Comprehensive treatment process for coking wastewater

A technology for coking wastewater and comprehensive treatment, applied in the field of water treatment, can solve the problems that the produced water cannot be directly used as production water, and the wastewater cannot be completely treated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

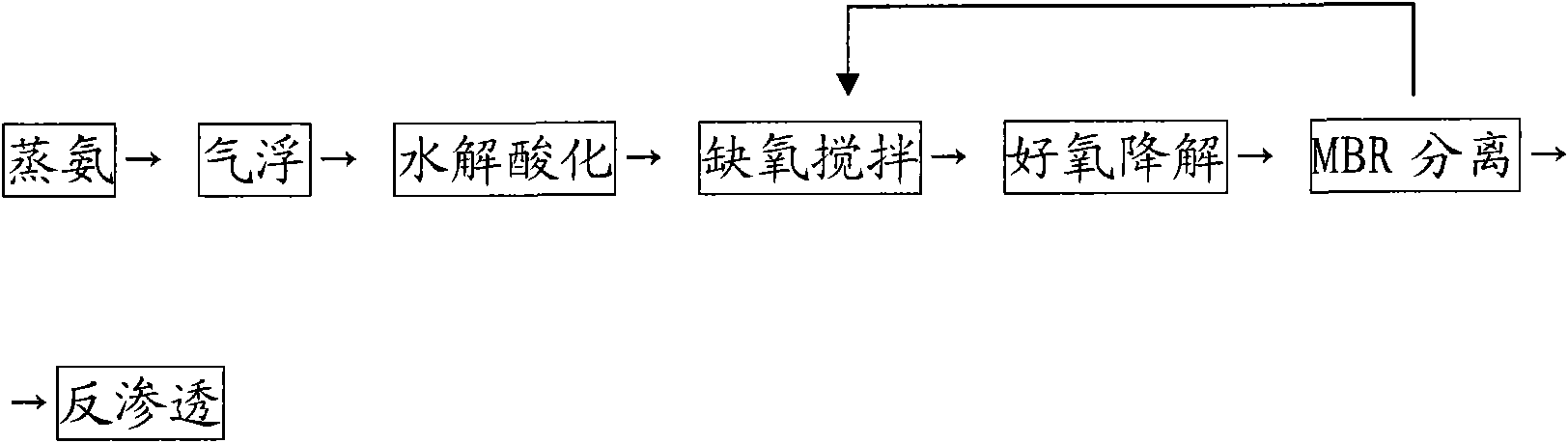

[0039] Such as figure 1 As shown, the flow chart of Embodiment 1 of the present invention.

[0040] A comprehensive treatment process for coking wastewater, comprising the following steps in sequence:

[0041] ① Ammonia distillation step: recovering ammonia from the coking wastewater, so that the ammonia nitrogen of the coking wastewater is less than 200ppm;

[0042] ②Air flotation step: Select the M50-UP15S integrated dissolved air flotation equipment to recover the wastewater obtained from the ammonia distillation step. The treated water volume is 100T / H, the dissolved air-water ratio is 0.06, and 50ppm flocculant and 5ppm coagulant are added. Run the air flotation process, the hydraulic retention time is 30min, and obtain the first-level pretreatment wastewater; the influent water quality COD is 4100ppm, the oil is 38ppm, the effluent water quality COD is 3700ppm, and the oil is <5ppm;

[0043] ③Hydrolytic acidification step: the primary pretreatment wastewater is dischar...

Embodiment 2

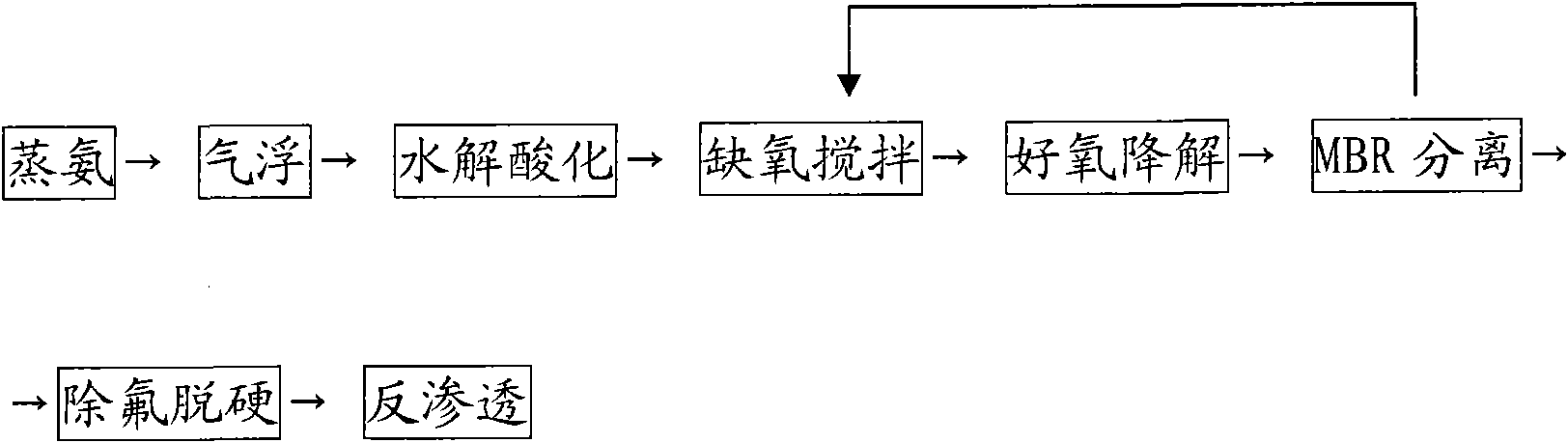

[0052] Such as figure 2 As shown, the flow chart of Embodiment 2 of the present invention.

[0053] A comprehensive treatment process for coking wastewater, comprising the following steps in sequence:

[0054] ① Ammonia distillation step: recovering ammonia from the coking wastewater, so that the ammonia nitrogen of the coking wastewater is less than 200ppm;

[0055] ②Air flotation step: Select the M50-UP15S integrated dissolved air flotation equipment to recover the wastewater obtained from the ammonia distillation step. The treated water volume is 100T / H, the dissolved air-water ratio is 0.06, and 50ppm flocculant and 5ppm coagulant are added. Run the air flotation process, the hydraulic retention time is 30min, and obtain the first-level pretreatment wastewater; the influent water quality COD is 4100ppm, the oil is 38ppm, the effluent water quality COD is 3700ppm, and the oil is <5ppm;

[0056] ③Hydrolytic acidification step: the primary pretreatment wastewater is discha...

Embodiment 3

[0065] A comprehensive treatment process for coking wastewater, comprising the following steps in sequence:

[0066] ① Ammonia distillation step: recovering ammonia from the coking wastewater, so that the ammonia nitrogen of the coking wastewater is less than 200ppm;

[0067] ②Air flotation step: Select the M50-UP15S integrated dissolved air flotation equipment to recover the wastewater obtained from the ammonia distillation step. The treated water volume is 100T / H, the dissolved air-water ratio is 0.06, and 50ppm flocculant and 5ppm coagulant are added. Run the air flotation process, the hydraulic retention time is 30min, and obtain the first-level pretreatment wastewater; the influent water quality COD is 4100ppm, the oil is 38ppm, the effluent water quality COD is 3700ppm, and the oil is <5ppm;

[0068] ③Hydrolytic acidification step: the primary pretreatment wastewater is discharged into the folded plate packing type anaerobic sludge tank; the folded plate packing type ana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com