Water-ground-source heat pump system

A ground source heat pump and hot water technology, applied in the field of heat pumps, can solve the problems of high system fouling operation cost, lack of water quality control methods, low heat exchange rate of heat pump units, etc., and achieves high energy utilization efficiency, simple structure, and manufacturing. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

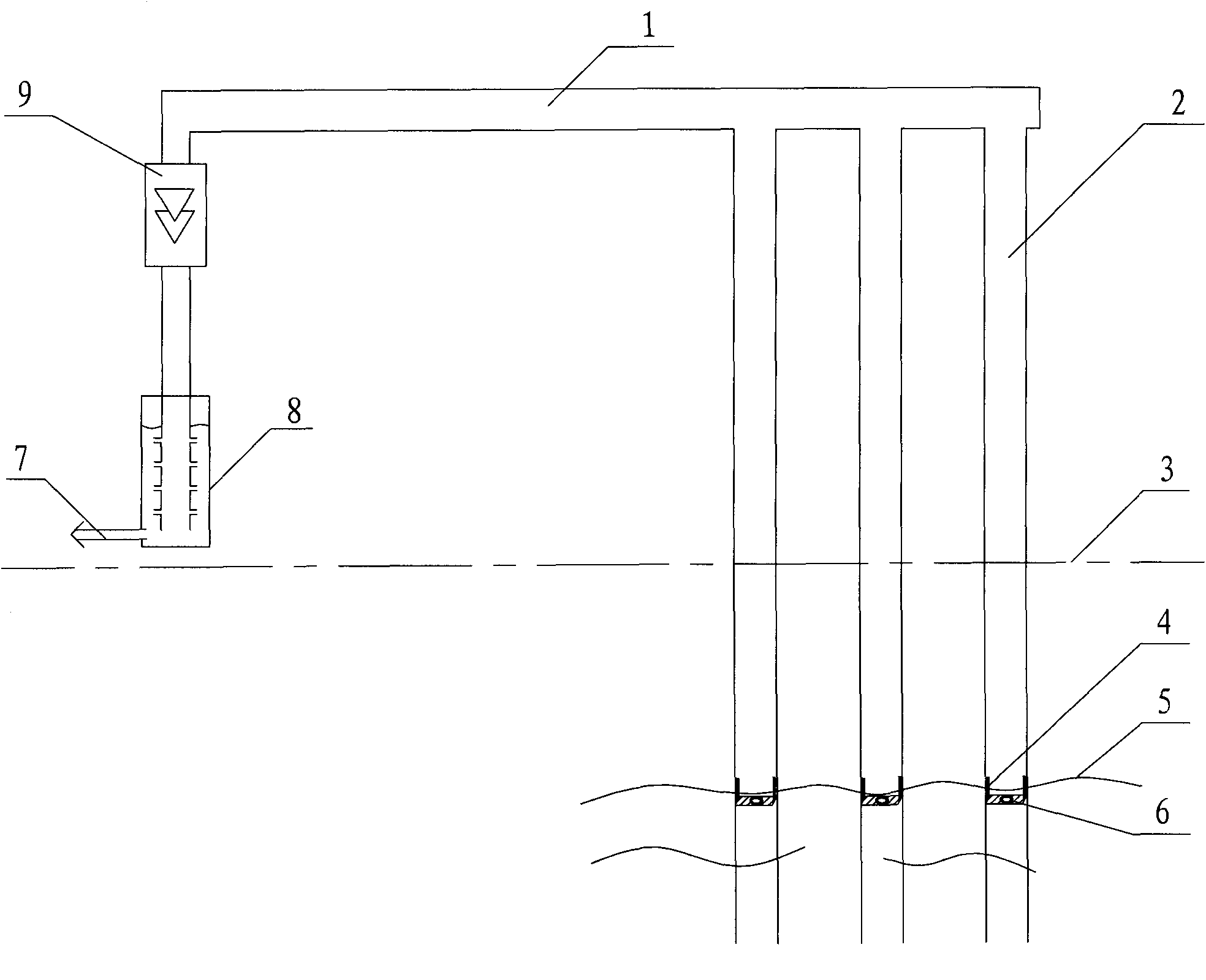

Embodiment 1

[0012] Such as figure 1 As shown, the main structure of the present invention includes a main pipeline 1, a compression pump 9 and a hot water converter 8 with a hot water outlet 7. A compression pump 9 is connected in series on the main pipeline 1, and the outlet of the compression pump 9 is connected to A hot water converter 8 with a hot water outlet 7, the main pipe is also provided with uniformly distributed heat-absorbing branch pipes 2 in parallel, the water inlet end of the heat-absorbing branch pipes is arranged on the lower side of the groundwater level line 5, and the heat-absorbing branch pipes An ultrasonic generator 6 with a float 4 is provided to be suspended under the groundwater level, and the float can ensure that the ultrasonic generator 6 is always in the best working position when the groundwater level changes. Above-mentioned ultrasonic generator 6 that has float 4 can be replaced with the water mist stirring pump that has float.

