Reactive type sustained-release fertilizer compounded by nitrification inhibitor/urea formaldehyde and preparation method thereof

A technology of nitrification inhibitors and slow-release fertilizers, applied in fertilizer mixtures, applications, fertilization devices, etc., can solve problems such as ecological environmental pollution, nitrate excess, environmental pollution, etc., to reduce release, improve production capacity, and speed up sticking The effect of knot properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

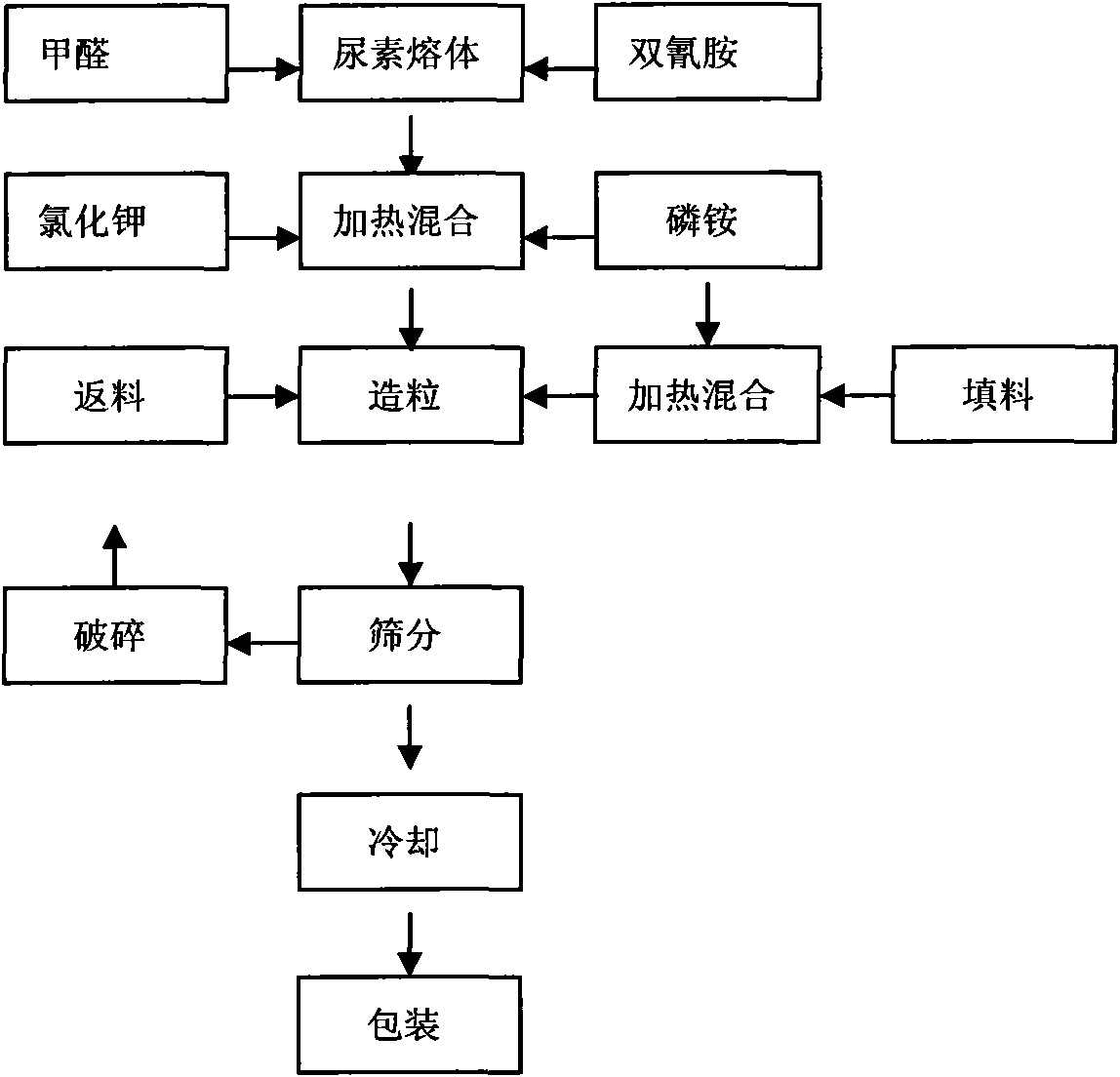

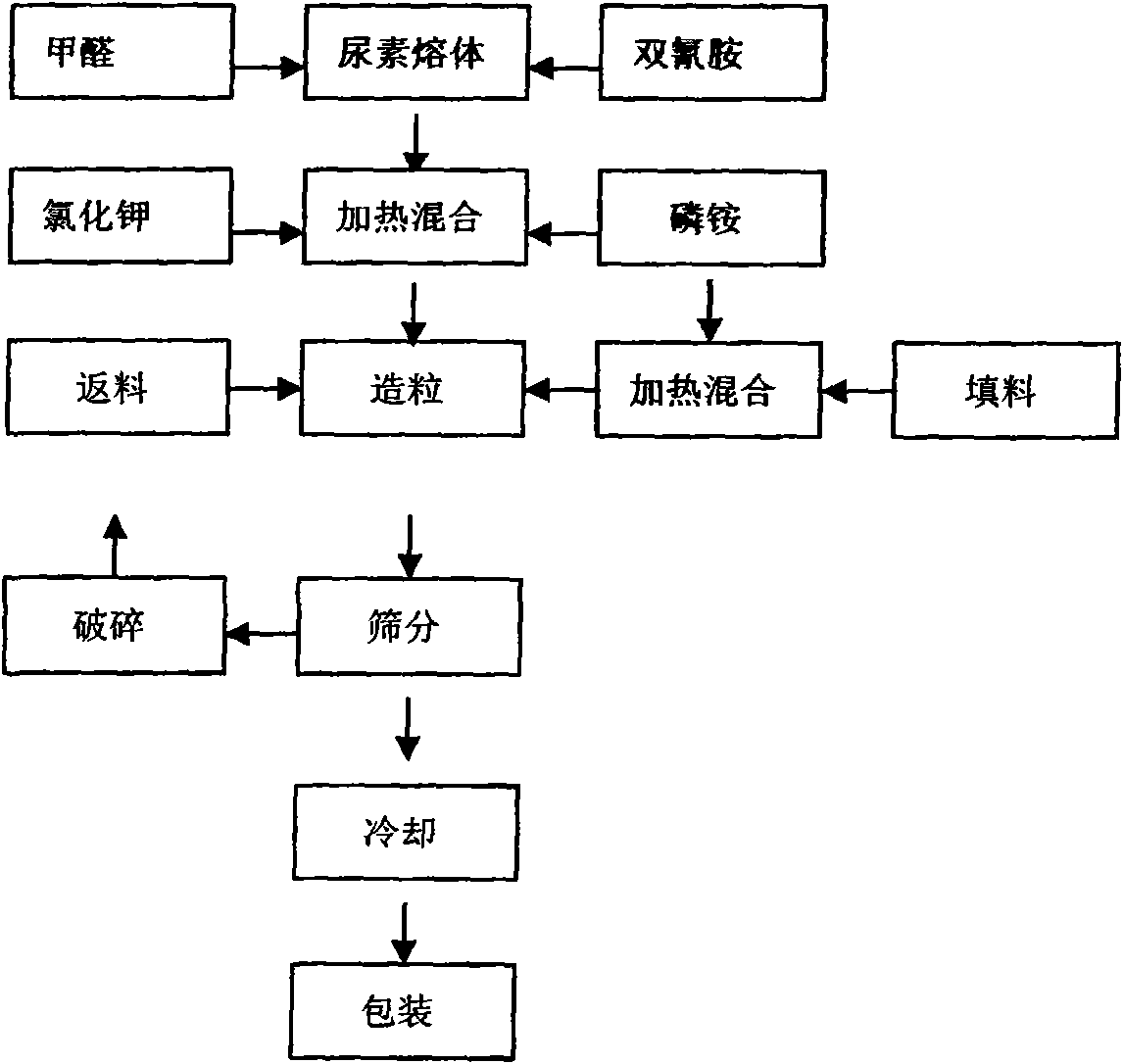

Method used

Image

Examples

Embodiment 1

[0033]In the 50% aqueous solution containing 60 grams of urea, add 162 grams of 37% formaldehyde solution and 84 grams of dicyandiamide, at this moment urea: formaldehyde: the mol ratio of dicyandiamide is 1: 2: 1, heat and mix at 55 ℃ To react, add 0.61 g of 98% sulfuric acid at the same time, control the pH value to 3-4, and perform polycondensation reaction for 2 hours to form a mixed slurry containing slow-release nitrogen. The above-mentioned mixed slurry is transported into the drum granulator, and the pulverized powdered potassium chloride, ammonium phosphate and filler are added, and it can be directly granulated to become a qualified nitrogen, phosphorus and potassium slow-release compound fertilizer.

Embodiment 2

