Method for preparing TiO2 nanocryatal/nanotube composite photocatalyst

A nanotube composite and photocatalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high cost, secondary pollution, etc., and achieve low cost, strong adsorption performance, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

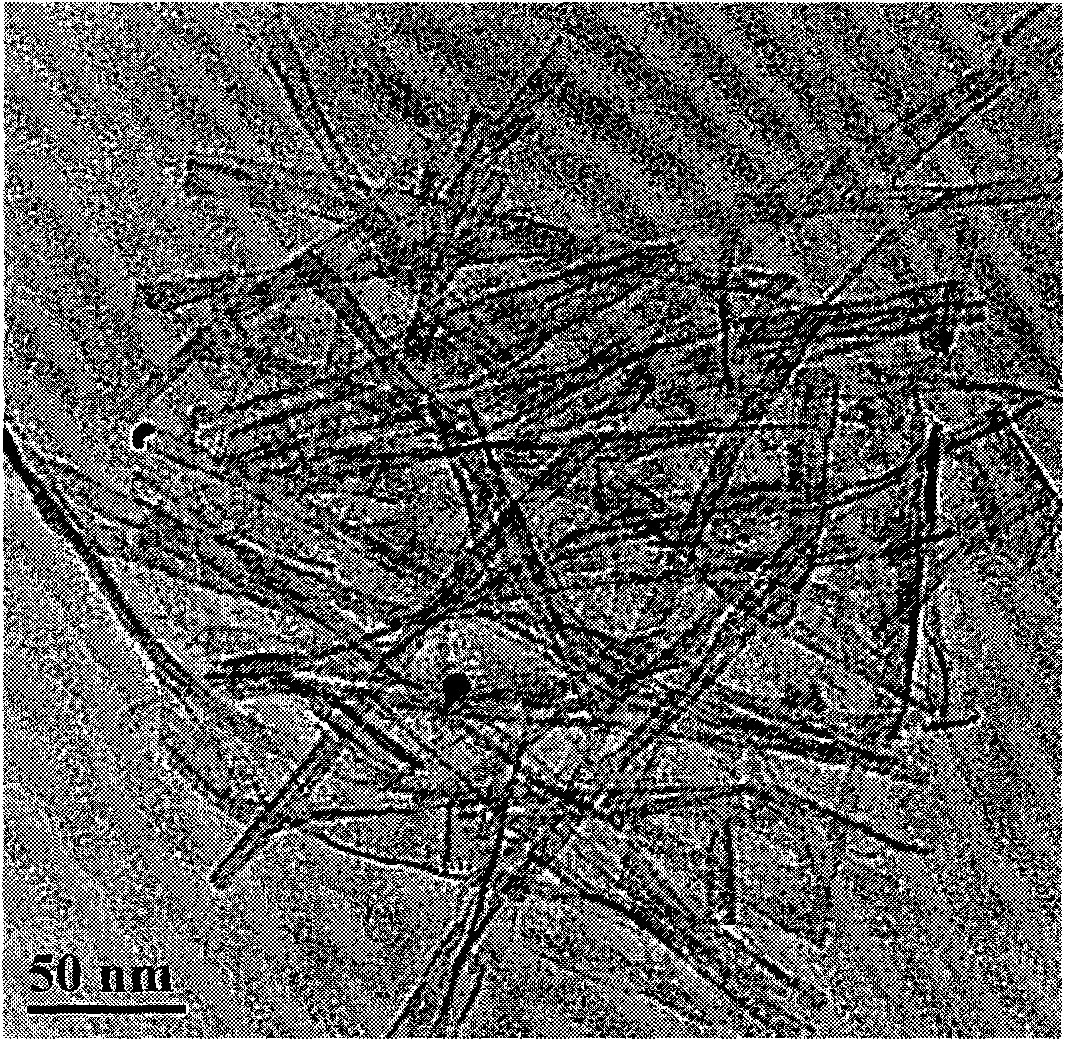

[0026] P25 was used as a raw material to prepare titania nanotubes by hydrothermal synthesis. Weigh 0.1g of P25 into NaOH solution with a concentration of 10mol / L, stir until uniform at room temperature, put the mixed solution into a hydrothermal kettle, and react at 110°C for 20-24 hours. Take out the reactor and cool to room temperature, wash the product with deionized water until the pH is 8-9, and then dissolve it in 0.1mol / L HNO 3 In the solution, sonicate for 30 minutes, centrifuge and wash with water for 3-4 times, and finally wash off the water with alcohol, and dry the product at 75° C. for 24 hours to obtain titanium dioxide nanotubes with uniform morphology. figure 1 The transmission electron microscope picture of the titanium dioxide nanotubes prepared in this example shows that the titanium dioxide nanotubes have a diameter of 5-8 nm and a length of 100-200 nm.

