Processor for ultrasonic wave with mixed wavelengths

A hybrid wavelength and ultrasonic technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as single frequency band, circuit board surface damage, etc., to strengthen ultrasonic cleaning, reduce damage, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment specifically describes a mixed-wavelength ultrasonic processor provided by the present invention, the processor includes a cleaning tank and at least one ultrasonic vibration box;

[0048] The ultrasonic vibration box is placed inside the cleaning tank;

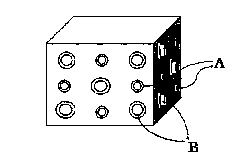

[0049] Such as figure 1 As shown, the ultrasonic vibration box includes at least one mega-frequency short-wave ultrasonic generator and at least one low-frequency long-wave ultrasonic generator.

[0050] The ultrasonic vibration box is placed at the bottom of the cleaning tank or at the side of the interior.

[0051] Regarding the location of the ultrasonic vibration box inside the cleaning tank, this is because ultrasonic waves can also be divided into longitudinal waves and transverse waves, and transverse waves cannot propagate in liquid and gas media because liquid and gas have no shear elasticity. At the same time, due to the high frequency of the ultrasonic wave, the wavelength is very short, an...

Embodiment 2

[0076] This embodiment specifically describes the situation of using the hybrid ultrasonic processor provided by the technical solution of the present invention to conduct an extraction experiment on the traditional Chinese medicine Gorgon fruit, and then perform high performance liquid chromatography detection on the processed sample.

[0077] The specific experimental steps are as follows:

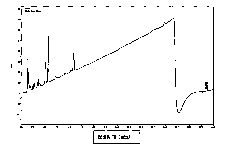

[0078] Take commercially available Gorgon seed kernels, crush them, dry them to constant weight, accurately weigh 5g of Gorgon powder, add 50ml of water into a volumetric flask, and use a low-frequency long-wave ultrasonic generator with a frequency of 23KHz combined with an ultrasonic transducer with a frequency of 1.7MHz for ultrasound. Extraction, after 10 minutes, as a necessary operation before the injection of high performance liquid chromatography, first filter the test solution with a syringe membrane filter with a filter membrane diameter of 0.45 μm as the solution to be tested, ...

experiment example 3

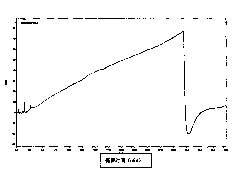

[0084] This embodiment specifically describes the use of the hybrid ultrasonic processor provided by the technical solution of the present invention to conduct an extraction experiment on propolis, and a comparative test of extraction using a single low-frequency ultrasonic processor, and then perform high-efficiency liquid extraction on the two samples after treatment. Phase chromatography detection.

[0085] The specific experimental steps are as follows:

[0086]Take propolis, pulverize, dry to constant weight, accurately weigh 0.5g of propolis powder, add 50ml of methanol into a volumetric flask, use a low-frequency long-wave ultrasonic generator with a frequency of 23KHz combined with an ultrasonic transducer with a frequency of 1.7MHz for ultrasonic extraction, 10min Finally, filter the test solution with a syringe membrane filter (0.45 μm) to be the solution to be tested, take 10 μl and put it into a sample bottle for testing. The detection result is the extraction pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com