Preparation method of graphene complex based humidity sensor

A humidity sensor and composite technology, applied in the field of nanomaterials, can solve the problem that the graphene humidity sensor has not been reported, and achieve the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Dilute the concentration of polyvinylpyrrolidone-graphene composite aqueous solution made in the laboratory to 0.02mg / ml, and spread the composite on the surface of silicon oxide / silicon base in the form of a single-layer film by spin coating.

[0021] 2. A gold electrode with a thickness of 80nm is plated on the half surface of the monolayer film.

[0022] 3. Imaging in CAFM mode and determining the position of the measured sample.

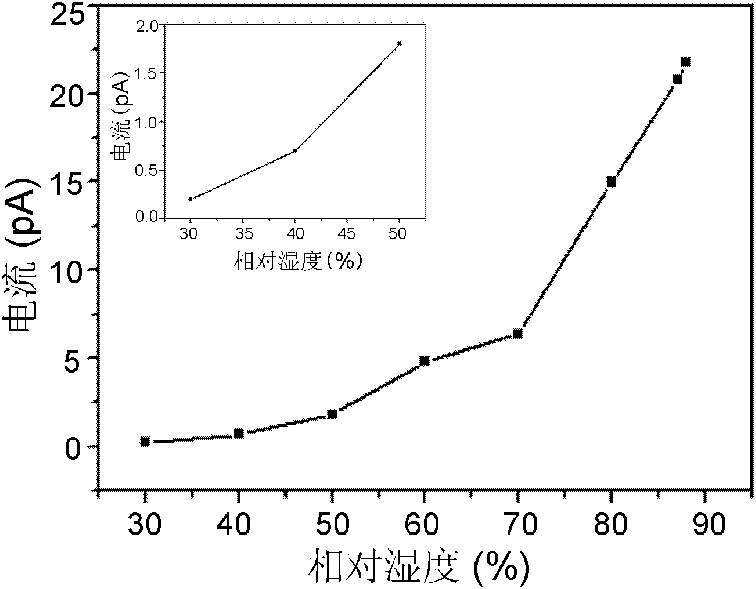

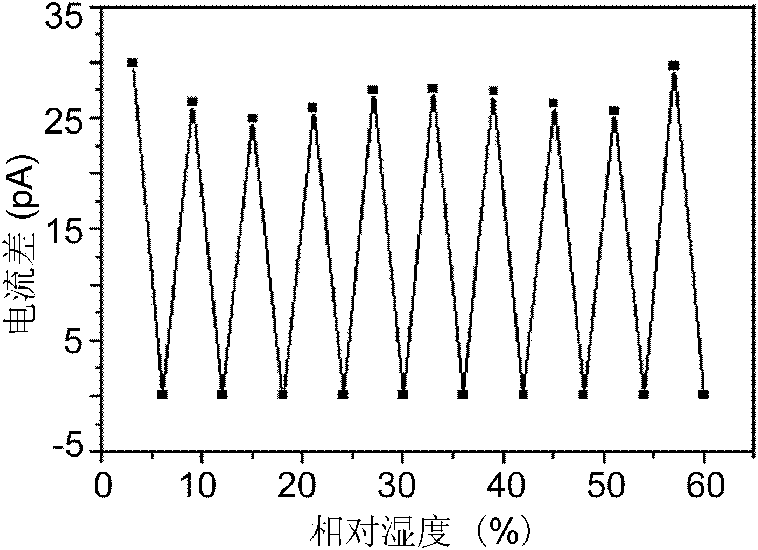

[0023] 4. Adjust the relative humidity of the surrounding environment to 30%, 40%, 50%, 60%, 70%, 80%, and 90%, respectively, apply a bias voltage of 8V to the tested point through the probe, and perform I-V under different humidity curve measurement.

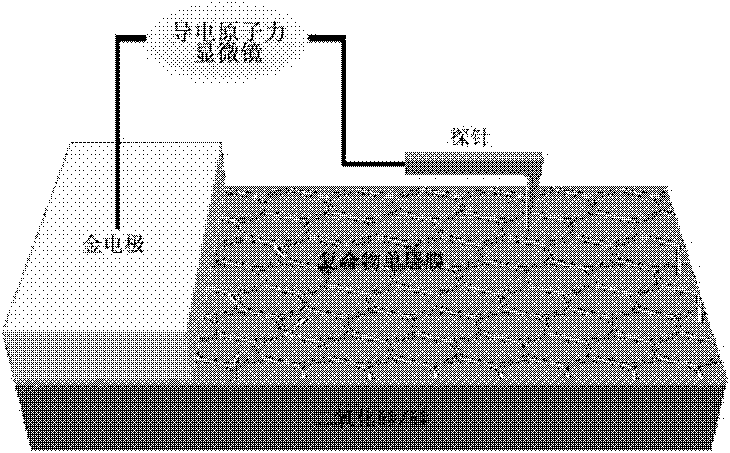

[0024] Such as figure 1 As shown, it is a schematic diagram of the sensor prepared in this embodiment, wherein: a gold electrode and a polyvinylpyrrolidone-graphene conductive film are used as two electrodes respectively, and after imaging based on the contact mode of the atomic force ...

Embodiment 2

[0028] 1. Dilute the concentration of polyvinylpyrrolidone-graphene composite aqueous solution made in the laboratory to 0.01mg / ml, and spread the composite on the surface of silicon oxide / silicon base in the form of a single-layer film by spin coating.

[0029] 2. Plating a layer of silver electrode with a thickness of 50nm on the half surface of the monolayer film.

[0030] 3. Imaging in CAFM mode and determining the position of the measured sample.

[0031] 4. Adjust the relative humidity of the surrounding environment to 30%, 40%, 50%, 60%, 70%, 80%, and 90%, apply a bias voltage of 1V to the tested point through the probe, and perform I-V curves under different humidity Measurement.

Embodiment 3

[0033] 1. Dilute the concentration of polyvinylpyrrolidone-graphene composite aqueous solution made in the laboratory to 0.05mg / ml, and spread the composite on the surface of silicon oxide / silicon base in the form of a single-layer film by spin coating.

[0034] 2. Plating a layer of silver electrode with a thickness of 100nm on the half surface of the monolayer film.

[0035] 3. Imaging in CAFM mode and determining the position of the measured sample.

[0036] 4. Adjust the relative humidity of the surrounding environment to 30%, 40%, 50%, 60%, 70%, 80%, and 90%, apply a bias voltage of 1V to the tested point through the probe, and perform I-V curves under different humidity Measurement.

[0037] During the preparation of the humidity sensor, the optimum concentration of the compound was determined to be 0.02 mg / ml by adjusting the concentration of the polyvinylpyrrolidone-graphene compound; in addition, by selecting different electrodes and their thicknesses, the best elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com