperature field distribution and unknown molten pool shape, etc. , to achieve the effect of deepening understanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

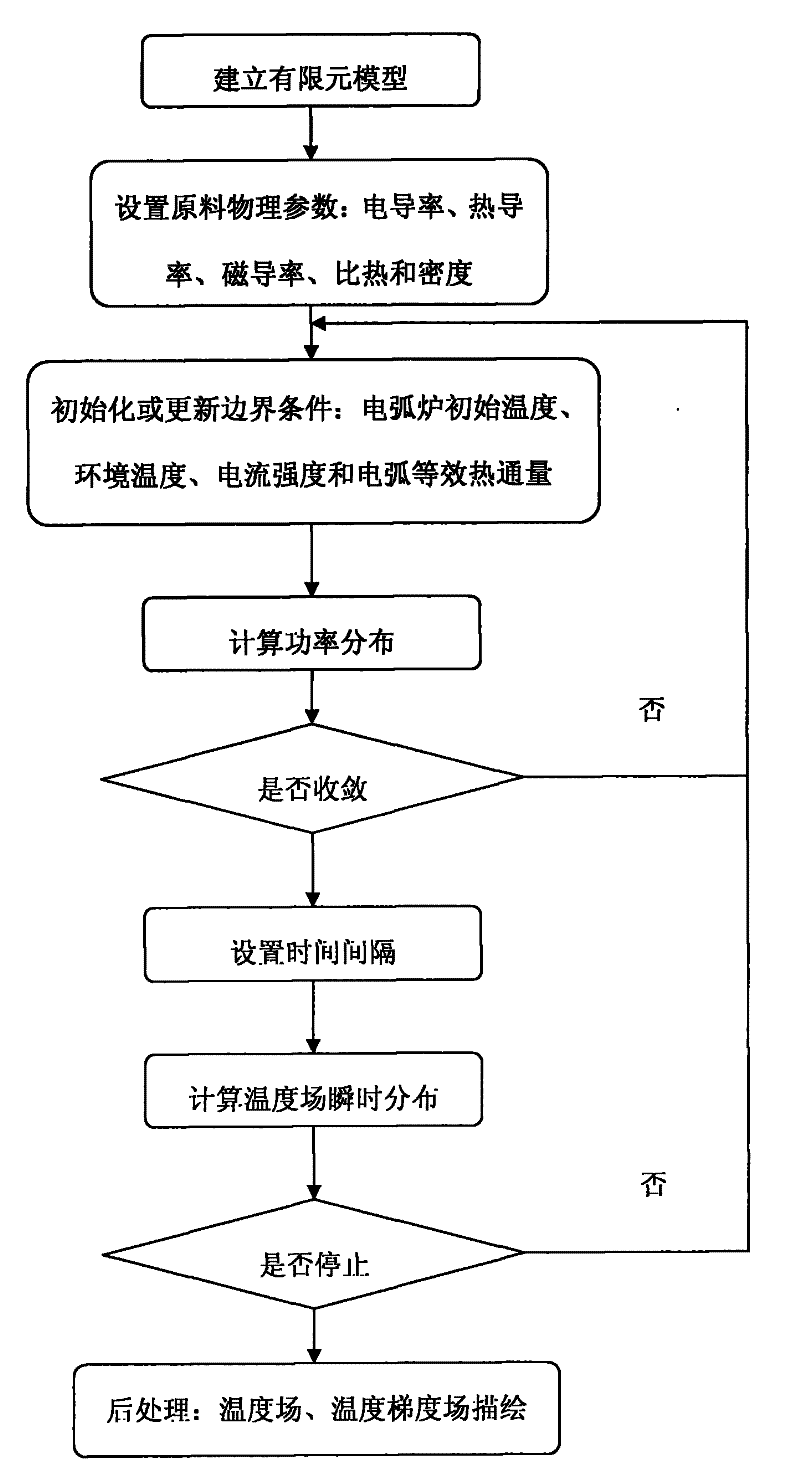

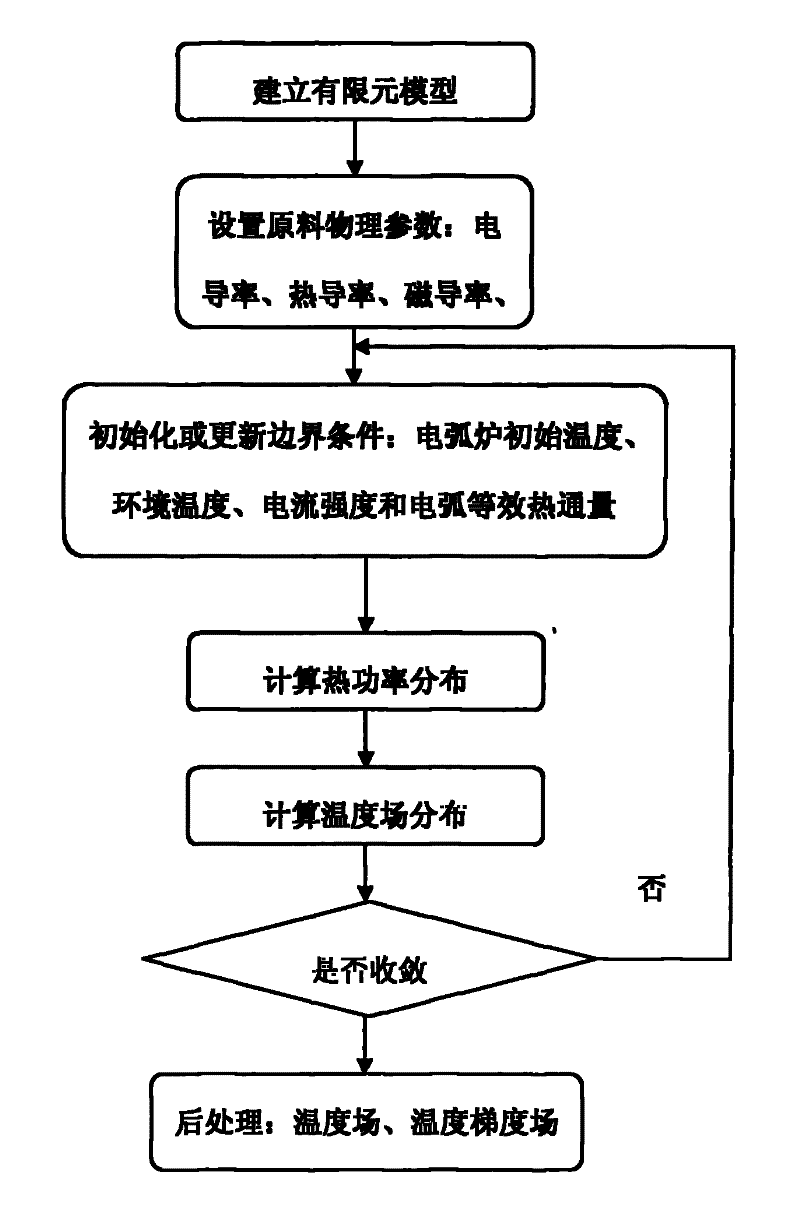

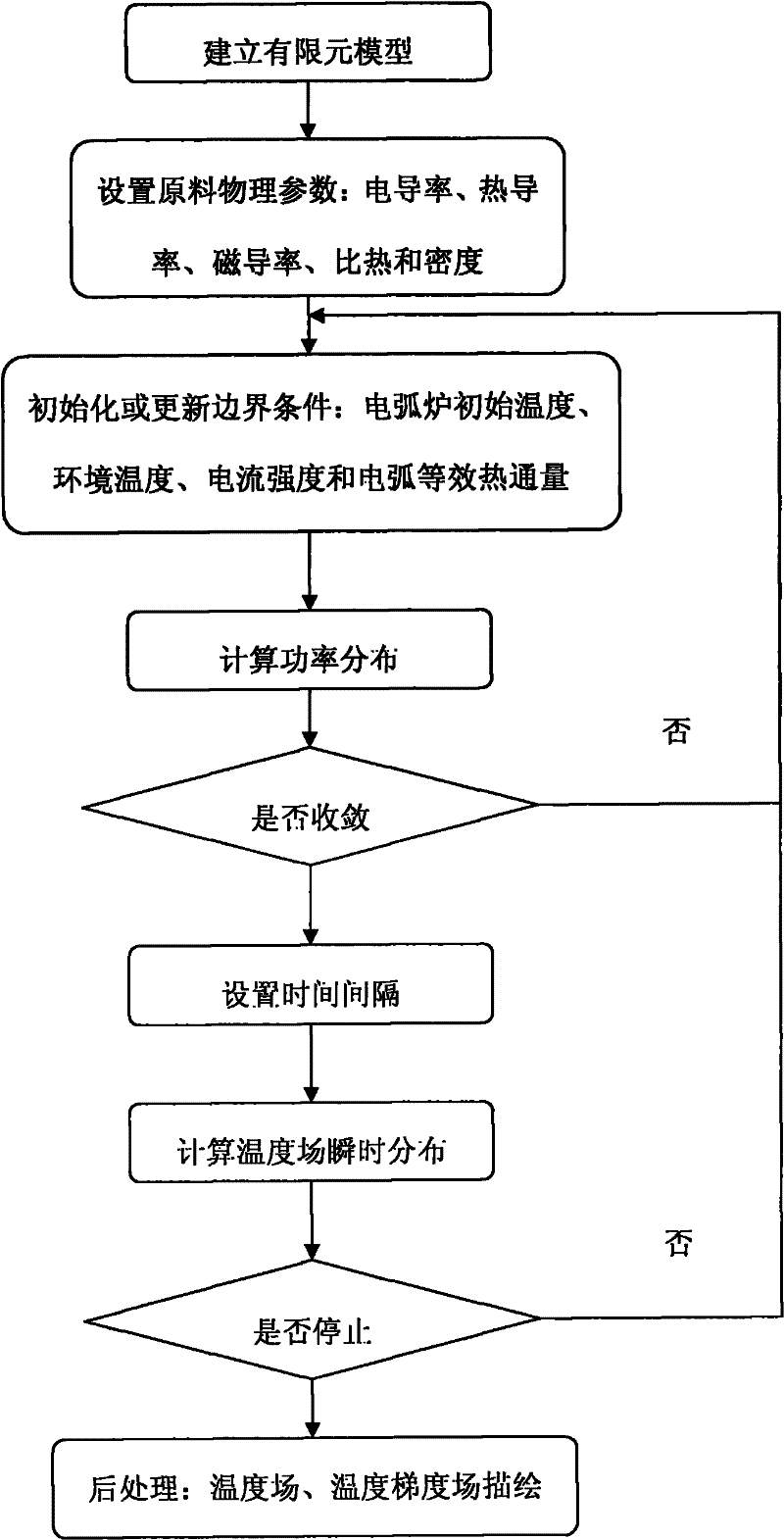

[0012] According to the different process stages of magnesium oxide crystal smelting, transient and steady-state analysis control are two typical control methods. Transient analysis control is adopted in the initial stage of smelting, such as figure 1 shown; the middle or late stage of smelting adopts steady-state analysis control, such as figure 2 shown. The specific implementation steps are as follows:

[0013] Step (1), establishing a three-dimensional finite element model of the electric arc furnace according to the size and relative positions of the electric arc furnace, electrodes and ore powder;

[0014] Step (2), then setting the parameters of the various physical properties of the raw material as a function of temperature, including electrical conductivity, thermal conductivity, magnetic permeability, specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com