Method for preparing calcium silicate nanowires in batches at low cost

A calcium silicate and nanowire technology, applied in the direction of silicate, alkaline earth metal silicate, etc., to achieve the effects of abundant raw material sources, low-cost batch preparation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

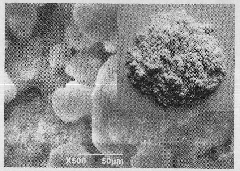

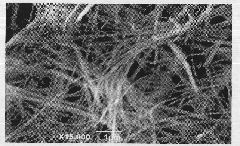

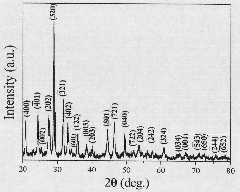

[0029] Embodiment 1: the mixture of calcium oxide and silicon dioxide accounting for 20% of the water solvent quality is mixed with water and then placed in a closed container and sealed, wherein the filling degree of calcium oxide, silicon dioxide mixture and solvent total amount in the container is 50%, stir evenly, keep warm at a temperature of 150°C and a pressure of 1 MPa for 24 hours, and stir with a magnetic stirrer. After the end of the heat preservation, the aqueous solution containing the white loose substance was collected after natural cooling, and the flocculent and loose white powder was collected after drying in an oven at 100°C. Calcined at 800°C for 1 hour in a muffle furnace, and collected flocculent and loose calcium silicate nanowires after natural cooling.

Embodiment 2

[0030] Embodiment 2: the mixture of calcium oxide and silicon dioxide accounting for 20% of the water solvent quality is mixed with water and then placed in a closed container and sealed, wherein the filling degree of calcium oxide, silicon dioxide mixture and solvent total amount in the container is 30%, uniformly stirred, kept at a temperature of 200°C and a pressure of 2 MPa for 36 hours, and stirred with a magnetic stirrer. After the end of the heat preservation, the aqueous solution containing the white loose substance was collected after natural cooling, and the flocculent and loose white powder was collected after drying in an oven at 100°C. Calcined at 800°C for 1 hour in a muffle furnace, and collected flocculent and loose calcium silicate nanowires after natural cooling.

Embodiment 3

[0031] Embodiment 3: the mixture of calcium oxide and silicon dioxide accounting for 10% of the water solvent quality is mixed with water and then placed in an airtight container and sealed, wherein the filling degree of calcium oxide, silicon dioxide mixture and solvent total amount in the container is 30%, uniformly stirred, kept at a temperature of 250° C. and a pressure of 4 MPa for 12 hours, and stirred with a magnetic stirrer. After the end of the heat preservation, the aqueous solution containing the white loose substance was collected after natural cooling, and the flocculent and loose white powder was collected after drying in an oven at 100°C. Calcined at 800°C for 1 hour in a muffle furnace, and collected flocculent and loose calcium silicate nanowires after natural cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com