Butyl rubber composition and method for producing butyl rubber adhesive tape by using same

A technology of butyl rubber and composition, applied in the field of butyl rubber composition, can solve the problems of unstable production, uncontrollable, difficult vulcanization degree and final performance index, etc. The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A butyl rubber composition for producing butyl rubber adhesive tape, based on the total weight of the composition, it consists of the following components: butyl rubber 24.1%; styrene-isoprene-styrene embedded Segment copolymer 6.0%; processing oil 15.1%; tackifying resin 30.2%; zinc oxide 0.2%; sulfur 0.3%; carbon black 9.0%; clay 15.0%; alkylphenol antioxidant 0.2%.

Embodiment 2

[0032] A butyl rubber composition for producing butyl rubber adhesive tape, based on the total weight of the composition, it consists of the following components: butyl rubber 24.1%; styrene-butadiene-styrene block Copolymer 6.0%; processing oil 10.1%; butyl rubber with a molecular weight of 1000-3000 5%; tackifying resin 30.2%; zinc oxide 0.2%; sulfur 0.3%; carbon black 9.0%; clay 15.0%; alkylphenol antioxidant Agent 0.2%.

Embodiment 3

[0034] The present embodiment provides a kind of butyl rubber adhesive tape, which is produced according to the following method by the butyl rubber composition of embodiment 1:

[0035] (1) Add each raw material to the feeder of the screw extruder, control the temperature of each section of the twin-screw extruder, the temperature of the feeding section is room temperature ~ 40°C, the temperature of the compression section is 90 ~ 100°C, and the metering section is 80 ~ 90°C , the melt pressure is 0.2-0.3MPa, the host speed is 200-300rpm, and the processing time is 30min. Tape is obtained through the die of the extruder, and a strip-shaped semi-finished product is obtained from the roll;

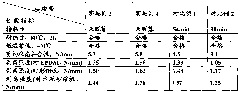

[0036] (2) Place the semi-finished product in step (1) at 120-160°C, heat-preserve and vulcanize for 3 hours to obtain the adhesive tape. The properties of the adhesive tape are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com