Elemental mercury absorbent, and preparation method and application thereof

A technology of elemental mercury and adsorbent, which is applied in the field of elemental mercury adsorbent and its preparation, can solve complex problems and achieve the effects of simple preparation method, many regeneration times, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Example 1: Adsorbent preparation method (1)

[0023] 1) Place 5 g of carbon nanotubes in 100 ml of ethanol solvent, and ultrasonically oscillate for 240 minutes to prepare a suspension of carbon nanotubes;

[0024] 2) Mix 10ml of 0.005mol / L silver nitrate solution with the carbon nanotube suspension prepared in step 1), and ultrasonically stir for 5 minutes while mixing;

[0025] 3) The mixture obtained in step 2) was filtered, dried at 55° C. for 4 hours, and then heated at 250° C. for 2 hours to obtain a simple mercury adsorbent.

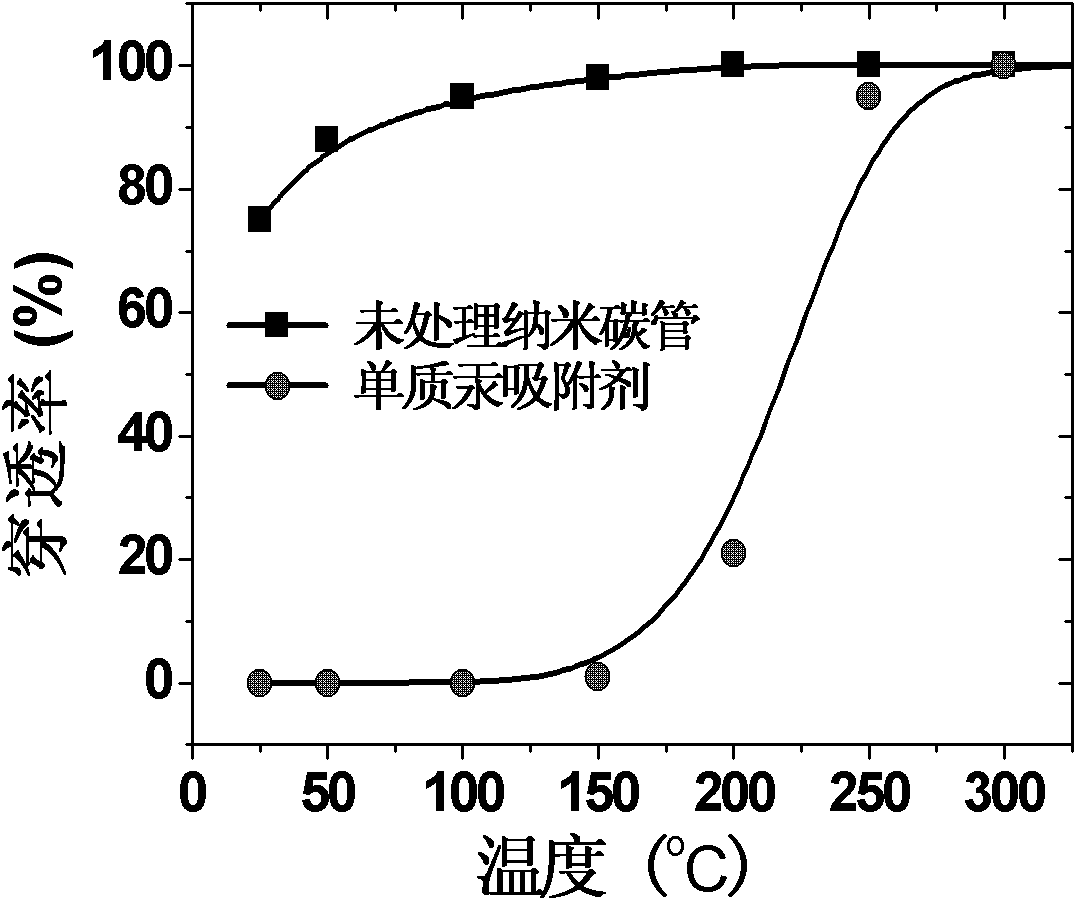

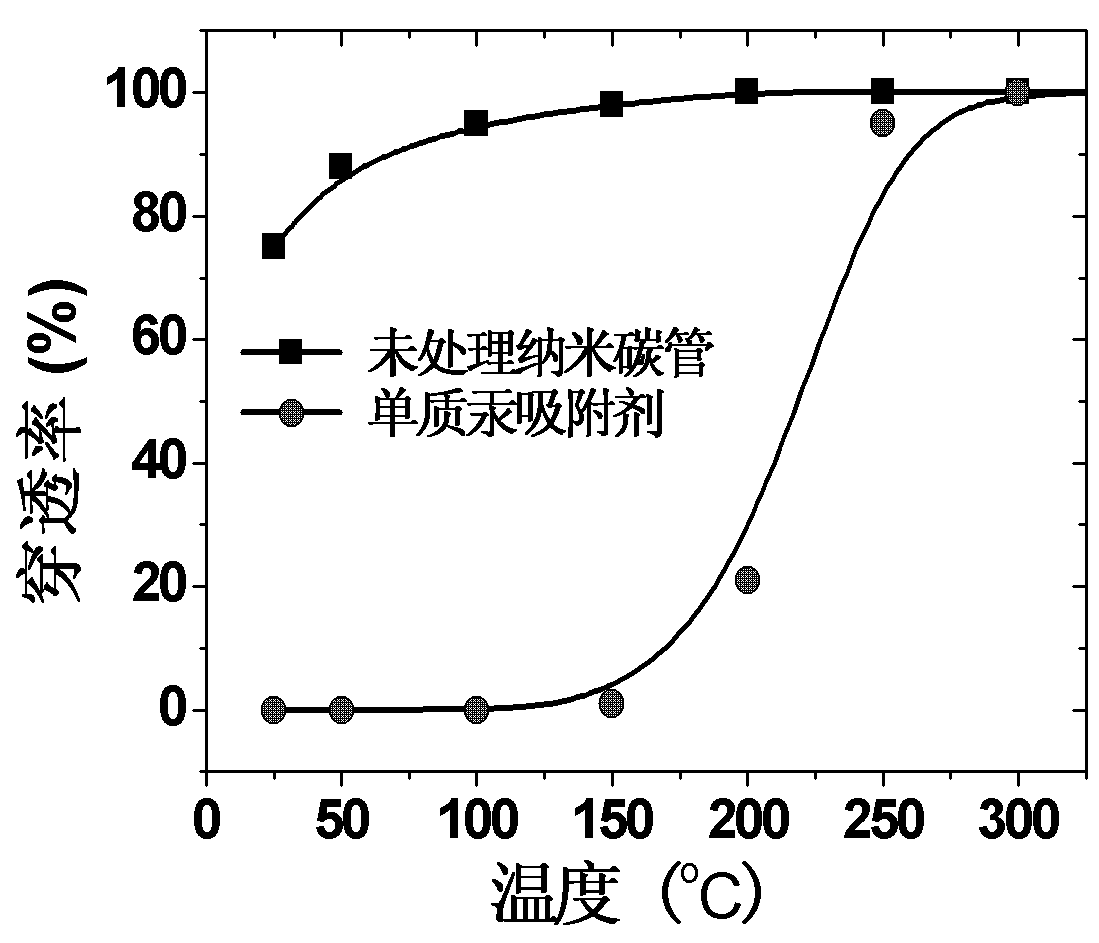

[0026] The adsorbent has a diameter of 10-200nm and a length of 0.01-3mm, and is composed of multi-wall carbon nanotubes with silver clusters evenly distributed on the surface, the diameter of the silver clusters is less than 0.9nm, and the mass content of silver is 0.1%.

example 2

[0027] Example 2: Adsorbent preparation method (two)

[0028] Put 10mg of carbon nanotubes in 10ml of ethanol solvent, and ultrasonically oscillate for 30 minutes to make a suspension of carbon nanotubes;