[0013] During installat...

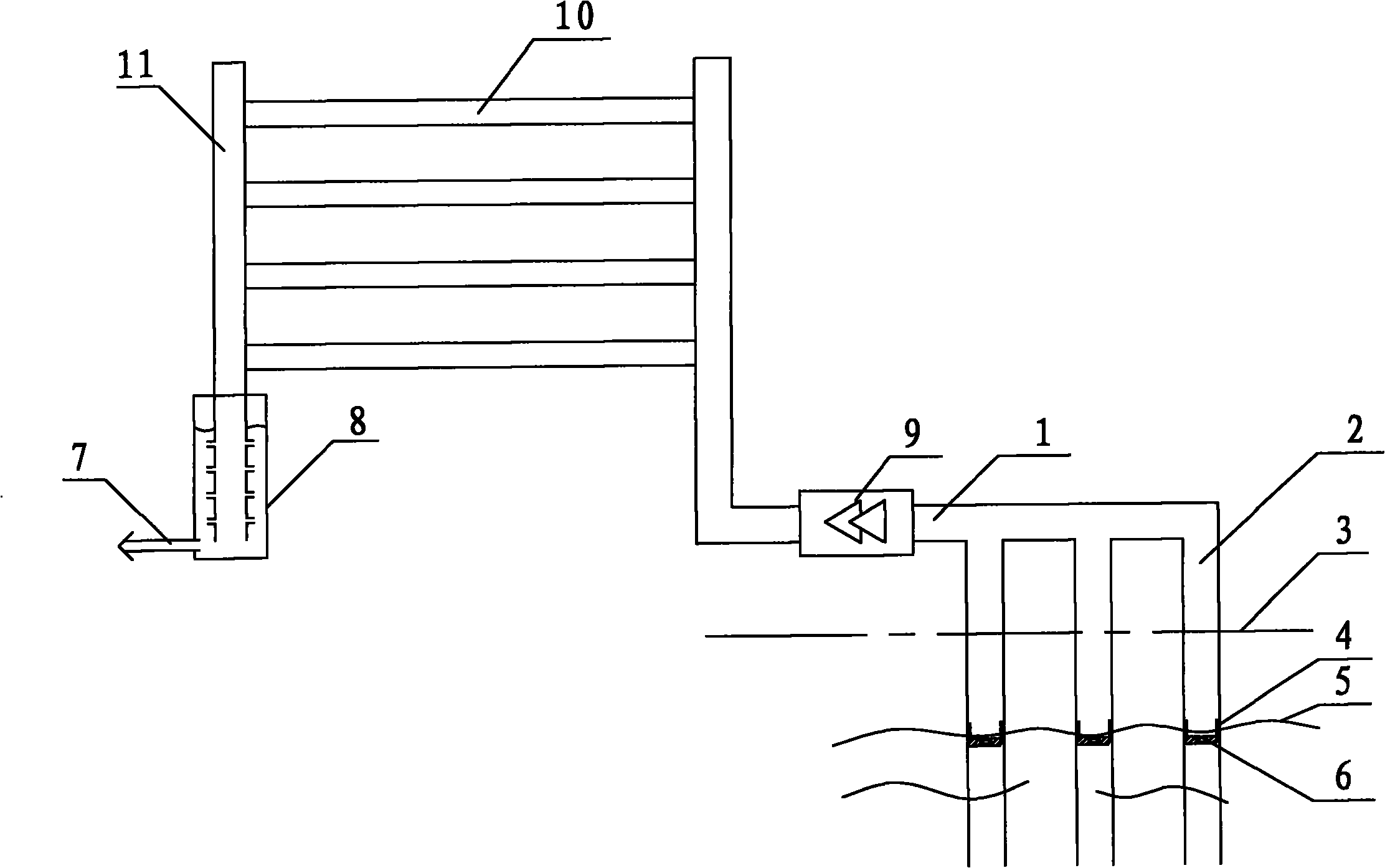

Embodiment 2

[0015] Such as figure 2 As shown, the main structure of the present invention includes a main line pipeline 1, a compression pump 9 and a hot water converter 8 with a hot water outlet 7. A compression pump 9 is connected in series on the main line pipeline 1, and between the main line pipeline and the output pipeline 11 Heat release branch pipes 10 are evenly distributed in parallel, and the outlet of the output pipe 11 is connected to a hot water converter 8 with a hot water outlet 7 . On the main pipeline, there are evenly distributed heat-absorbing branch pipes 2 arranged in parallel. Above-mentioned ultrasonic generator 6 that has float 4 can be replaced with the water mist stirring pump that has float.

