Method for directly producing water soluble aniline black

A water-soluble nigrosine, direct technology, applied in the direction of benzene azine dyes, organic chemistry, etc., can solve the problems of high energy consumption, long production process cycle, large waste of heat energy, etc., to reduce waste water discharge and improve labor production efficiency , the effect of saving energy and labor resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

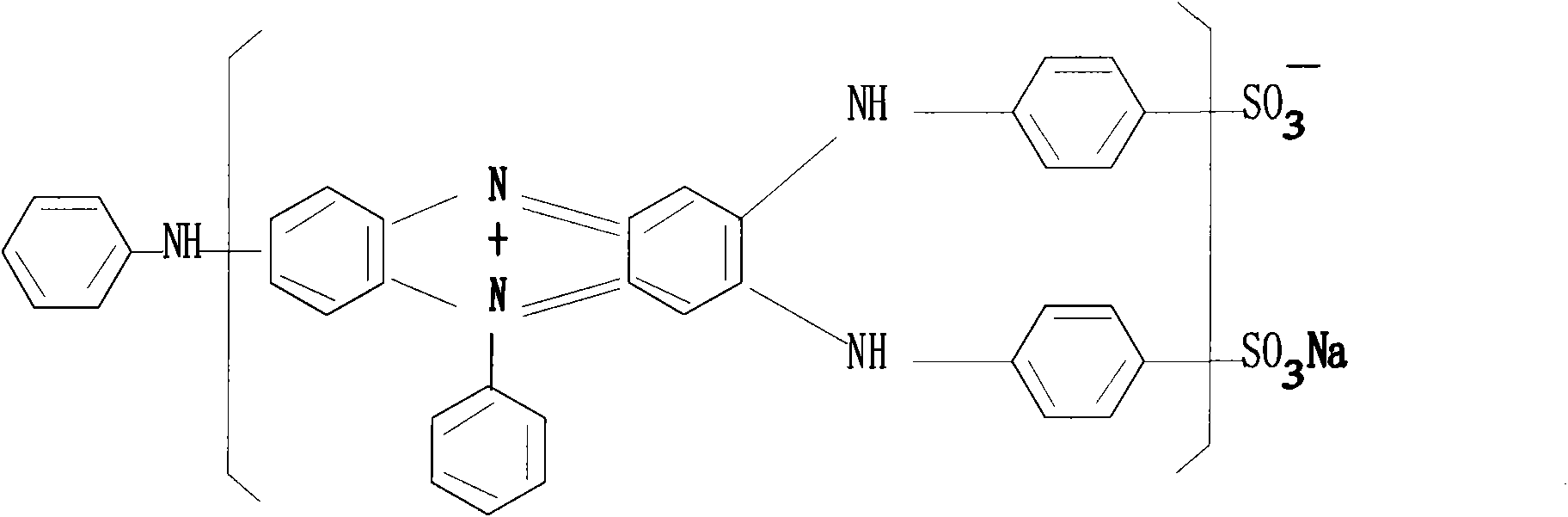

[0029] The invention discloses a method for directly producing water-soluble nigrosine, the specific steps of which are:

