Ferrite stainless steel and manufacturing method thereof

A manufacturing method and stainless steel technology, applied in the field of ferritic stainless steel and its manufacturing, can solve problems such as reducing formability and increasing cost, and achieve the effects of overcoming corrosion resistance and formability, extending annealing time, and improving corrosion resistance.

Active Publication Date: 2010-08-25

BAOSTEEL DESHENG STAINLESS STEEL

View PDF2 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This invention reduces the generation of steel precipitates by controlling the element content to meet a certain formula, and improves the performance of the steel by controlling the grain size, but it should be pointed out that in actual production, the precise element content must meet a certain formula It is not an easy task, and the invention contains precious metals such as Cu and Ni in addition, which undoubtedly increases the cost of the invention

There is a certain conflict between the corrosion resistance and formability of traditional ferritic stainless steel for household appliances. Improving corrosion resistance often reduces its formability. Such a ferritic stainless steel with the contradiction between corrosion resistance and formability of stainless steel is widely used in household appliances and other industries

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

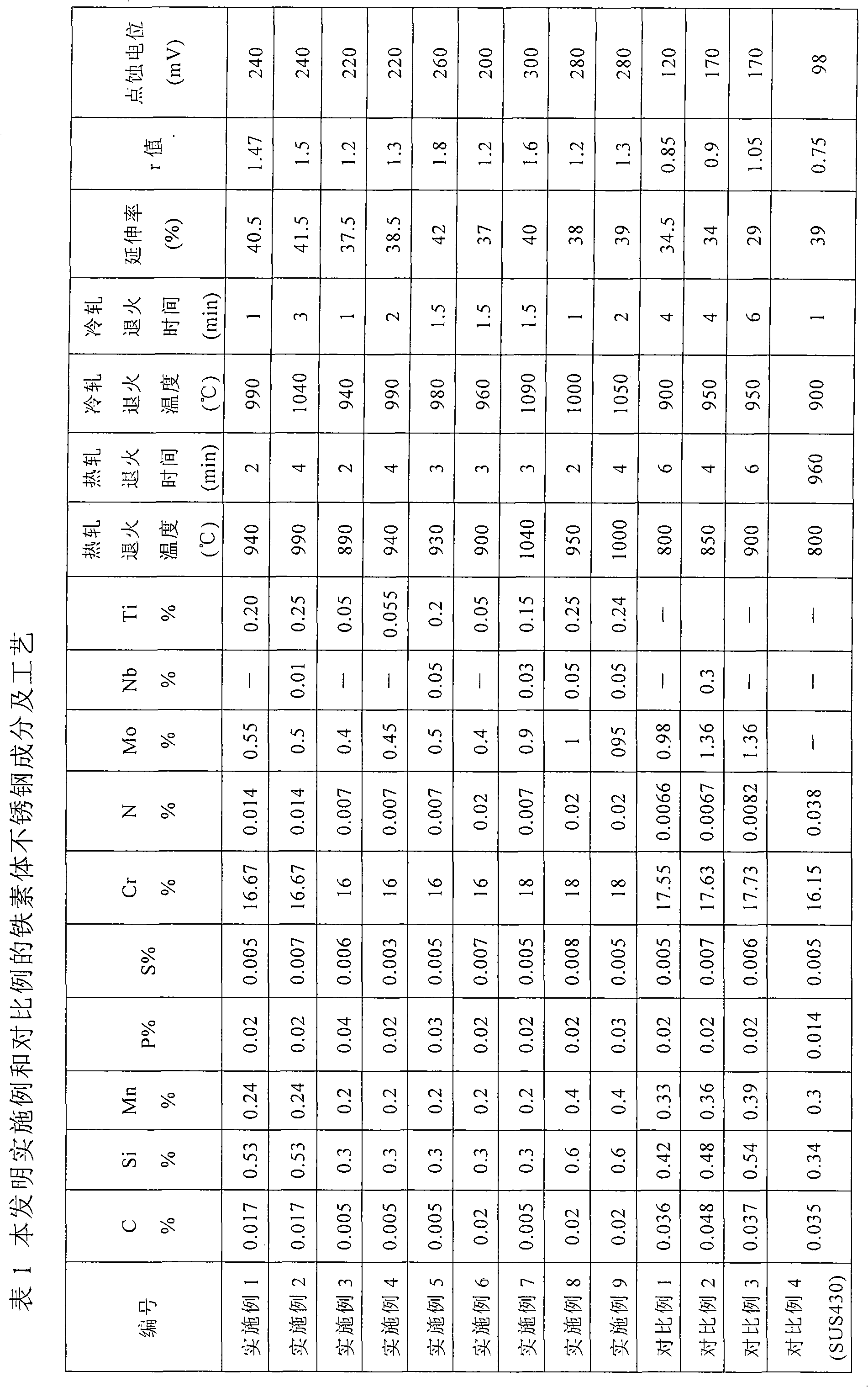

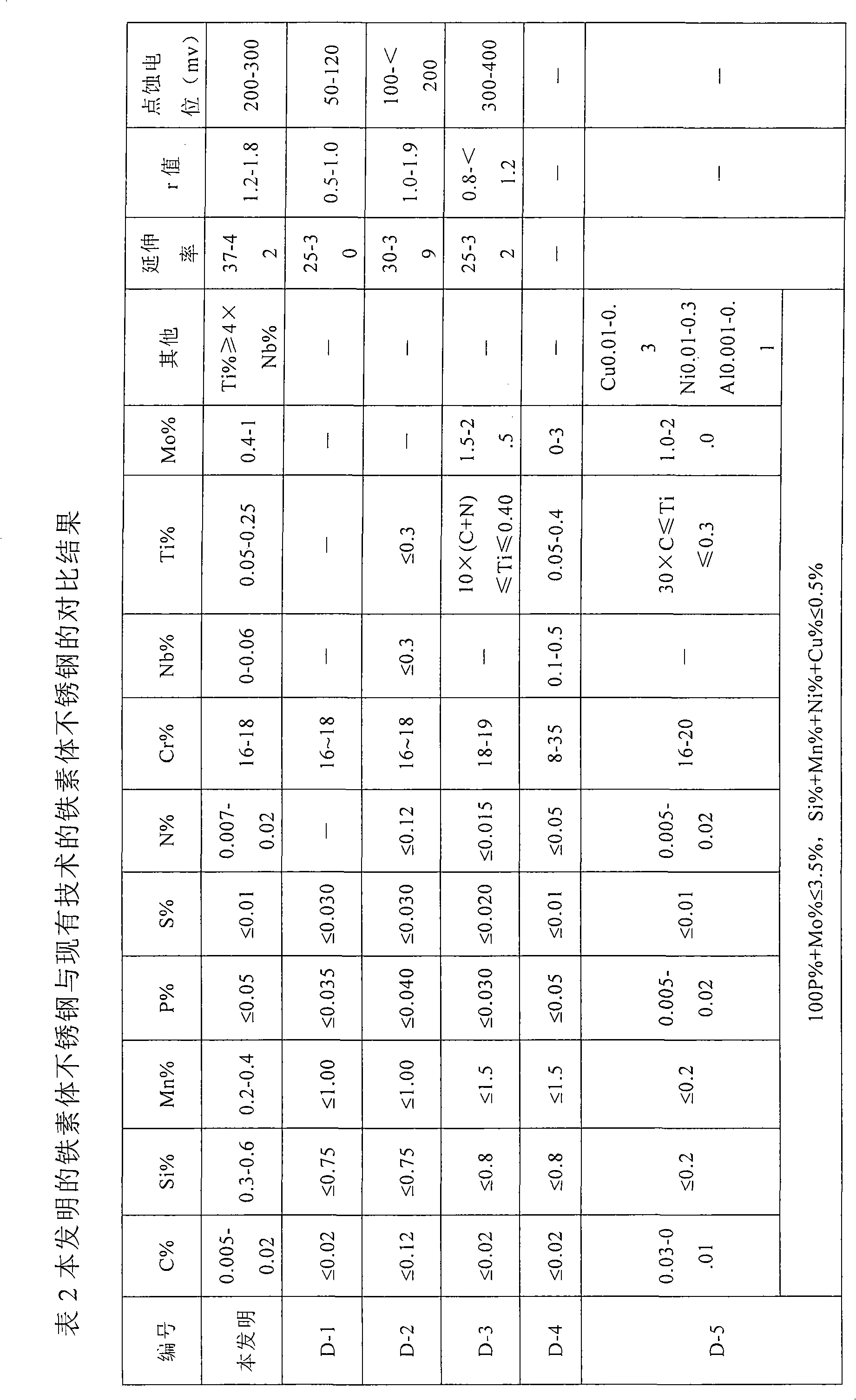

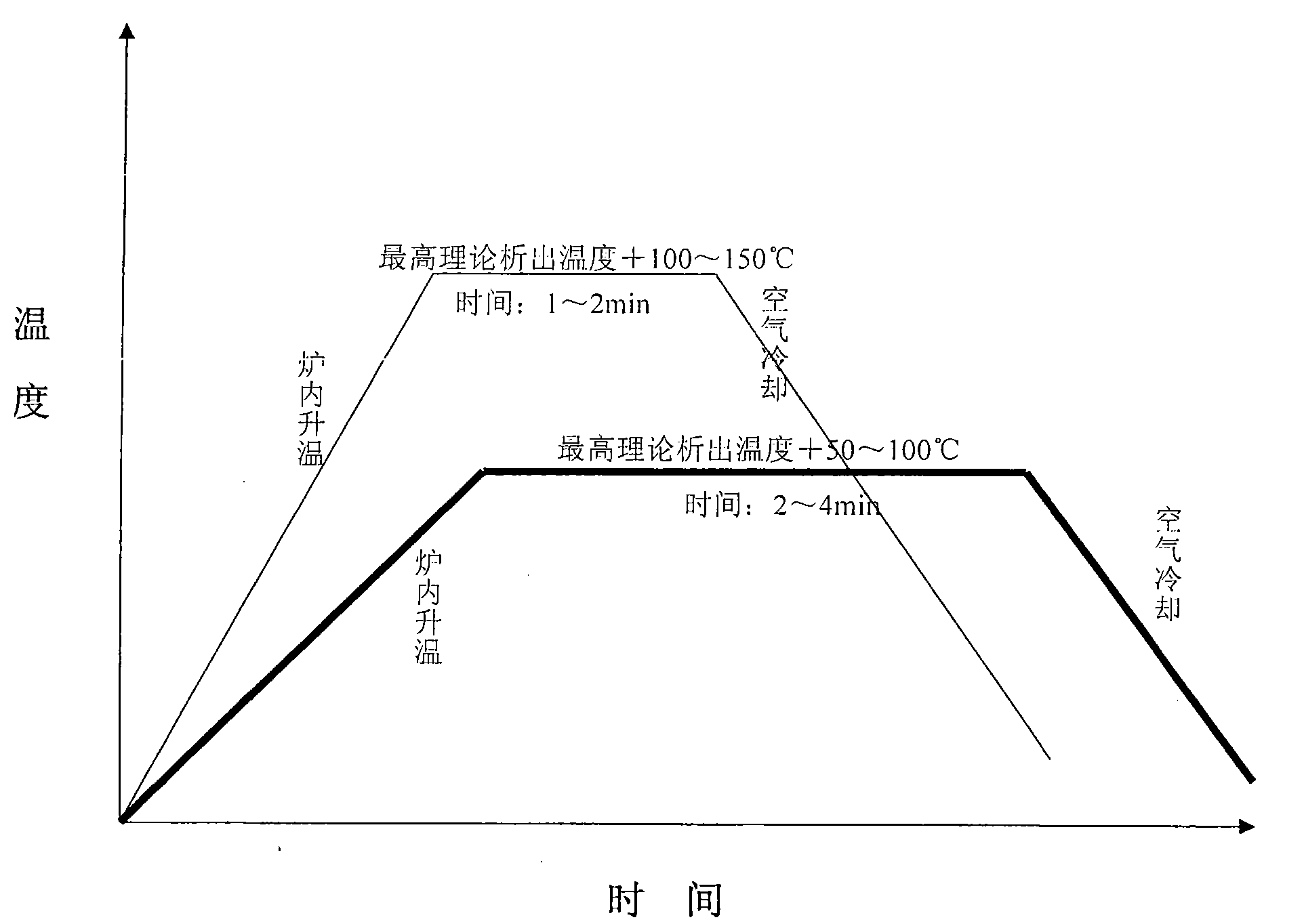

Ferrite stainless steel comprises the following components in percentage by weight: less than or equal to 0.02 percent of C, 0.30 to 0.60 percent of Si, 0.20 to 0.40 percent of Mn, less than or equal to 0.01 percent of S, less than or equal to 0.05 percent of P, 1.60 to 18.0 percent of Cr, less than or equal to 0.02 percent of N, 0.4 to 1 percent of Mo, 0 to 0.06 percent of Nb, 0.05 to 0.25 percent of Ti and the balance of Fe and inevitable impurities, wherein Ti is more than or equal to 4*Nb. The method for manufacturing the ferrite stainless steel comprises the following steps: smelting by an electric furnace-AOD-VOD three-step method; performing casting, hot rolling, annealing and acid washing, cold rolling and annealing and acid washing processes; calculating theological precipitationtemperatures of M23C6, sigma phase and chi phase according to a Thermo-calc phase diagram and taking a maximum value x DEG C of the precipitation temperatures of three precipitated phases, wherein the hot rolling and annealing temperature is equal to the highest theological temperature x DEG C plus 50 to 100 DEG C, and the annealing time is between 2 and 4 minutes; and the cold rolling and annealing temperature is equal to the highest theological temperature x DEG C plus 100 to 150 DEG C, and the annealing time is between 1 and 3 minutes; and performing air cooling after annealing. Prepared Mo-containing ferrite stainless steel has excellent corrosion resistance and moldability, and can be widely applied in household appliance industry.

Description

A kind of ferritic stainless steel and its manufacturing method technical field The present invention relates to ferritic stainless steel and its manufacturing method, in particular to Mo-containing ferritic stainless steel and its manufacturing method. Background technique Ferritic stainless steel is widely used in industries such as household appliances. From a wide variety of household appliances such as the inner shell of the microwave oven, the inner barrel of the washing machine, the rice cooker, the inner tank of the electric water heater, and the electric thermos, to the kitchen and bathroom equipment, tableware, and hardware products such as the dishwasher, oven, stove, and disinfection cupboard. my country is a big producer of home appliances, but currently 304 austenitic stainless steel and 430 ferritic stainless steel are mainly used, while foreign countries such as the United States and Japan mainly use ferritic steel. Therefore, ferritic stainless steel has ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/28C22C33/04C21D8/02

Inventor 张鑫孙全社杜伟

Owner BAOSTEEL DESHENG STAINLESS STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com