[0016] The difference between this embodiment and Embodiment 1 is that when the water mist generated by the ultrasonic generator energizes gradually absorbs heat and becomes superheated steam and passes through the outlet of the compression pump 9, the superheated steam...

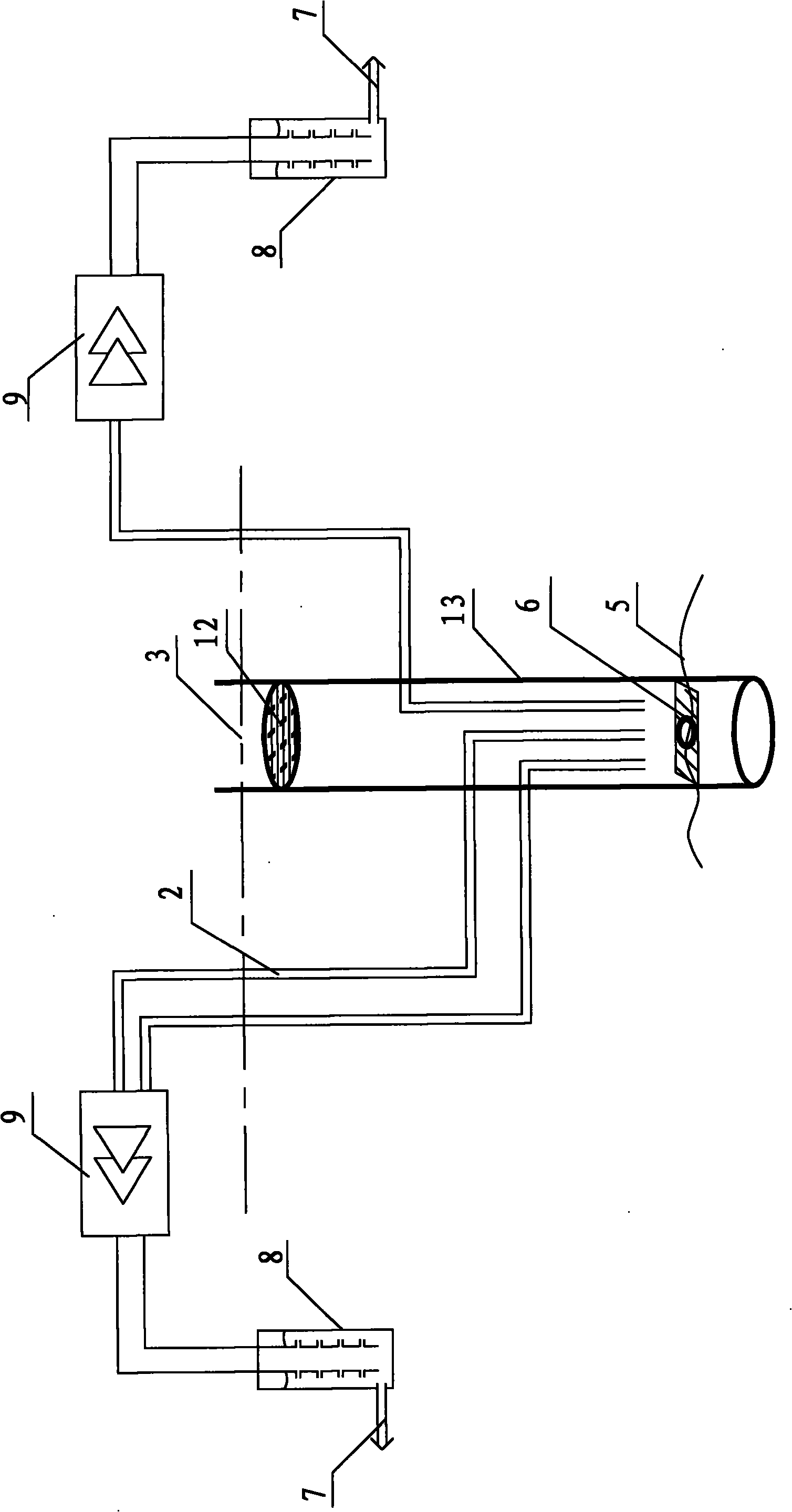

example 3

[0018] Such as image 3 As shown, the main structure of the present invention includes two compression pumps 9 and a hot water converter 8 with a hot water outlet 7, each compression pump is connected with a heat-absorbing branch pipe 2, and the intake end of the heat-absorbing branch pipe is arranged on On the upper side of the underground water level line 5 of the underground well 13, an ultrasonic generator 6 is arranged in the underground well. The above-mentioned ultrasonic generator 6 can be replaced by a water mist stirring pump. Also include well cover 12 among the figure.

[0019] This example can provide heat for multiple users. The principle of atomized water mist in the well entering the heat-absorbing branch pipe to absorb heat and finally turning into superheated steam is the same as Example 1, except that each user has a set of the same equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com