Preparation method of PVC (Polyvinyl Chloride) phenol-free heat stabilizer

A heat stabilizer and solvent technology, applied in the field of plastic additives, can solve the problems of not considering environmental protection, poor thermal stability, high price constraints, etc., and achieve the effects of simple process, reduced consumption and energy saving

Inactive Publication Date: 2010-08-25

INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

View PDF1 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In recent years, my country has imported a certain amount of environmentally friendly calcium-zinc stabilizers to meet the needs of the domestic plastics processing industry, but its price is relatively high

On the other hand, the current domestic research and production of calcium and zinc are still in the exploratory stage, and the thermal stability of domestic calcium soap zinc soap compound stabilizers is relatively poor

Just because there are no mature products in China, and the high price of imported products restricts the promotion of lead ban in China, it has formed a situation where domestic PVC products basically do not consider environmental protection, leading to the situation that imported products and some higher-grade PVC products have to use imported heat stabilizers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

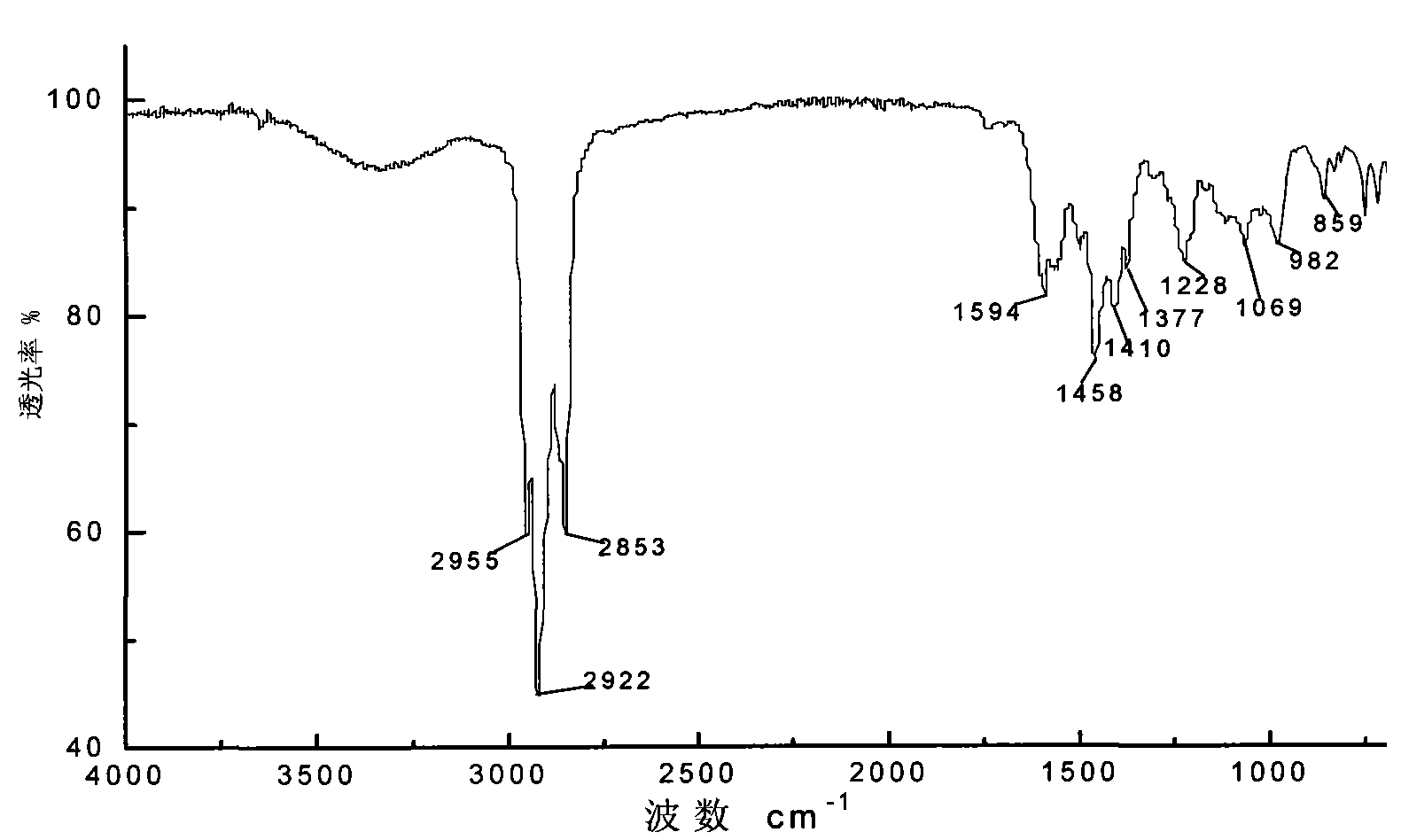

The invention discloses a preparation method of a PVC (Polyvinyl Chloride) phenol-free heat stabilizer. The preparation method comprises the following steps of: (1) putting a certain quantity of eleostearic acid in a reaction bulb and stirring and heating to 65-75 DEG C; adding maleic anhydride according to a molar ratio of 1:(0.5-1.5) and then raising the temperature to 100-180 DEG C; refluxing for 1-6h, distilling under a vacuum degree of 2mmHg to remove nonreactive substances and decolorizing by using active carbon to obtain elaeostearic anhydride which is an intermediate product; (2) taking any two metallic compounds of zinc oxide, calcium hydroxide and magnesium oxide and uniformly stirring the metallic compounds respectively with the elaeostearic anhydride and a solvent; then adding a defoaming agent and a phenol-free antioxidant to react to obtain eleostearates corresponding to two metals; (3) uniformly mixing a proper quantity of the eleostearates of the two metals and then reacting with the solvent and the phenol-free antioxidant; and filtering to obtain the PVC phenol-free composite heat stabilizer. The prepared phenol-free heat stabilizer is applied to the field of the processing of PVC plastics. The prepared phenol-free heat stabilizer can improve the initial dyeing property and the long-term heat stability of the PVC and has low price.

Description

technical field The invention belongs to the field of plastic additives, in particular to a method for preparing a PVC phenol-free heat stabilizer. Background technique Polyvinyl chloride (PVC) is the second largest synthetic resin after polyethylene, and is widely used in construction, telecommunications, transportation, electronics, chemicals, packaging and other industries. Due to the poor thermal stability of PVC, the difference between softening temperature and decomposition temperature is very small, which brings great difficulties to processing. Therefore, a certain amount of heat stabilizer must be added during its processing to improve its thermal stability. At present, heat stabilizers on the market mainly include lead salts, metal soaps, organotins, and rare earths. For a long time, lead salt and barium cadmium soap stabilizers have dominated the world and China PVC heat stabilizer market due to their low price and excellent performance. Very strict restriction...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/06C08K5/00C08K5/098

Inventor 夏建陵聂小安蒋剑春徐俊明李梅

Owner INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com