Embodiment 2

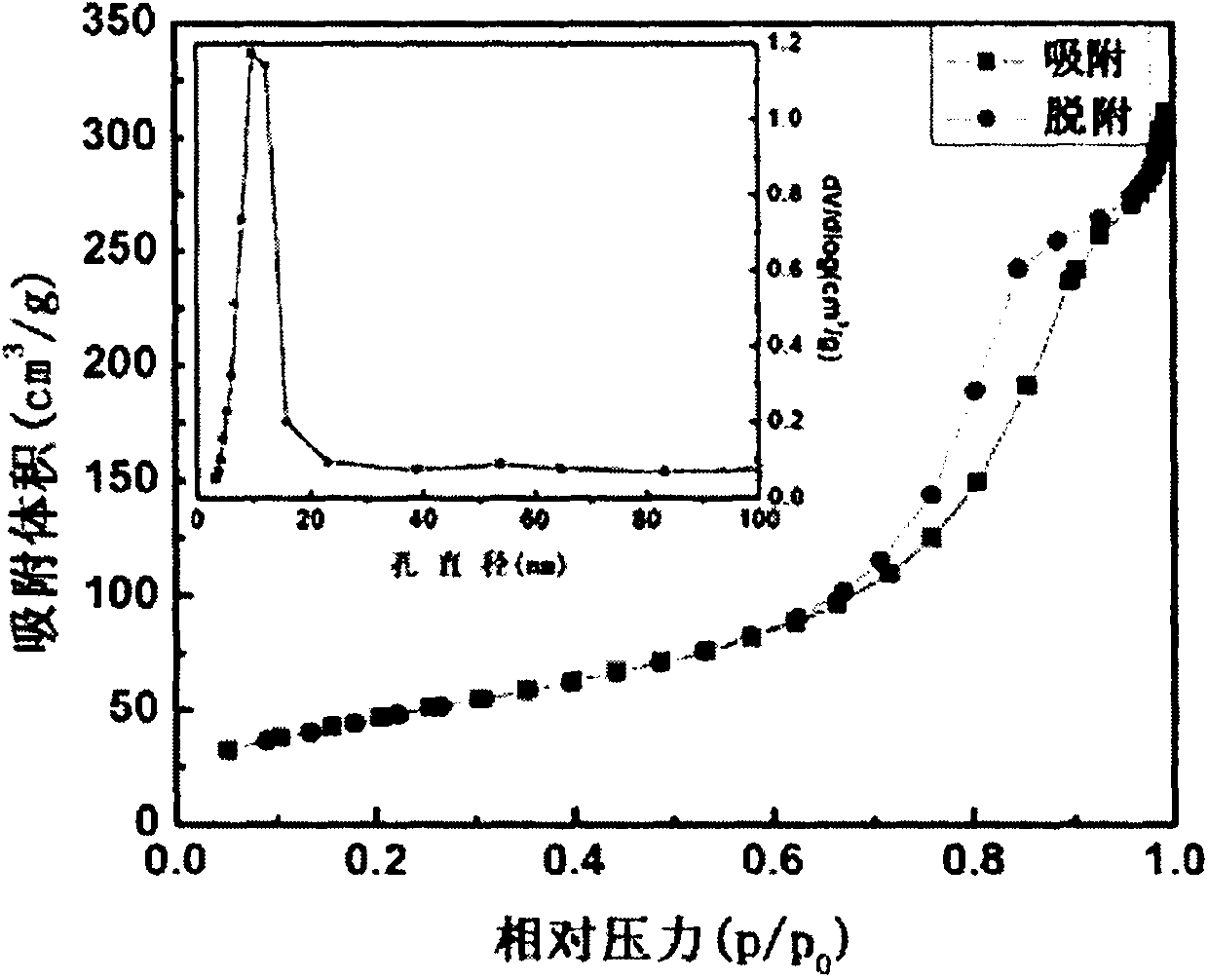

[0028] Add 0.1 mL of butyl titanate to 8 mL of absolute ethanol, stir for 2 minutes, take 0.1 g of titanium dioxide nanotubes prepared by hydrothermal synthesis, dissolve them in lower alcohol, and ultrasonicate and stir for 2 minutes each. The solution containing titanium dioxide nanotubes is poured into a crucible, and placed on top of a sealable container. The bottom of the sealable container is prefilled with 3 mL of distilled water. After sealing the container, put it into an oven, start heating to 120°C, the heating rate is 10-20°C / min, and keep warm for 10-12 hours after the temperature reaches the set temperature. Cool down to room temperature naturally after heat preservation, open the airtight container, take out the crucible, pour out the powder, wash with distilled water and absolute alcohol three times respectively, and dry in vacuum at 75°C for 12 hours. figure 2 Preparation of surface loaded TiO for this example 2 Nanocrystalline TiO2 Nanotube Composite Photo...

