Method for coating h-BN coating on surface of porous Si3N4 substrate

A substrate and coating technology, applied in the field of coating h-BN coating on the surface of porous Si3N4 substrate, can solve the problems of complex process and high price, and achieve the effect of good quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

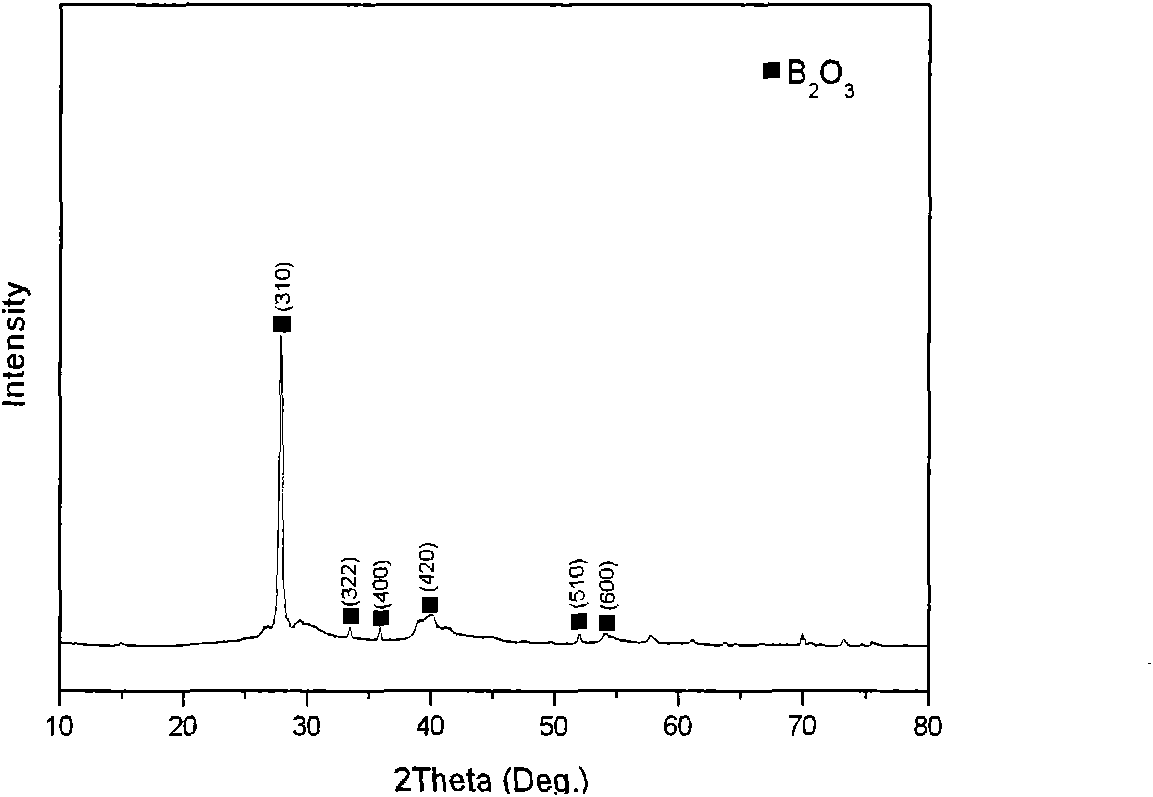

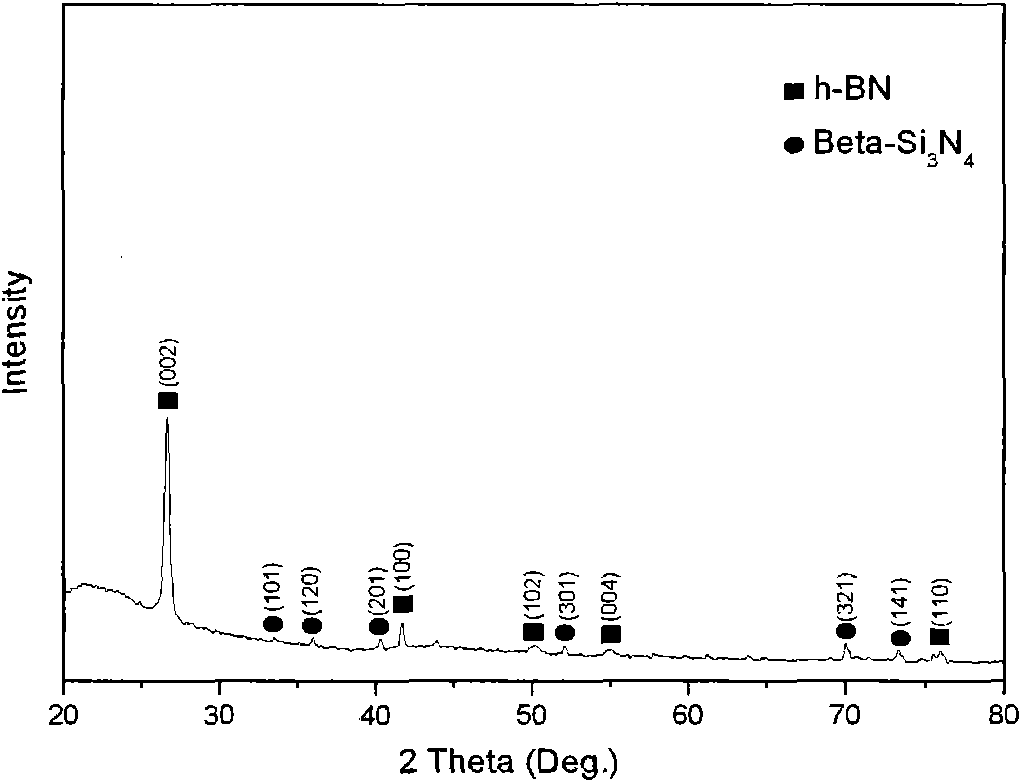

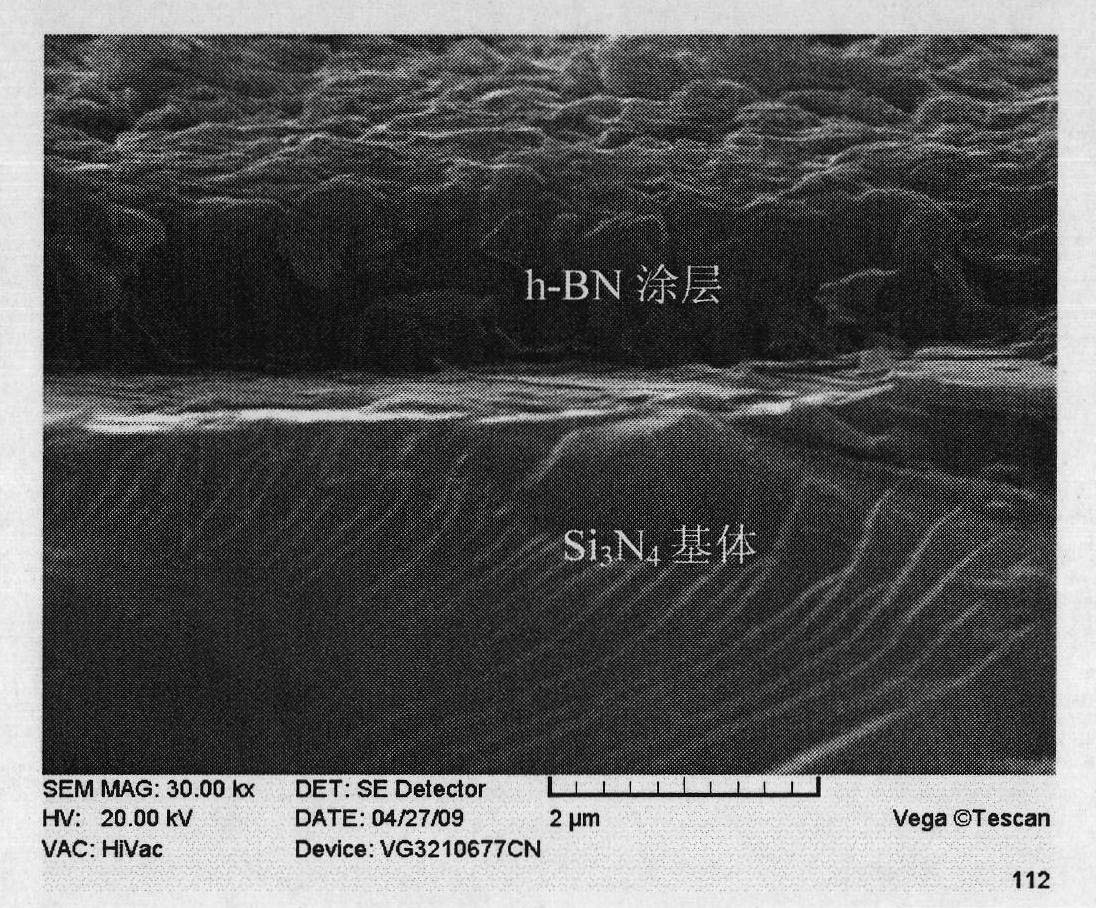

Image

Examples

Embodiment 1

[0018] This embodiment includes the following steps:

[0019] 1. By mass ratio, 30% Si 3 N 4 , 5% of Y 2 o 3 , 5% Al 2 o 3 Mix it with 60% petroleum coke and put it into a ball milling tank, use absolute ethanol as the ball milling medium, and ball mill it with silicon nitride balls for 24 hours to obtain a slurry;

[0020] 2. Dry the prepared slurry in a 40°C drying oven for 12 hours, pass through a 200-mesh sieve to obtain a powder, press the obtained powder into a green disc, and 2 Sintered at 1600°C for 2h in the atmosphere, N 2 The pressure is 3 atmospheres to obtain Si with a porosity of 35% 3 N 4 matrix;

