Method for producing bacillus natto comprehensive enzyme low-molecular beverage

A low-molecular-weight, production method technology, applied in application, food preparation, food science and other directions, can solve problems such as fermented beverages with natto bacteria, achieve strong environmental tolerance, inhibit the production of angiotensin, reduce The effect of blood pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

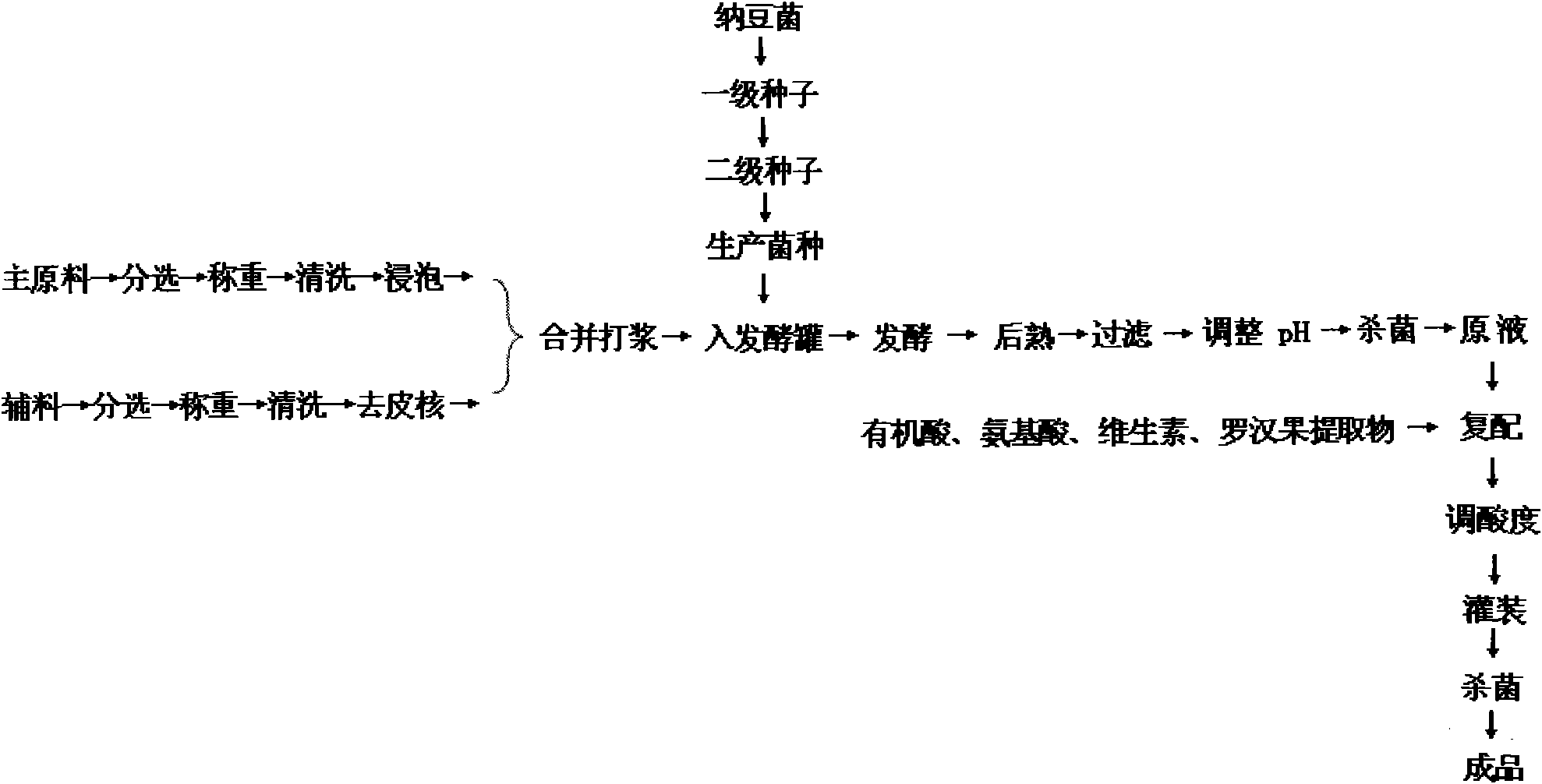

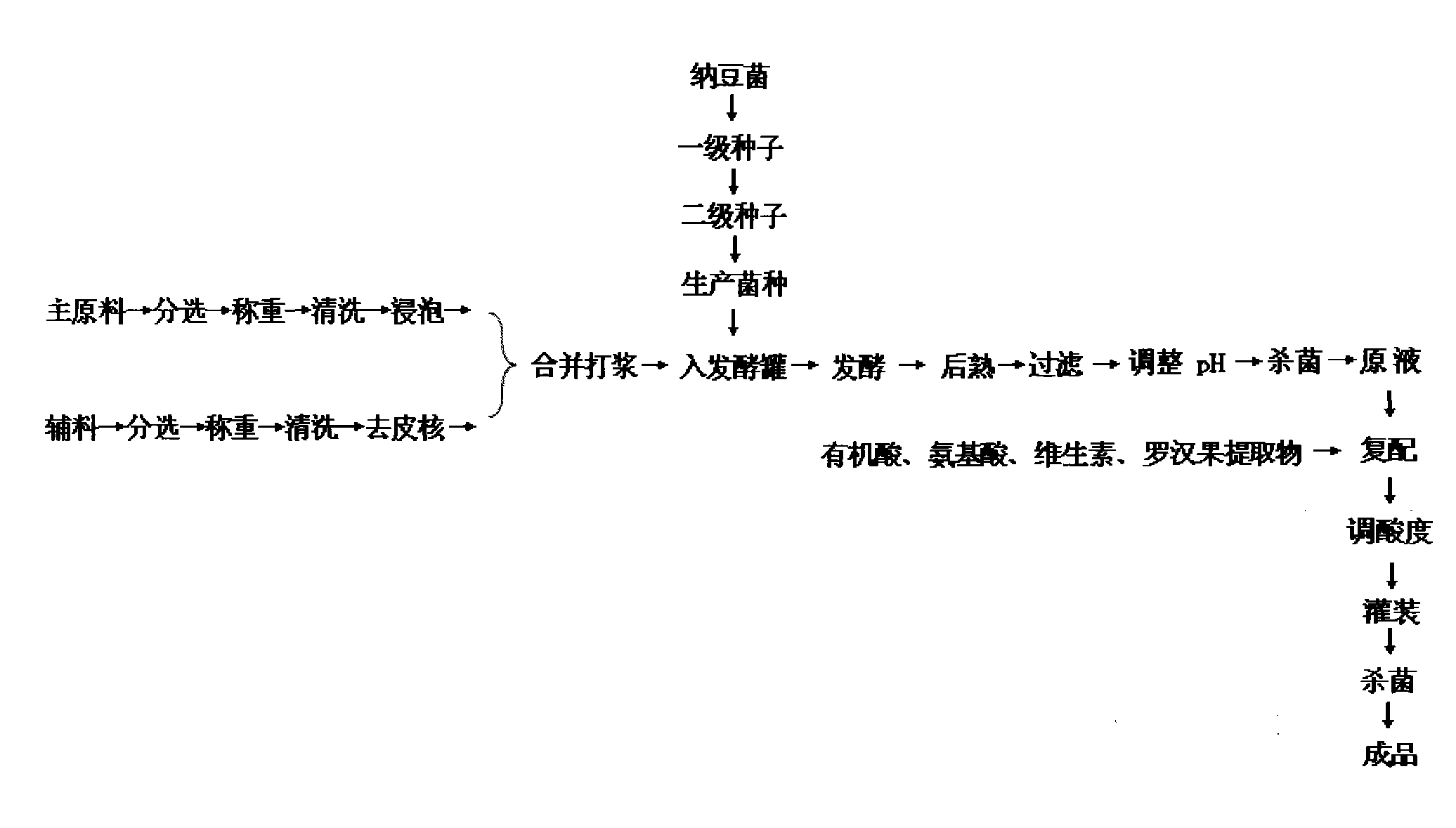

Method used

Image

Examples

Embodiment 1

[0031] Low-molecular beverages are produced with peanuts as the main raw material.

[0032] Weigh 10kg of peanuts, remove sundries and bad kernels, rinse with clean water twice, add 30-50kg of pure water to soak for 8-12 hours. Weigh 2 kg each of pumpkin and carrot, rinse with water twice, peel the pumpkin and cut into small pieces together with the carrot. Peanuts, pumpkins, and carrots are combined and beaten, with a particle size of 80-100 mesh, to make 100kg of plant fermentation liquid, which is put into a fermentation tank and sterilized at 121°C for 20-30 minutes. Insert Bacillus natto seed liquid at 5% and ferment for 2-3 months at 30-37°C. Transfer the fermented liquid to 10°C and ripen for 4-5 months. Filtrate, control the molecular weight below 1000, adjust the pH to 3.5-3.7, sterilize, make a low-molecular-weight enzyme stock solution, and seal it for storage.

[0033] Low-molecular beverage raw liquid, add citric acid, malic acid, amino acids, vitamins, blend i...

Embodiment 2

[0035] Produce low-molecular beverages with soybeans as the main raw material.

