Optical sensor of novel high-output all-semiconductor dust particle counter

A particle counter and optical sensor technology, applied in the field of optical sensors, can solve the problems of short service life of photomultiplier tubes, unfavorable miniaturization of optical sensors, and affecting the signal-to-noise ratio of instruments, so as to increase counting efficiency and particle size resolution, and benefit Test the effect of optimal adjustment and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

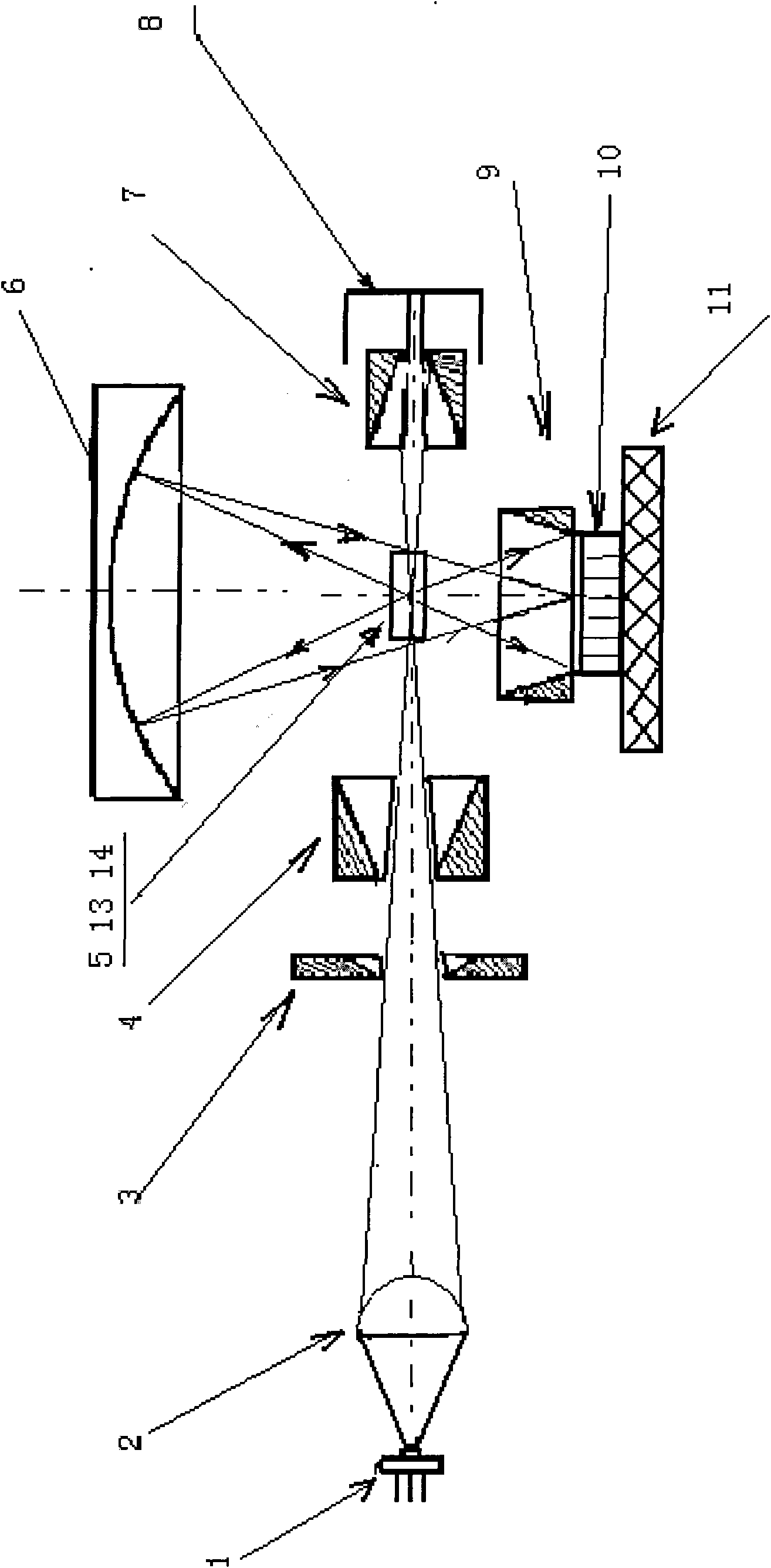

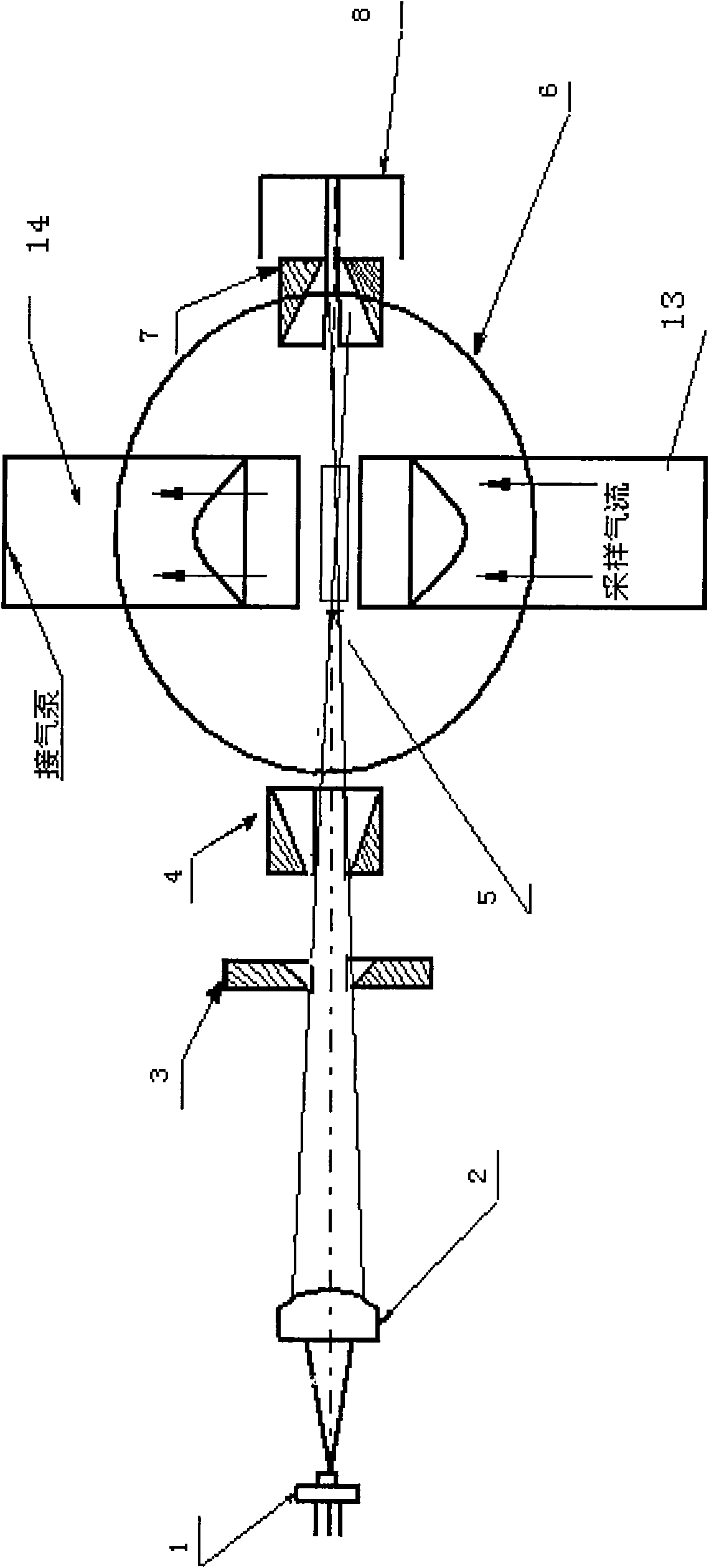

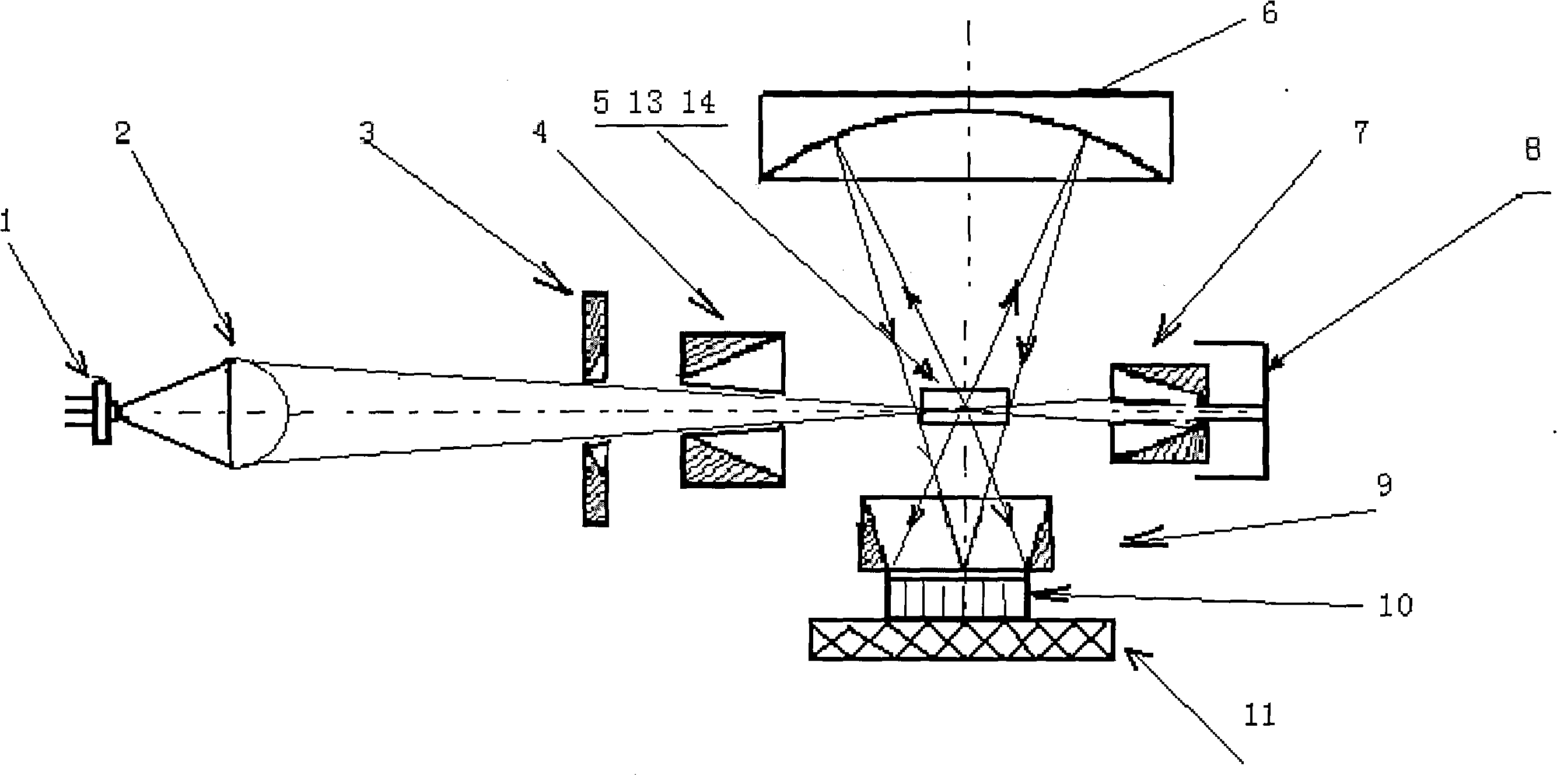

[0010] to combine figure 1 , figure 2 It can be seen that the optical sensor of the new large-flow all-semiconductor dust particle counter of the present invention is a right-angle scattering optical system, including an illumination system, a scattered light collection system, an air system and a pre-adjustable amplifier circuit. The illumination system consists of a semiconductor laser 1, an aspheric mirror 2, a first entrance aperture 3, a second entrance aperture 4, an exit aperture 7, and an optical trap 8. The first entrance aperture 3 and the second entrance aperture 4 are placed on In front of the photosensitive area 5, the exit diaphragm 7 is placed behind the photosensitive area 5; the light source 1 adopts a high-power semiconductor laser light source greater than or equal to 100mW, and the divergent beam is emitted two-dimensionally focused by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com