Preparation method and application of terminated-type cation water-borne polyurethane color fixing agent

A water-based polyurethane and cationic technology, used in dyeing, textiles and papermaking, etc., can solve the problems of non-uniform dispersion and difficult reaction control, and achieve the effects of preventing hydrolysis, no effect on color, and increasing smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

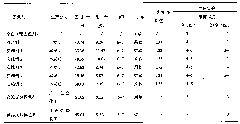

Examples

Embodiment 1

[0026] Example 1: Under the operating conditions of the comparative example, the small molecule chain extender DEG was replaced with 0.44g of capping agent phenol (diluted with acetone to a mass fraction of 30%) and added to the system. After the capping reaction was complete, The amount of water added was 50.86g, and the theoretical solid content was 25.36%, and the light yellow transparent emulsion was obtained.

Embodiment 2

[0027]Example 2: Under the operating conditions of the comparative example, the theoretical R value of the prepolymer was adjusted to 1.58, and the small molecule chain extender DEG was replaced with 1.54g caprolactam (diluted to a mass fraction of 30% with acetone) and added Into the system, after the capping reaction is complete, add 46.27 g of water to obtain a light yellow translucent emulsion with a theoretical solid content of 28.35%.

Embodiment 3

[0028] Example 3: Under the operating conditions of the comparative example, the theoretical R value of the prepolymer was adjusted to 1.72, and the small molecule chain extender DEG was replaced with 1.63g end-capping agent methyl ethyl ketone oxime (diluted to a mass fraction of 30% with NMP) After adding to the system, the temperature of the water bath was raised to 80°C. After the end-capping reaction was complete, the amount of water added was 44.32g, and a light yellow transparent emulsion with a theoretical solid content of 32.68% was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com