Method for separating lactic acid from fermentation liquor by flocculation and carrying out flocculate comprehensive utilization

A technology for fermentation liquid and floc, which is applied in the field of separation and extraction of lactic acid in fermentation liquid, can solve the problems of safety, lack of comprehensive utilization, waste of resources and the environment, etc., and achieves the effects of reducing cost, good solid-liquid separation effect, and improving yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

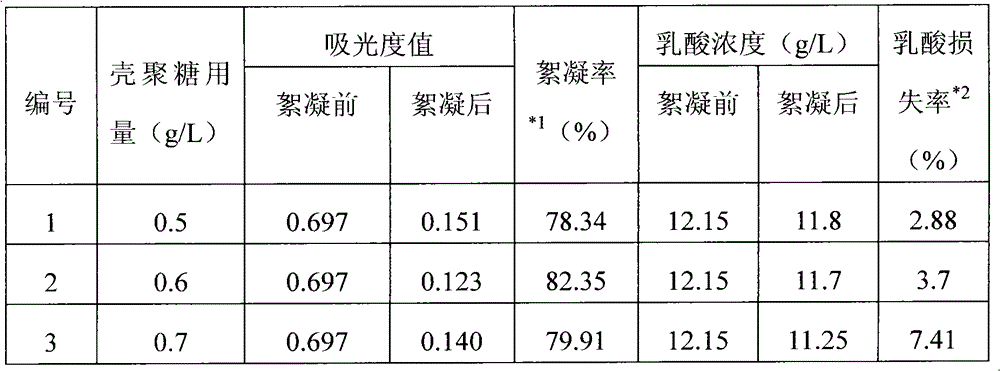

[0018] Take 50ml of fermented liquor of industrial liquor distillers grains, adjust the pH to 5, heat to 30-60°C, add chitosan according to Table 1, stir at normal speed for about 5min to appear obvious flocs, let it settle for 30min, pour out the supernatant After diluting 10 times, measure its absorbance value and lactic acid concentration at 650nm.

[0019] Table 1 Comparison of effects before and after adding chitosan flocculation

[0020]

[0021] *1 Flocculation rate=[(absorbance value before flocculation-absorbance value after flocculation) / absorbance value before flocculation]×100%

[0022] *2 Lactic acid loss rate = [(lactic acid concentration before flocculation - lactic acid concentration after flocculation) / lactic acid concentration before flocculation] × 100%

[0023] Carry out fermentation test according to table 2: industrial liquor distiller's grains 5g, add water according to solid-liquid ratio 1: 10, add 1g chitosan floc, put into 100ml Erlenmeyer flask...

Embodiment 2

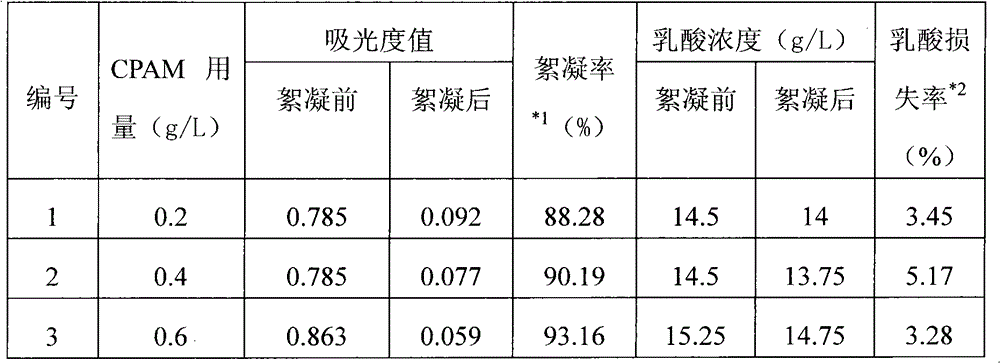

[0027] Take 50ml of fermented liquor of industrial liquor distillers grains, adjust the pH value to 8, heat to 30-60°C, add CPAM according to Table 3, stir at normal speed for about 5min to appear obvious flocs, let it settle for 30min, pour out the supernatant, dilute Measure its absorbance value and lactic acid concentration at 650nm after 10 times.

[0028] Table 3 Comparison of effects before and after adding CPAM flocculation

[0029]

[0030] *1 Flocculation rate=[(absorbance value before flocculation-absorbance value after flocculation) / absorbance value before flocculation]×100%

[0031] *2 Lactic acid loss rate = [(lactic acid concentration before flocculation - lactic acid concentration after flocculation) / lactic acid concentration before flocculation] × 100%

[0032] Carry out the fermentation test according to Table 4: 10g of industrial liquor distillers grains, add water according to the solid-to-liquid ratio of 1:5, add 2g of CPAM flocs, put into a 100ml Erl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com