Method for preparing epitaxial growing nano pattern substrate of nitride

A nano-patterning and epitaxial growth technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of limited brightness improvement, complex process, expensive equipment, etc., to relax stress, reduce dislocation density, and improve performance. Effect

Inactive Publication Date: 2010-08-25

EPILIGHT TECH

View PDF6 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

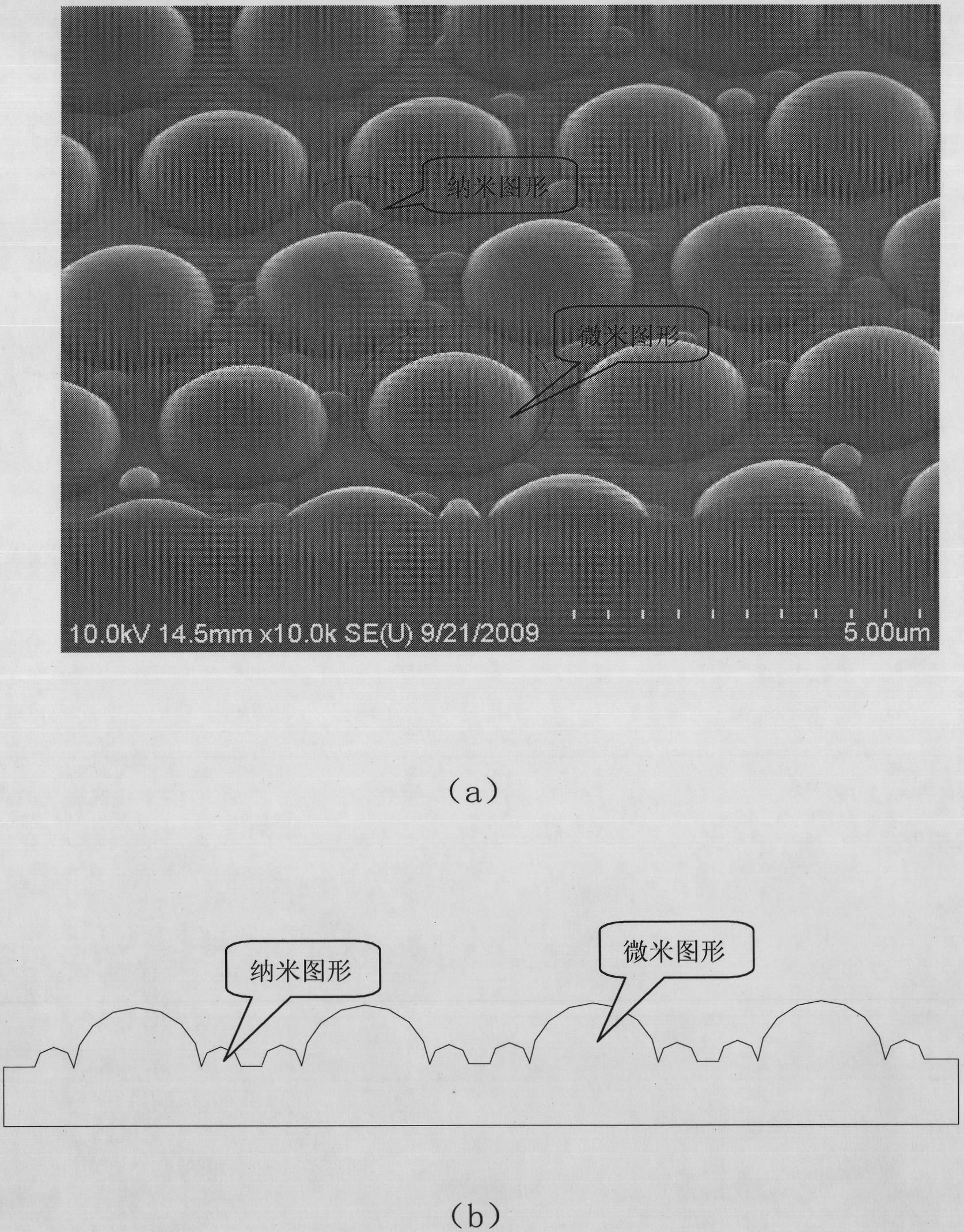

However, at present, this kind of pattern is on the micron scale, which has limited improvement in brightness; compared with the usual micron-scale patterned substrate, the nano-patterned substrate technology can more effectively relax the stress of the growth process of the heterojunction interface, Further reduce the dislocation density of the nitride epitaxial layer, improve the crystal quality of the material and the corresponding device performance

The realization of semiconductor nanoscale patterns usually adopts electron beam lithography or X-ray lithography, but these lithography techniques involve expensive equipment, complicated process and high cost.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