[0029] 1) 100ml of silver nitrate solution of 1mol / L is mixed with the carbon nanotube suspension prepared in step 1), and ultrasonically stirred while mixing for 60 minutes;

[0030] 2) The mixture obtained in step 2) was filtered, dried at 110° C. for 1 hour, and then heated at 500° C. for 0.5 hour to obtain the elemental mercury adsorbent.

[0031] The adsorbent has a diameter of 10-200nm and a length of 0.01-3mm, and is composed of multi-walled carbon nanotubes with silver clusters evenly distributed on the surface, the diameter of the silver clusters is less than 3nm, and the mass content of silver is 11.3%.

example 3

[0032] Example 3: Adsorbent preparation method (three)

[0033] 1) Place 1 g of carbon nanotubes in 100 ml of ethanol solvent, and ultrasonically oscillate for 150 minutes to prepare a suspension of carbon nanotubes;

[0034] 2) Mix 100ml of 0.1mol / L silver nitrate solution with the carbon nanotube suspension prepared in step 1), and ultrasonically stir for 20 minutes while mixing;

[0035] 3) The mixture obtained in step 2) was filtered, dried at 90° C. for 2 hours, and then heated at 350° C. for 1.5 hours to obtain a simple mercury adsorbent.

[0036] The adsorbent has a diameter of 10-200nm and a length of 0.01-3mm, and is composed of multi-walled carbon nanotubes with silver clusters evenly distributed on the surface, the diameter of the silver clusters is less than 1.3nm, and the mass content of silver is 4.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com