[0021] 3. The sintered Si 3 N 4 The surface of the substrate was cleaned with absolute ethanol, and then dried in a drying oven at 40°C for later use, and then commercial H 3 BO 3 Uniform overcoating on Si 3 N 4 Substrate surface, required H 3 BO 3 Quality and Si 3 N 4 The surface area ratio of the matrix is 0.2g / cm 2 ;

[0022] Four, will be co...

Embodiment 2

[0025] This embodiment includes the following steps:

[0026] 1. Mix 50% Si by mass ratio 3 N 4 , 4% Y 2 o 3 , 6% Al 2 o 3 Mix it with 40% petroleum coke and put it into a ball milling tank, use absolute ethanol as the ball milling medium, and use silicon nitride balls to mill for 48 hours to obtain a slurry;

[0027] 2. Dry the prepared slurry in a drying oven at 60°C for 6 hours, pass through a 200-mesh sieve to obtain a powder, press the obtained powder into a green disc, and 2 Sintered at 1800°C for 2.8h in the atmosphere, N 2 The pressure is 2 atmospheres to obtain Si with a porosity of 25% 3 N 4 matrix;

[0028] 3. The sintered Si 3 N 4 The surface of the substrate was cleaned with absolute ethanol, and then dried in a drying oven at 60°C for later use, and then commercial H 3 BO 3 Uniform overcoating on Si 3 N 4 Substrate surface, required H 3 BO 3 Quality and Si 3 N 4 The surface area ratio of the matrix is 0.3g / cm 2 ;

[0029] Four, will be coat...

Embodiment 3

[0032] This embodiment includes the following steps:

[0033] One, 41% Si by mass ratio 3 N 4 , 5% of Y 2 o 3 , 4%Al 2 o 3 Mix it with 50% petroleum coke and put it into a ball milling tank, use absolute ethanol as the ball milling medium, and ball mill it with silicon nitride balls for 24 hours to obtain a slurry;

[0034] 2. Dry the prepared slurry in a drying oven at 50°C for 9 hours, pass through a 200-mesh sieve to obtain a powder, and press the obtained powder into a green disc. 2 Sintered at 1650°C for 3h in the atmosphere, N 2 The pressure is 2 atmospheres to obtain Si with a porosity of 28% 3 N 4 matrix;

[0035] 3. The sintered Si 3 N 4 The surface of the substrate was cleaned with absolute ethanol, and then dried in a drying oven at 50°C for later use, and then commercial H 3 BO 3 Uniform overcoating on Si 3 N 4 Substrate surface, required H 3 BO 3 Quality and Si 3 N 4 The surface area ratio of the matrix is 0.6g / cm 2 ;

[0036] Four, will be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com