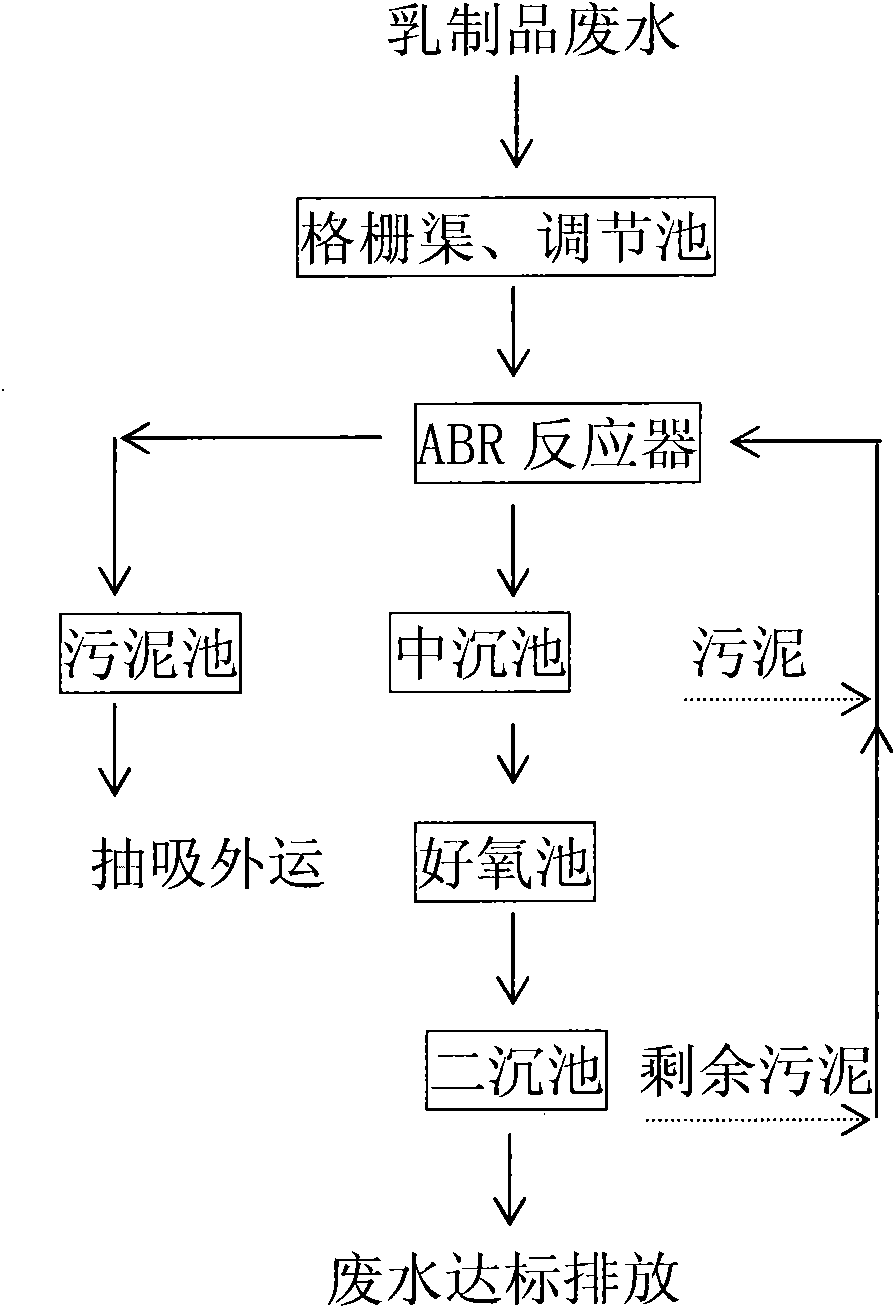

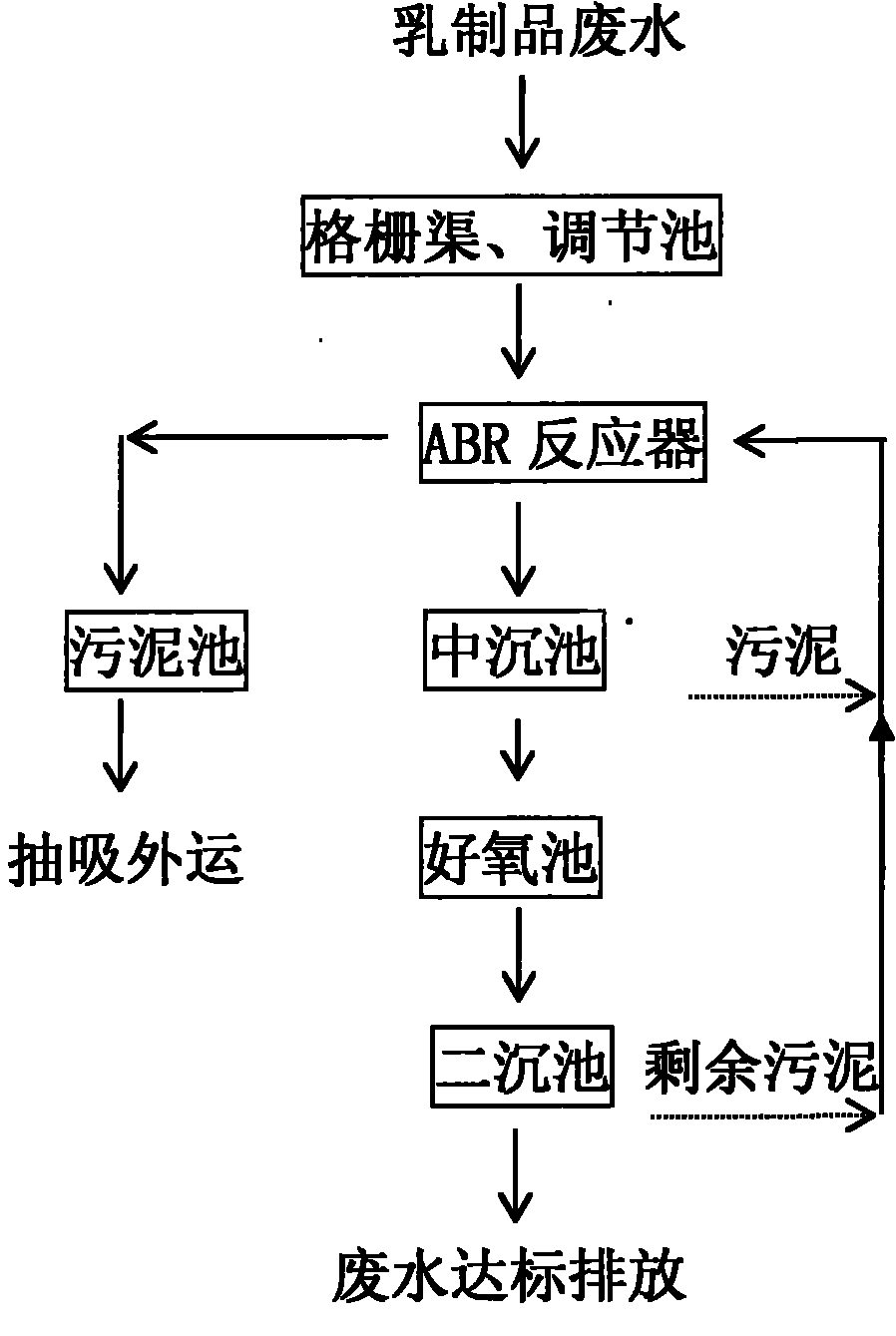

Treatment process of waste water of dairy products

A dairy wastewater treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of large sludge discharge, difficulty in system operation, Long residence time and other problems, to achieve the effect of small sludge discharge, high treatment efficiency and reduced discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In dairy wastewater, suspended solids (SS), chemical oxygen demand (COD Cr ), biochemical oxygen demand (BOD 5 ), ammonia nitrogen (NH 3 The mass concentrations of -N) are 300-1000mg / L, 800-3000mg / L, 350-1500mg / L, 25-70mg / L, respectively;

[0028] a. First, the dairy waste water is passed through the grid channel to remove the floating matter in the waste water, and then the preliminary treatment of the homogeneous water quality and quantity is carried out through the regulating tank;

[0029] b. Then pump the preliminarily treated wastewater into the ABR reactor for degradation, and remove SS, COD, BOD, and NH in the wastewater through the ABR reactor 3 -N, a small amount of sludge discharged from the ABR reactor is discharged into the sludge tank, and then the sludge is sucked out for treatment;

[0030] c. Discharge the waste water degraded by the ABR reactor into the middle sedimentation tank for solid and liquid separation to remove COD, BOD and NH in the waste ...

Embodiment 2

[0035] In dairy wastewater, suspended solids (SS), chemical oxygen demand (COD Cr ), biochemical oxygen demand (BOD 5 ), ammonia nitrogen (NH 3 The mass concentration of -N) is respectively 600mg / L, 2500mg / L, 1500mg / L, 25mg / L;

[0036] a. First, the dairy waste water is passed through the grid channel to remove the floating matter in the waste water, and then the preliminary treatment of the homogeneous water quality and quantity is carried out through the regulating tank;

[0037] b. Then pump the preliminarily treated wastewater into the ABR reactor for degradation, and remove SS, COD, BOD, and NH in the wastewater through the ABR reactor 3 -N, a small amount of sludge discharged from the ABR reactor is discharged into the sludge tank, and then the sludge is sucked out for treatment;

[0038] c. Discharge the waste water degraded by the ABR reactor into the middle sedimentation tank for solid and liquid separation to remove COD, BOD and NH in the waste water 3 -N, the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com