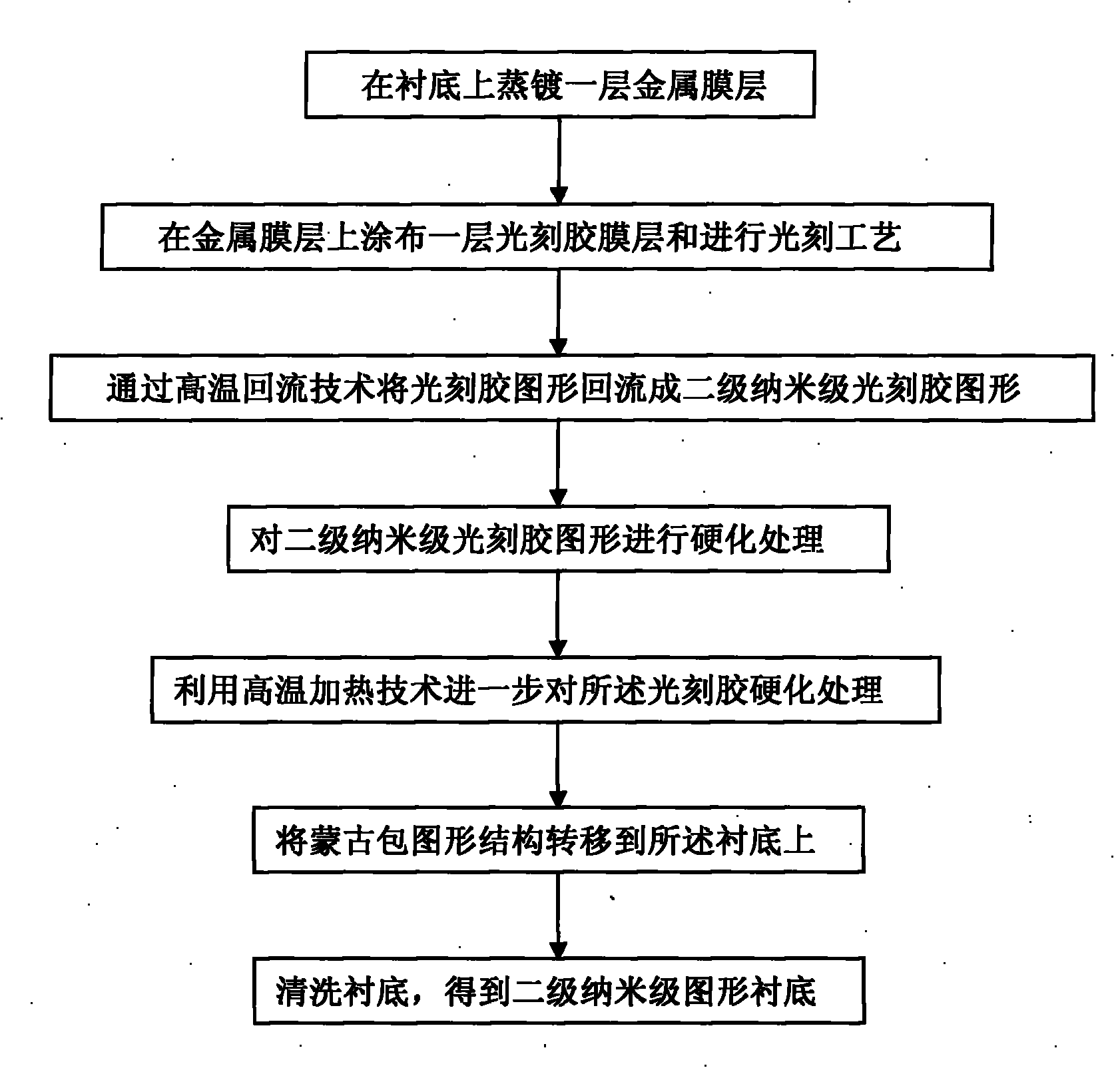

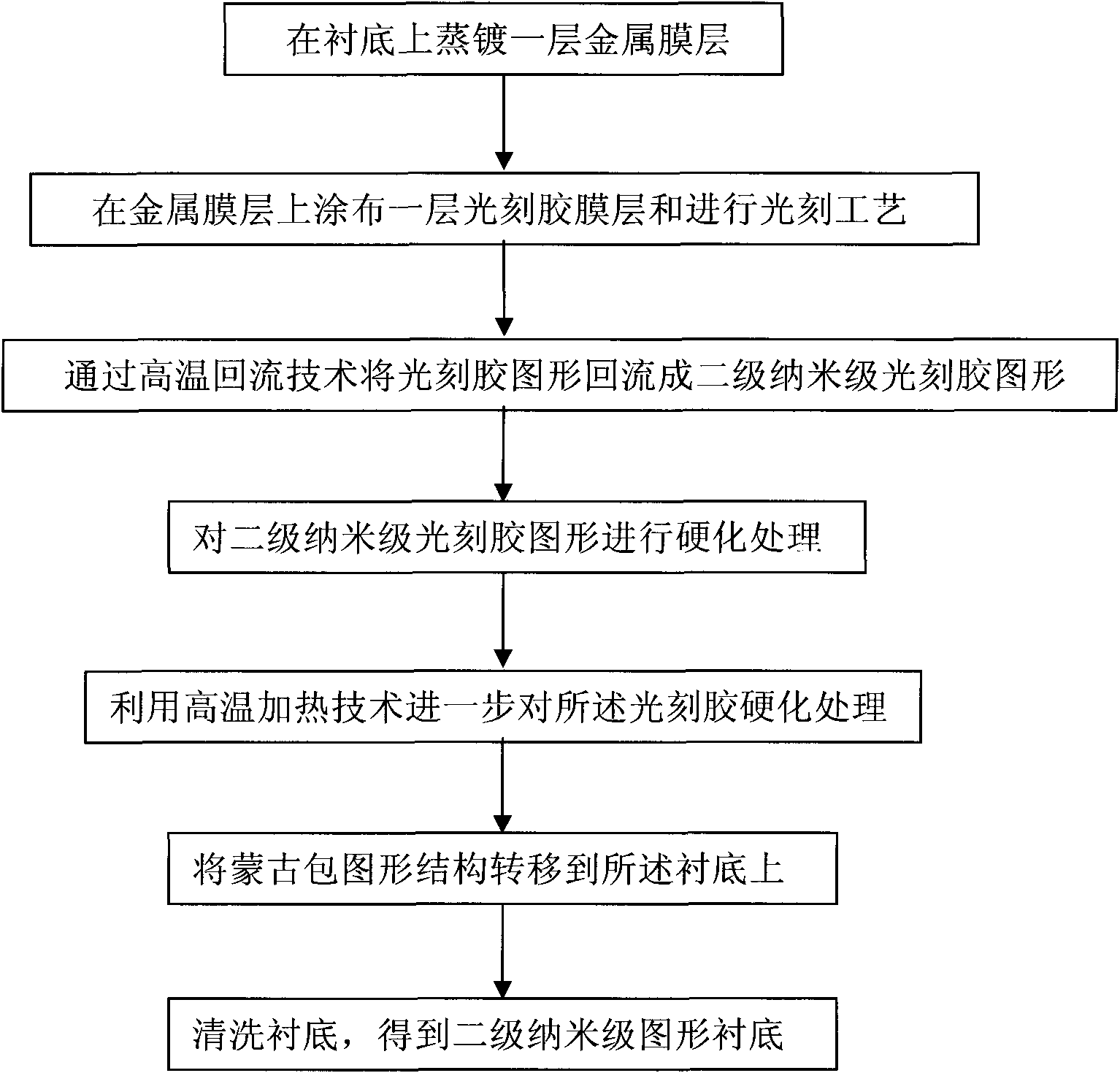

The invention discloses a method for preparing an epitaxial growing nano pattern substrate of a nitride, which comprises the following steps of: evaporating a metal film layer on a substrate; coating a photoresist film layer on the metal film layer; developing nano-size photoresist patterns on the substrate by a photomask technology and retaining a layer of thin photoresist between the patterns; forming two stages of nano-grade photoresist patterns by a high-temperature reflux technology, wherein one stage of nano-grade photoresist pattern is a micron-size pattern, and the other stage of nano-grade photoresist pattern is a nano-size pattern; carrying out hardening processing on the two stages of nano-grade photoresist patterns; further hardening the photoresist patterns by utilizing a photoresist heating and baking technology; transferring the photoresist pattern structures on the substrate by utilizing the two formed stages of nano-grade photoresist patterns as mask films through a dry etching technology; and cleaning the substrate to obtain two stages of nano-grade pattern substrates. The invention can improve the crystal quality of materials and the corresponding device performance.

Description

Preparation method of nano-pattern substrate for nitride epitaxial growth technical field The invention relates to the field of semiconductor light-emitting diodes, in particular to a method for preparing a nitride epitaxy-grown nano-pattern substrate. Background technique Light-emitting diodes have the advantages of small size, high efficiency and long life, and are widely used in traffic indication, outdoor full-color display and other fields. In particular, the use of high-power light-emitting diodes may realize semiconductor solid-state lighting, which has caused a revolution in the history of human lighting, and has gradually become a research hotspot in the field of electronics. In order to obtain high-brightness LEDs, the key is to improve the internal quantum efficiency and external quantum efficiency of the device. At present, the light extraction efficiency of the chip is the main factor limiting the external quantum efficiency of the device. The main reason is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L33/12

Inventor 袁根如郝茂盛陈诚

Owner EPILIGHT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com