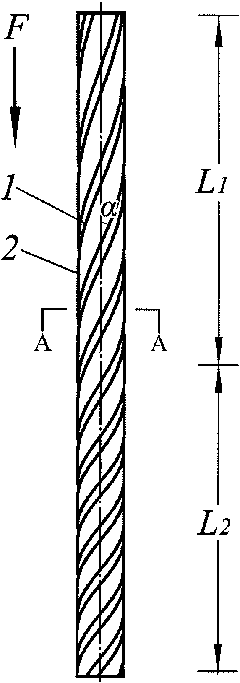

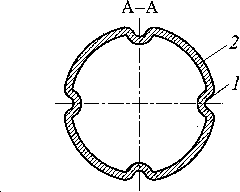

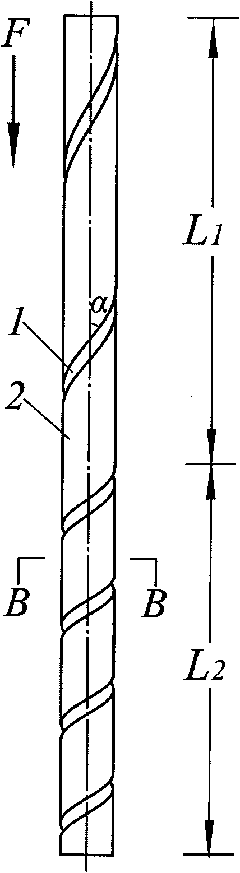

Field synergy effect-based cracking furnace tube

A cracking furnace tube and field synergy technology, applied in cracking, non-catalytic thermal cracking, petroleum industry and other directions, can solve the problems of shortening the coke cleaning cycle, increasing the flow resistance in the tube, occupying the effective volume, etc., to reduce heat transfer resistance, The effect of reducing coking and reducing heat transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] According to the technical principle of the present invention, the ethylene cracking experiment test was carried out, and the comparison test was carried out with the smooth circular tube in the same cracking furnace and under the same operating conditions, and the outlet temperature, ethylene yield and pressure drop in the tube were measured experimentally. The operating conditions are shown in Table 1, and the test results are shown in Table 2 and Table 3.

[0036] Table 1 Test operating conditions

[0037]

[0038]

[0039] Table 2 Test result 1 (initial stage of operation)

[0040] project

Furnace tube of the present invention

Furnace tube of the present invention

Smooth round tube

Tube surface temperature

990℃

925℃

1015℃

[0041] project

Furnace tube of the present invention

Furnace tube of the present invention

Smooth round tube

output temperature

855℃

809℃

812℃

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com