[0035] In the 96% aqueous solution containing 600 grams of urea, add 162 grams of 37% formaldehyde solution and 84 grams of dicyandiamide, at this moment urea: formaldehyde: the mol ratio of dicyandiamide is 10: 2: 1, heat and mix at 95 ℃ , add 10.2 grams of 85% sulfuric acid at the same time, control the pH value of 3 to 4, and form a mixed slurry containing slow-release nitrogen in the polycondensation reaction for 0.5 hours, transport the above mixed slurry into a disc granulator, add Powdered potassium chloride, ammonium phosphate, and fillers can be directly granulated into qualified nitrogen, phosphorus, and potassium slow-release compound fertilizers.

Embodiment 3

[0037] In the 50% aqueous solution containing 60 grams of urea, add 162 grams of 37% formaldehyde solution and 168 grams of calcium cyanamide, at this moment urea: formaldehyde: the mol ratio of calcium cyanamide is 1: 2: 2, at 90 ℃ Heat and mix, add 1.4 grams of 90% phosphoric acid at the same time, control the pH value of 3 to 4, polycondensate for 3 hours to form a mixed slurry containing slow-release nitrogen, transport the above mixed slurry into a drum granulator, add after The crushed powdered potassium sulfate, ammonium phosphate, and fillers can be directly granulated into qualified nitrogen, phosphorus, and potassium slow-release compound fertilizers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com