Embodiment 3

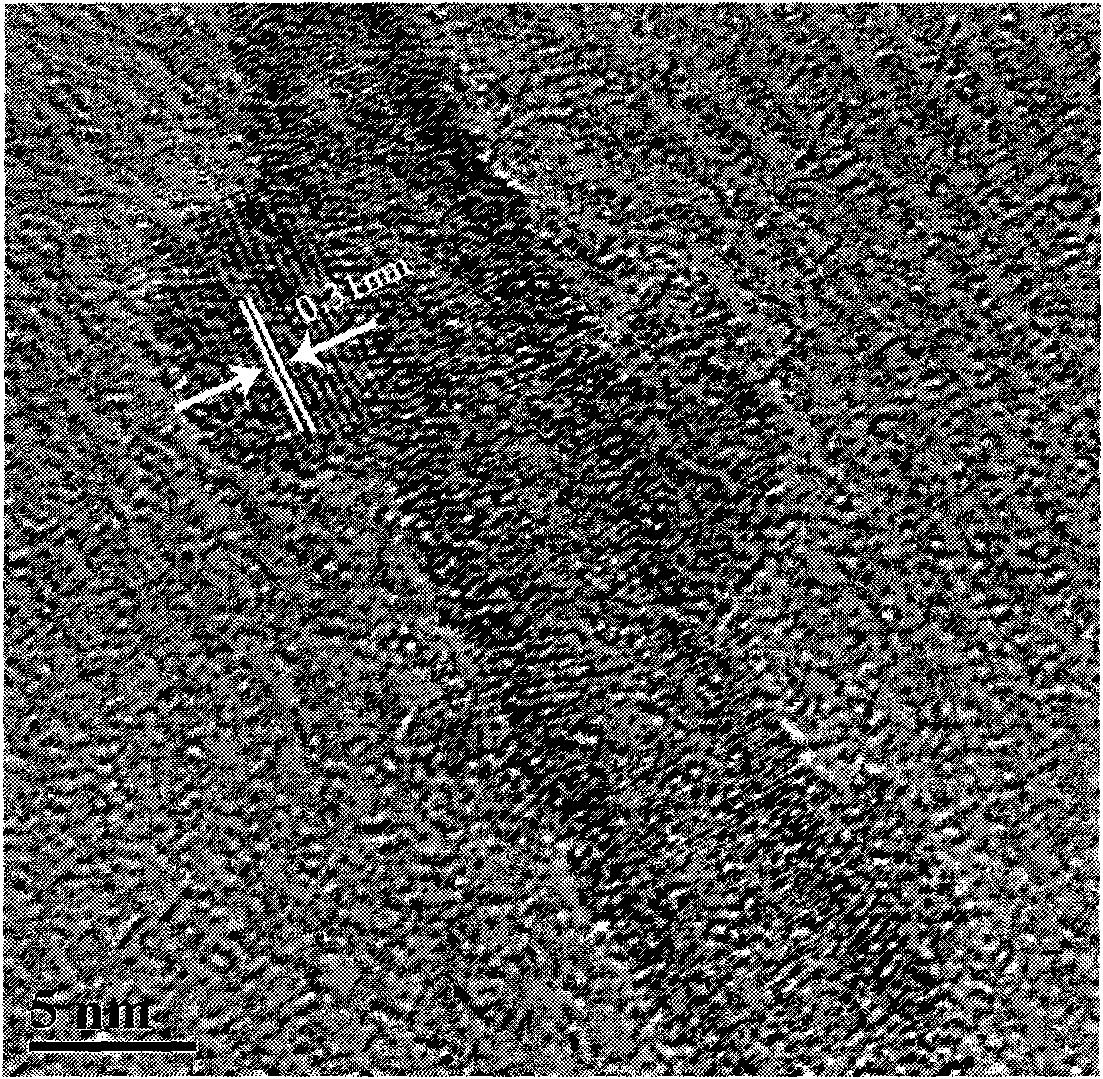

[0030] Add 0.15 mL of butyl titanate to 8 mL of absolute ethanol, stir for 2 minutes, take 0.1 g of titanium dioxide nanotubes prepared by hydrothermal synthesis, dissolve them in lower alcohol, and ultrasonicate and stir for 2 minutes each. The solution containing titanium dioxide nanotubes is poured into a crucible, and placed on top of a sealable container. The bottom of the sealable container is prefilled with 3 mL of distilled water. After sealing the container, put it into an oven, start heating to 150°C, the heating rate is 10-20°C / min, and keep warm for 10-12 hours after the temperature reaches the set temperature. Cool down to room temperature naturally after heat preservation, open the airtight container, take out the crucible, pour out the powder, wash with distilled water and absolute alcohol three times respectively, and dry in vacuum at 75°C for 12 hours. image 3 Preparation of surface loaded TiO for this example 2 High-resolution transmission electron microsc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com