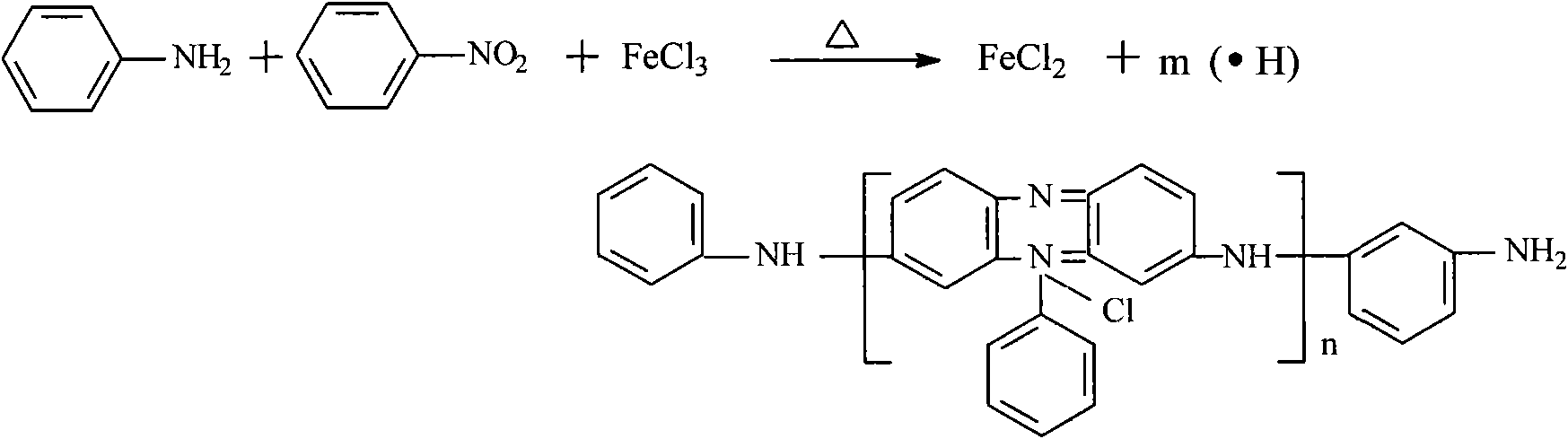

[0030] Step 1, aniline and nitrobenzene are condensed under the catalysis of ferric chloride;

[0031] Step 2, naturally cooling the condensed mixture to normal temperature;

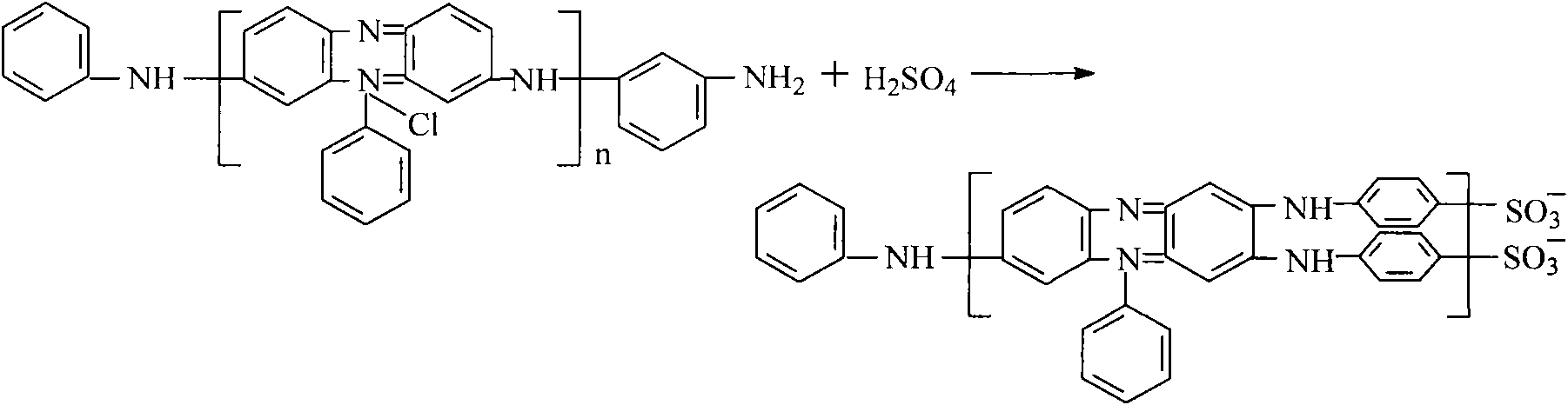

[0032] Step 3, pulverizing the naturally cooled mixture and directly putting it into sulfuric acid for sulfonation reaction;

[0033] Step 4, the sulfonated mixture is placed in cold water for isolation;

[0034] Step 5, performing solid-liquid separation and washing with water on the separated mixture, and then performing dehydration treatment;

[0035] Step 6, neutralizing the dehydrated mixture with sodium hydroxide or sodium carbonate;

[0036] Step 7, drying the neutralized mixture to obtain granular water-soluble nigrosine.

[0037] On the basis of above-mentioned technical scheme, also comprise the following steps:

[0038] Step 8, pulverizing the granular water-soluble n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com