Semiconductor rectifying device and manufacturing method thereof

A manufacturing method and technology of rectifying devices, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., to achieve high reliability, reduce forward conduction voltage drop, and optimize source/drain contact areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Embodiment: A kind of manufacturing method of semiconductor rectifier device and obtained device

[0045] as attached Figure 1-9 Shown, a kind of manufacturing method of semiconductor rectifier device, the process is as follows:

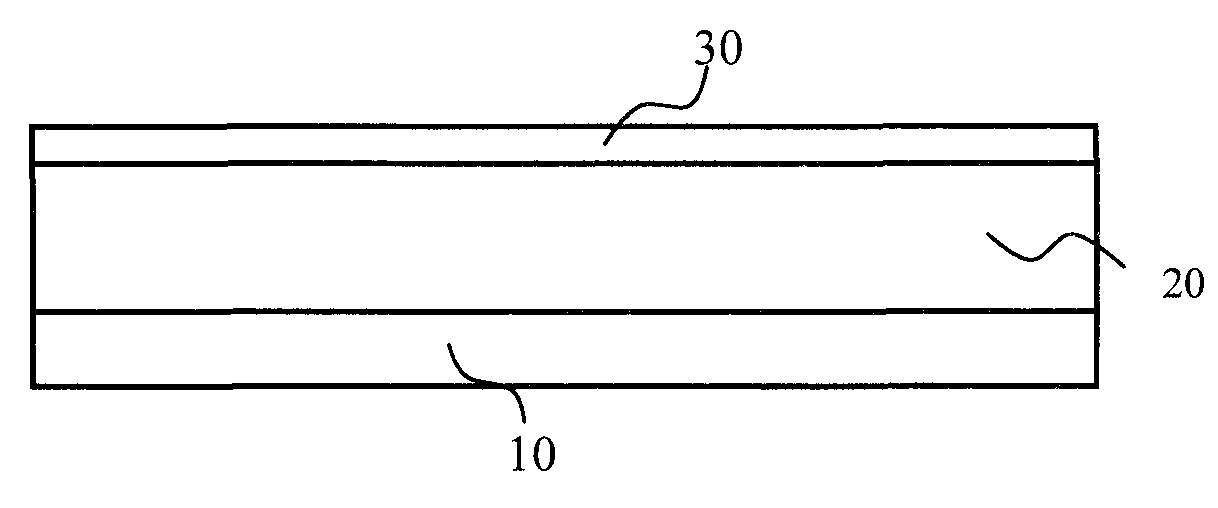

[0046] a) Provide a semiconductor substrate doped with N-type impurities with two opposite main surfaces, the semiconductor substrate consists of an N+ second main surface 10 as a silicon substrate and an N-first main surface 20 as an epitaxial layer composition;

[0047] b) forming a field oxide layer 30 on the surface of the first main surface of the semiconductor substrate;

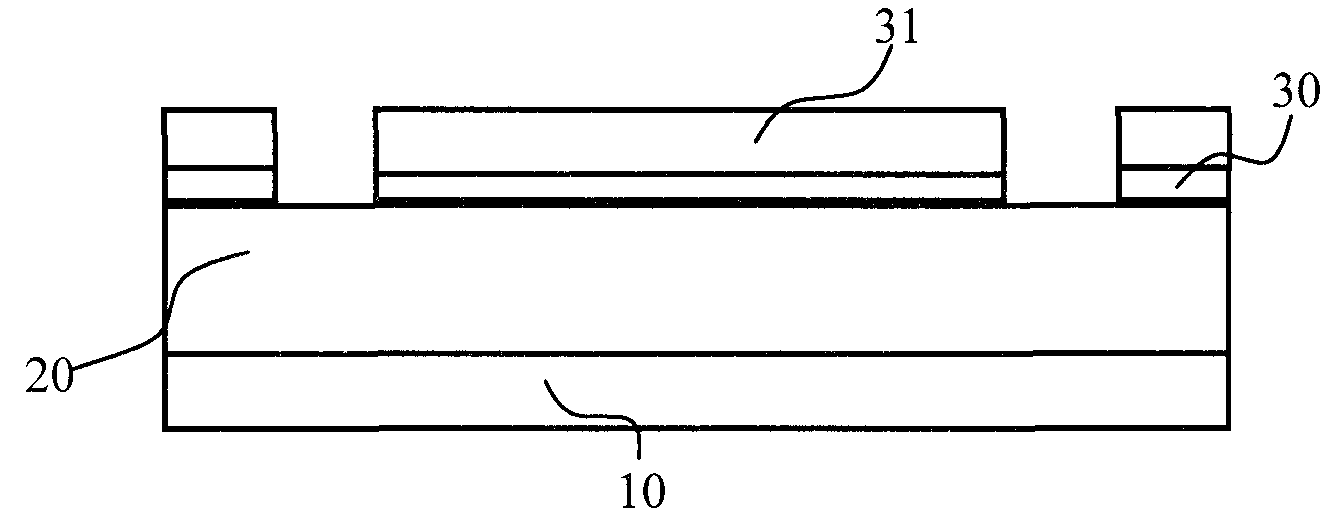

[0048] c) using a photoresist 31 to selectively cover the field oxide layer 30 to etch the field oxide layer in a part of the region;

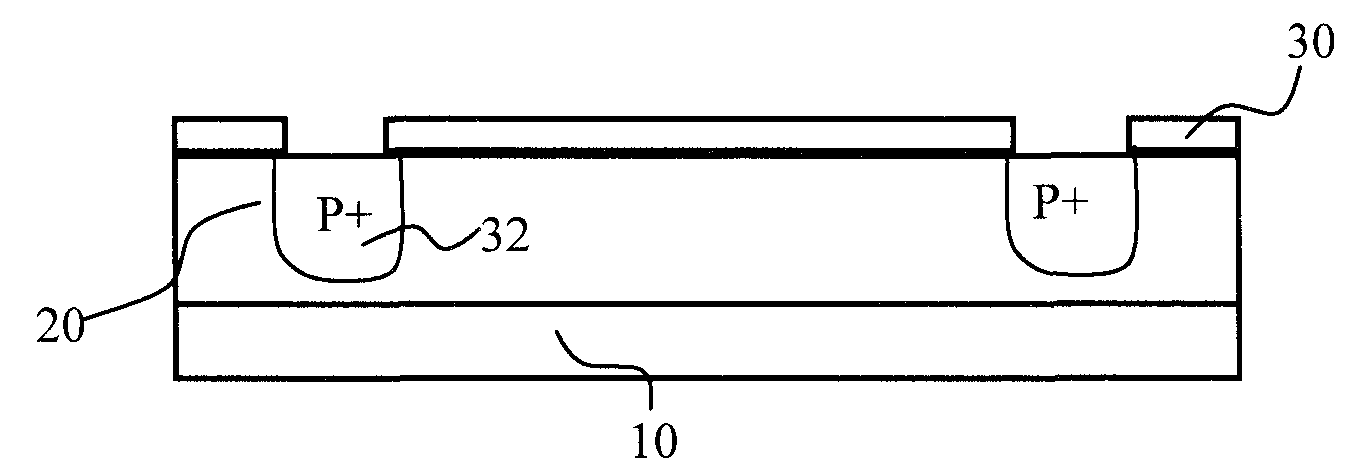

[0049] d) Remove the photoresist layer 31, use the field oxide layer 30 or the photoresist as a mask layer, inject P-type impurities into the N-first main surface, that is, the epitaxial layer 20, and then perform the thermal diffus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com