Preparation method of L-octohydroindoline-2-formic acid

A technology of indoline and formic acid, which is applied in the field of preparation of L-octahydroindoline-2-carboxylic acid, can solve the problems of high raw material prices and no market advantages, and achieve low cost, environmentally friendly process, and clean hydrogenation route Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

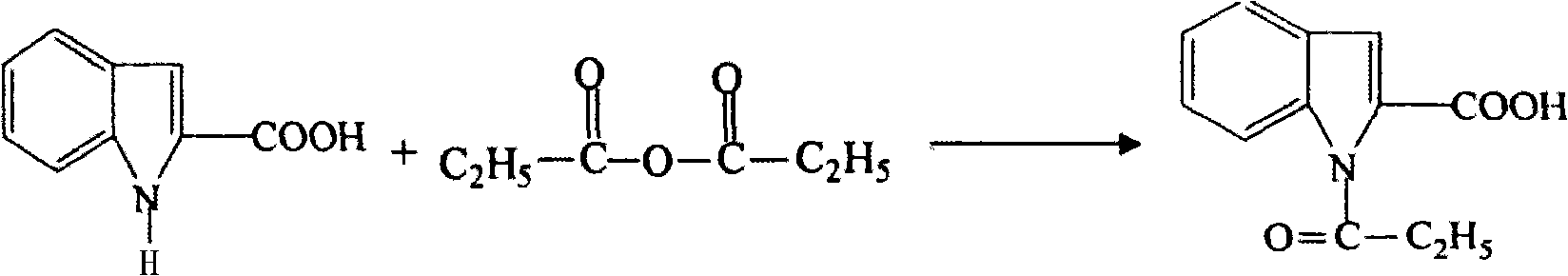

[0006] The preparation method of L-octahydroindoline-2-carboxylic acid:

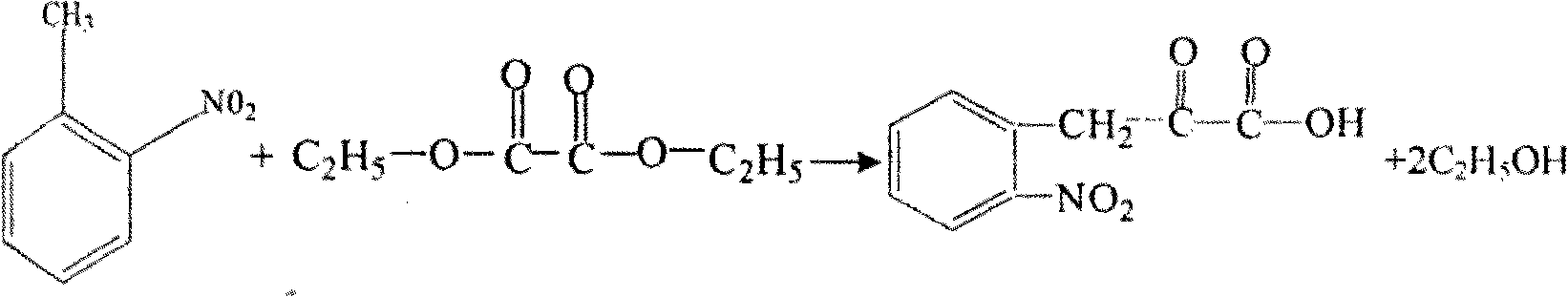

[0007] (1), the condensation process synthesizes o-nitropyruvate:

[0008] The reaction formula is as follows:

[0009]

[0010] C 2 h 5 Na+HCl→C 2 h 5 OH+NaCl

[0011] Add 185 kilograms of diethyl oxalate, 121 kilograms of o-nitrotoluene and 87 kilograms of sodium ethylate to the reaction kettle, add 2000 l of heat to reflux for 3 hours, evaporate the ethanol, add water to the reaction kettle, stir for deep decomposition, and then steam Remove o-nitrotoluene until the reaction solution is clear, adjust the pH to 0.5 with 30% hydrochloric acid after reaching room temperature, spin dry by centrifugation to obtain a solid, and dry it at 60-70°C.

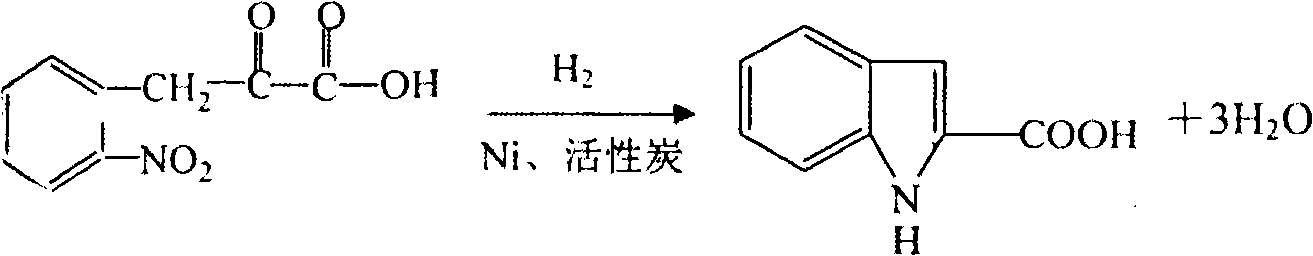

[0012] (2), hydrogenation section prepares indole-2-carboxylic acid:

[0013] The reaction formula is as follows:

[0014]

[0015] Add 81kg of o-nitropyruvate and 600l of 95% ethanol to the reaction kettle, adjust the pH to 7-8 with 30% lye, add ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com