[0036] Weigh 20kg of soybeans, remove sundries and bad seeds, rinse with clean water twice, add 80-120kg of pure water to soak for 8-12 hours. Weigh 4 kg each of carrots and apples, rinse them twice with water, peel and core the apples, and cut them into small pieces together with the carrots. Soybeans, apples, and carrots are combined and beaten, with a particle size of 80-100 mesh, to make 200kg of plant fermentation liquid, which is put into a fermenter and sterilized at 121°C for 20-30 minutes. Insert Bacillus natto seed liquid at 3%, and ferment for 2-3 months at 30-37°C. Transfer the fermented liquid to 10°C and ripen for 4-5 months. Filtrate, control the molecular weight below 1000, adjust the pH to 3.5-3.7, sterilize, make a low-molecular-weight enzyme stock solution, and seal it for storage.

[0037] Low-molecular beverage raw liquid, add citric acid, malic acid, amino acids, vitamins,...

Embodiment 3

[0039] Low-molecular beverages are produced with corn as the main raw material.

[0040] Weigh 10kg of corn and 5kg of soybean, remove sundries and bad seeds, rinse with clean water twice, add 80-100kg of pure water to soak for 8-12 hours. Weigh 3 kg of carrots, rinse them twice with water, and cut them into small pieces. Corn, soybean, and carrot are combined and beaten, the particle size is 80-100 mesh, and 150kg of plant fermentation liquid is made, which is input into the fermenter and sterilized at 121°C for 20-30 minutes. Insert Bacillus natto seed liquid at 2%, and ferment for 2-3 months at 30-37°C. Transfer the fermented liquid to 10°C and ripen for 4-5 months. Filtrate, control the molecular weight below 1000, adjust the pH to 3.5-3.7, sterilize, make a low-molecular beverage stock solution, and store in a sealed container.

[0041] Low-molecular-weight beverage raw liquid, adding Luo Han Guo extract, citric acid, malic acid, amino acids, vitamins, blended into a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com