Method for preparing monophosphonate and biphosphonate mixed fire retardant

A flame retardant and phosphonate technology, applied in the preparation of bis-mixed phosphonate flame retardants, can solve the problems of harsh reaction conditions, difficult to control, rare raw materials, etc., and achieve no emission in the production process and low viscosity , the effect of high product utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

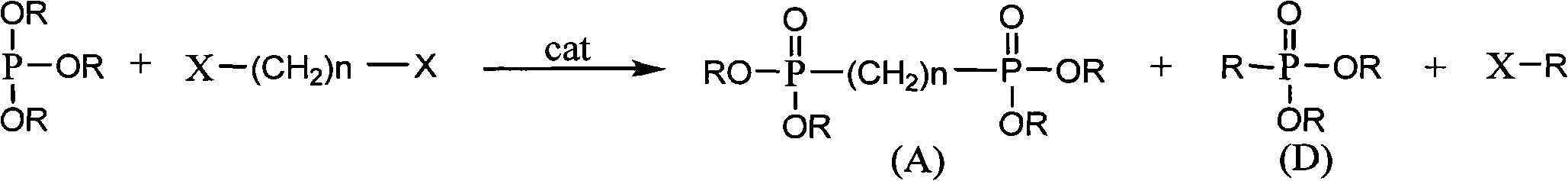

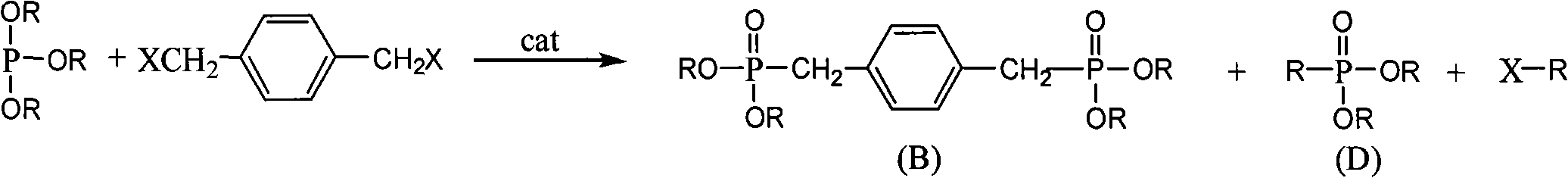

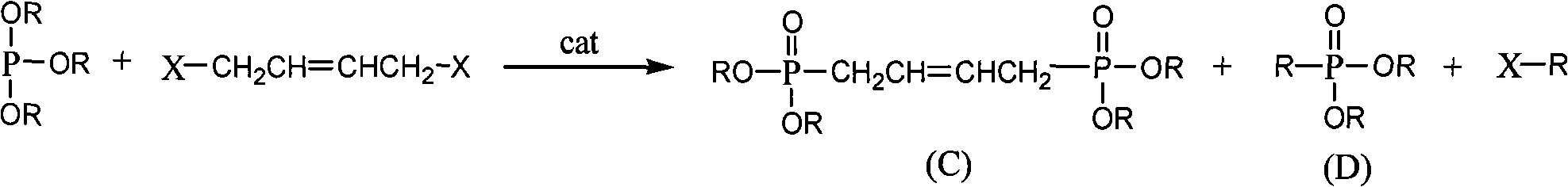

Method used

Image

Examples

Embodiment 1

[0054] Add trimethyl phosphite (P(OCH 3 ) 3 )37.2g, 1,2-dibromoethane (BrCH 2 CH 2 Br) 18.8g, catalyst I 20.25g. Turn on the condensed water, heat and stir, and start to reflux when the temperature rises to about 120°C, continue heating, the temperature gradually rises to 170°C, and the degree of reflux decreases significantly. Continue the reaction, and when there is basically no reflux, keep the temperature at 180-190°C for 1 hour. Atmospheric distillation and suction filtration gave 34.7 g of a colorless and transparent product with a total yield of 93.8%, among which the yield of tetramethyl 1,2-ethylenebisphosphonate was 55.5%.

Embodiment 2

[0056] Add trimethyl phosphite (P(OCH 3 ) 3 )37.2g, 1,2-dibromoethane (BrCH 2 CH 2 Br) 18.8g, catalyst NaI 0.25g. Turn on the condensed water, heat and stir, and start to reflux when the temperature rises to about 120°C, continue heating, the temperature gradually rises to 170°C, and the degree of reflux decreases significantly. Continue the reaction, and when there is basically no reflux, keep the temperature at 180-190°C for 1 hour. Atmospheric distillation and suction filtration gave 34.2 g of a colorless and transparent product with a total yield of 92.4%, among which the yield of tetramethyl 1,2-ethylenebisphosphonate was 63.7%.

Embodiment 3

[0058] Add trimethyl phosphite (P(OCH 3 ) 3 )37.2g, 1,2-dibromoethane (BrCH 2 CH 2 Br) 18.8g, catalyst (CH 3 ) 4NI 0.25g. Turn on the condensed water, heat and stir, and start to reflux when the temperature rises to about 120°C, continue heating, the temperature gradually rises to 170°C, and the degree of reflux decreases significantly. Continue the reaction, and when there is basically no reflux, keep the temperature at 180-190°C for 1 hour. Atmospheric distillation yielded 35.5 g of a colorless and transparent product with a total yield of 95.9%, among which the yield of tetramethyl 1,2-ethylenebisphosphonate was 86.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com