Method for accelerating fish curing and flavor ripeness

A mature and flavorful technology, applied in the field of accelerated fish pickling and flavor ripening, can solve the problems of increased toughness of tissue structure, denaturation of fish meat protein, and reduced edibility, etc., to achieve improved edibility and gelatinity, improved utilization rate, and quality Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

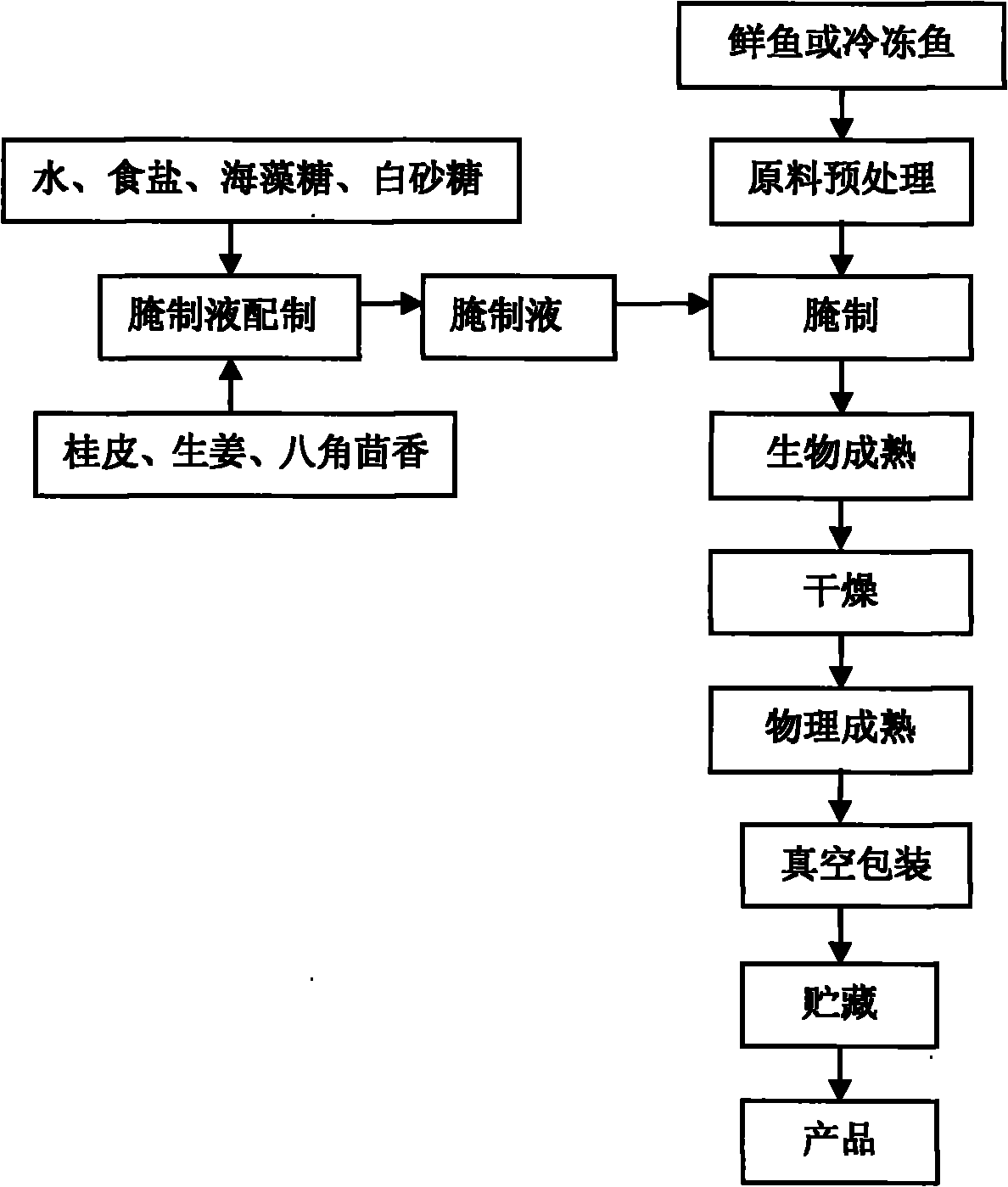

Method used

Image

Examples

Embodiment 1

[0030] Use fresh fish as raw material, remove the head, viscera, scales, rinse with water, cut into fish pieces, put the fish pieces in the pickling solution, the mass ratio of fish pieces: pickling solution is 1:4, and the pickling temperature is 15 Below ℃, then marinated under vacuum conditions for 2 hours, vacuum degree ≥ 0.085MPa, take out after marinating, and drain. Prepare 0.4% flavorzyme flavor enzyme solution according to the mass ratio, then place the pickled fish pieces in the enzyme solution for soaking, the mass ratio of the pickled fish pieces to the enzyme solution is 1:2, and the soaking time is 4 hours; - Combined drying with hot air, first vacuum-dry at 45°C for 3 hours, vacuum degree 0.095MPa, then dry with hot air, and dry at 50°C for 10 hours; the dried fish pieces are treated with intermittent microwave at a microwave temperature of 60 ℃, time 60s, then take out the fish pieces, repeat the above operation after cooling down, a total of 3 times; vacuum pa...

Embodiment 2

[0038]Use fresh fish as raw material, remove the head, viscera, scale, rinse with water, cut into fish pieces, put the fish pieces in the pickling solution, the mass ratio of fish pieces: pickling solution is 1:5, and the pickling temperature is 15 Below ℃, then marinated under vacuum conditions for 3 hours, vacuum degree ≥ 0.085MPa, take out after marinating, and drain. Prepare 0.2% flavorzyme flavor enzyme solution according to the mass ratio, then place the pickled fish pieces in the enzyme solution to soak, the mass ratio of the pickled fish pieces to the enzyme solution is 1: 2.5, and the time is 3 hours; vacuum- Combined hot air drying, temperature 45°C, first vacuum drying for 4 hours, vacuum degree 0.08MPa, then hot air drying, drying at 55°C for 8 hours; the dried fish pieces were treated with intermittent microwave, microwave temperature 90°C, The time is 20s, then take out the fish pieces, repeat the above operation after cooling, and process 3 times in total; vacuu...

Embodiment 3

[0041] Use fresh fish as raw material, remove the head, viscera and scales, rinse with water, cut into fish pieces, put the fish pieces in the pickling solution, the mass ratio of fish pieces: pickling solution is 1:6, and the pickling temperature is 15 Below ℃, then pickled under vacuum conditions for 4 hours, vacuum degree ≥ 0.085MPa, take out after pickling, and drain. Prepare 0.5% flavorzyme flavor enzyme solution according to the mass ratio, and then soak the pickled fish pieces in the enzyme solution, the mass ratio of the pickled fish pieces to the enzyme solution is 1:3, and the time is 2 hours; vacuum- Combined drying with hot air, temperature 45°C, first vacuum drying for 5 hours, vacuum degree 0.06MPa, then drying with hot air, drying at 65°C for 6 hours; the dried fish pieces were treated with intermittent microwave, microwave temperature 75°C, The time is 40s, then take out the fish pieces, repeat the above operation after cooling, and process 3 times in total; va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com